Graphene oxide/prussian blue nanoparticle composite material solid-phase micro-extraction probe as well as preparation method and application thereof

A technology of Prussian blue and nanoparticles, which is applied in the field of graphene oxide/Prussian blue nanoparticle composite solid-phase microextraction probes and its preparation, can solve the problem of restricting the development and application of solid-phase microextraction technology, and it is difficult to meet the separation and analysis requirements , limited application range of extraction and other issues, to achieve the effect of simple and fast preparation steps, wide application range and controllable thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The preparation of embodiment 1 graphene oxide / Prussian blue nanoparticle composite material

[0046] Preparation of graphene oxide / Prussian blue nanoparticle composite material: The composite material is synthesized according to the literature (Chem. Sci.2015, 6, 4029), and the synthesis method is as follows:

[0047] 200 mg of graphene oxide was placed in 50 mL of ultrapure water and ultrasonicated for 30 min to obtain a uniform graphene oxide dispersion. Then, 170 mg of potassium ferricyanide and 50 mL of 0.01 mol / L hydrochloric acid solution were gradually added to the graphene oxide dispersion under stirring to obtain a uniformly mixed reaction mixture. The reaction mixture was placed in a reaction kettle and placed in an oven at 85° C. for 24 h. After the reaction was completed, the product was collected by centrifugation, and the product was dried in a vacuum oven at 60°C for 12 hours to finally obtain a graphene oxide / Prussian blue nanoparticle composite material...

Embodiment 2

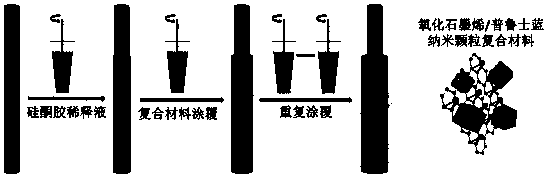

[0048] Example 2 Preparation of Graphene Oxide / Prussian Blue Nanoparticle Composite Solid Phase Microextraction Probe

[0049] The preparation of solid-phase microextraction probe of graphene oxide / Prussian blue nanoparticle composite material, the preparation process is as follows figure 2 , including the following steps:

[0050] S1. Pretreatment of stainless steel fibers: After cutting the stainless steel fibers into 2-3 cm lengths, soak them in ultrapure water, methanol, and acetone in sequence, and sonicate them for 30 min, take them out and dry them naturally.

[0051] S2. Preparation of neutral silicone gel diluent: mix 0.5g of neutral silicone gel with 1.0mL o-xylene, stir well, and sonicate for 5 minutes to obtain a neutral silicone gel diluent.

[0052] S3. Put the pretreated stainless steel fiber into the diluent of neutral silicone glue, take it out, dry the visible droplets on the surface of the stainless steel fiber with filter paper, and obtain a stainless ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com