Boron affinity monolithic column based on atom transfer radical polymerization and preparation method thereof

An atom transfer and monolithic column technology, applied in the field of boron affinity monolithic column and its preparation, can solve the problem of low adsorption capacity of boron affinity monolithic column, and achieve the effect of high affinity, stable physical and chemical properties, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

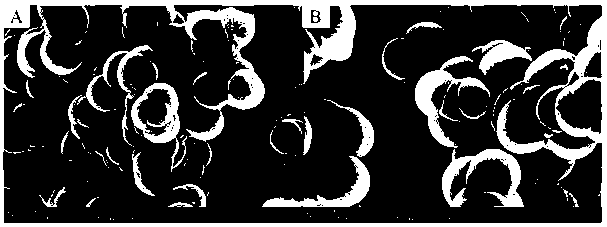

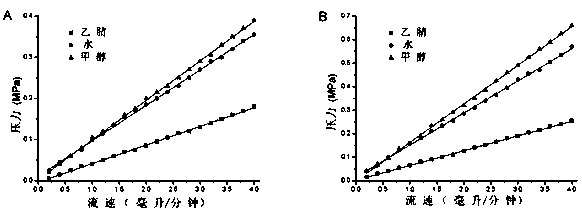

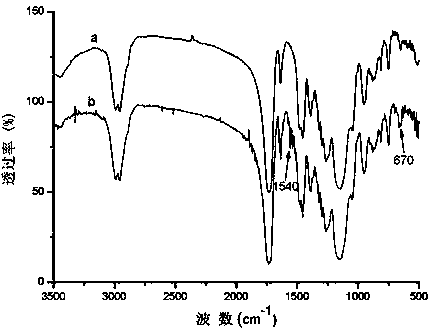

[0037] First, the basic porous polymer monolithic column was prepared by ATRP reaction, and then the boron-affinity polymer chain was grafted on the base column by ATRP reaction to prepare the boron-affinity monolithic column, and the basic porous polymer monolithic column and boron-affinic Carry out scanning electron microscopy analysis and characterization, infrared characterization and nitrogen adsorption analysis with the monolithic column. The specific operation steps are as follows:

[0038] Preparation method of boron affinity monolithic column based on two-step ATRP reaction:

[0039] The first step: 0.53% of cuprous bromide (both mass fractions) and 41.4% of ethylene glycol dimethacrylate are dissolved in a mixture of methanol and 26.0% n-hexane with a mass fraction of 31.2%, and ultrasonic at room temperature (Ultrasonic electric power 150 watts) until the cuprous bromide is evenly distributed, add 0.23% ethyl 2-bromopropionate, and after nitrogen gas for 10 minutes,...

Embodiment 2

[0051] Small molecule separation experiment to study the specific adsorption performance of boron-affinity monolithic column based on two-step ATRP reaction on cis-dihydroxy small molecule substances. The specific operation steps are as follows:

[0052] The boron affinity monolithic column based on the two-step ATRP reaction was synthesized with the above method (Example 1) for the separation of cis-dihydroxy small molecular substances.

[0053] Prepare mobile phase: mobile phase one is acetic acid-ammonia solution (pH=8.5) with 0.4% (v / v) acetic acid concentration, mobile phase two is acetic acid solution (pH=3.1) with 0.4% (v / v) concentration .

[0054] Use mobile phase 1 to prepare a mixed solution of ferulic acid-rutin, ferulic acid-rosmarinic acid, epinephrine-phenylephrine at a concentration of 1 ppm. The boron affinity monolithic column was used as a chromatographic column, and the above solution was chromatographically separated by HPLC-UV.

[0055] The chromatogra...

Embodiment 3

[0058] Glycoprotein separation experiment to study the specific adsorption performance of the boron affinity monolithic column based on the two-step ATRP reaction for proteins containing cis-dihydroxyl groups. The specific operation steps are as follows:

[0059] The same method as above (Example 1) was used to synthesize a boron affinity monolithic column based on ATRP reaction for separating cis-dihydroxy-like proteins.

[0060] Prepare mobile phase: mobile phase one is acetic acid-ammonia solution (pH=8.5) with 0.4% (v / v) acetic acid concentration, mobile phase two is acetic acid solution (pH=3.1) with 0.4% (v / v) concentration .

[0061] Use mobile phase one to prepare a mixed solution of lysozyme-horseradish peroxidase, lysozyme-DNase B, and lysozyme-transferrin at a concentration of 10 ppm. The boron affinity monolithic column was used as a chromatographic column, and the above solution was chromatographically separated by HPLC-UV.

[0062] The chromatographic conditio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com