Method for preparing reduced graphene oxide by using dielectric barrier discharge plasma

A technology of dielectric barrier discharge and plasma, which is applied in the direction of graphene, single-layer graphene, chemical instruments and methods, etc., can solve the problems of less processing capacity, easy agglomeration, and low output, and achieve low resource and energy consumption, Prevent aggregation and re-growth, high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

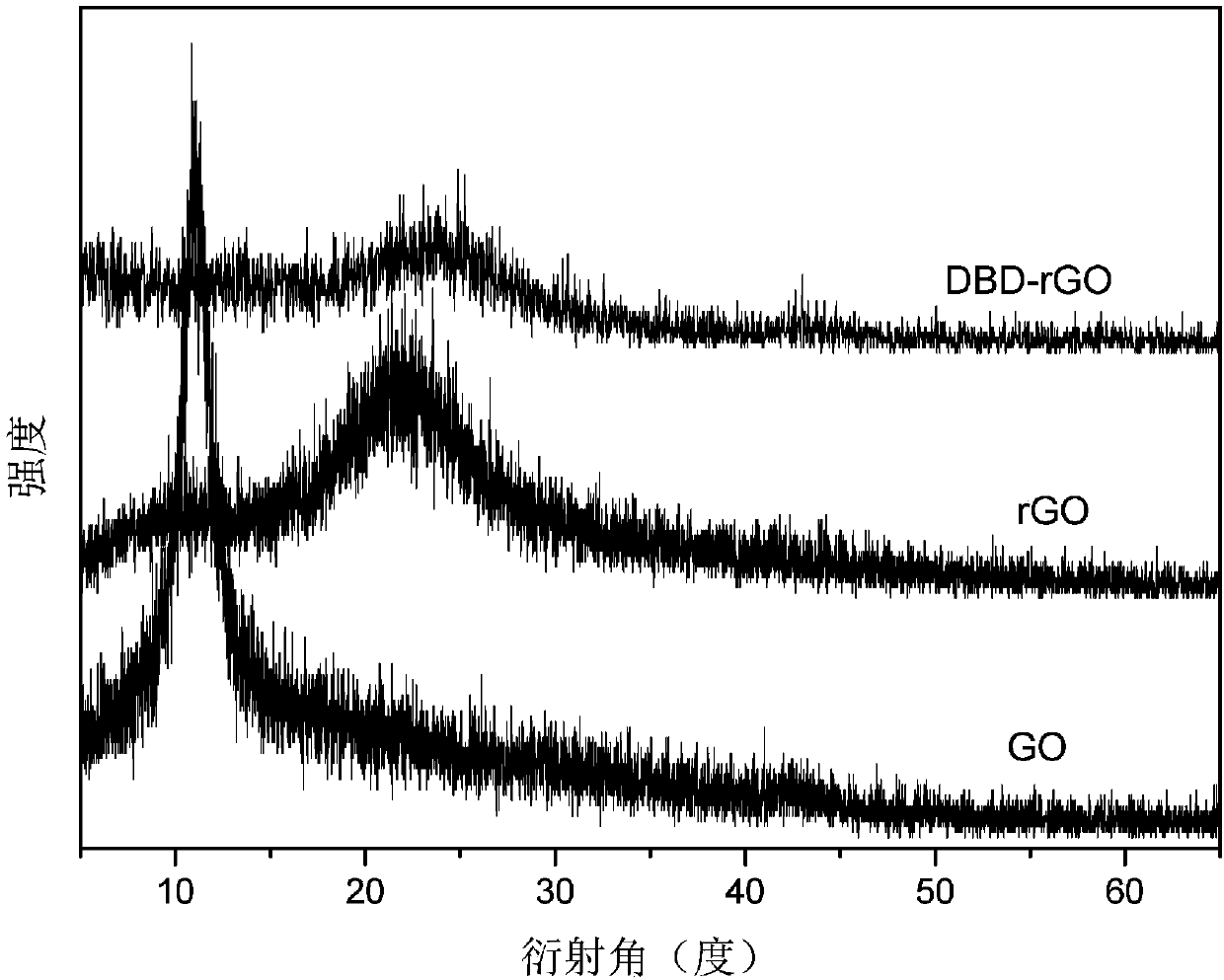

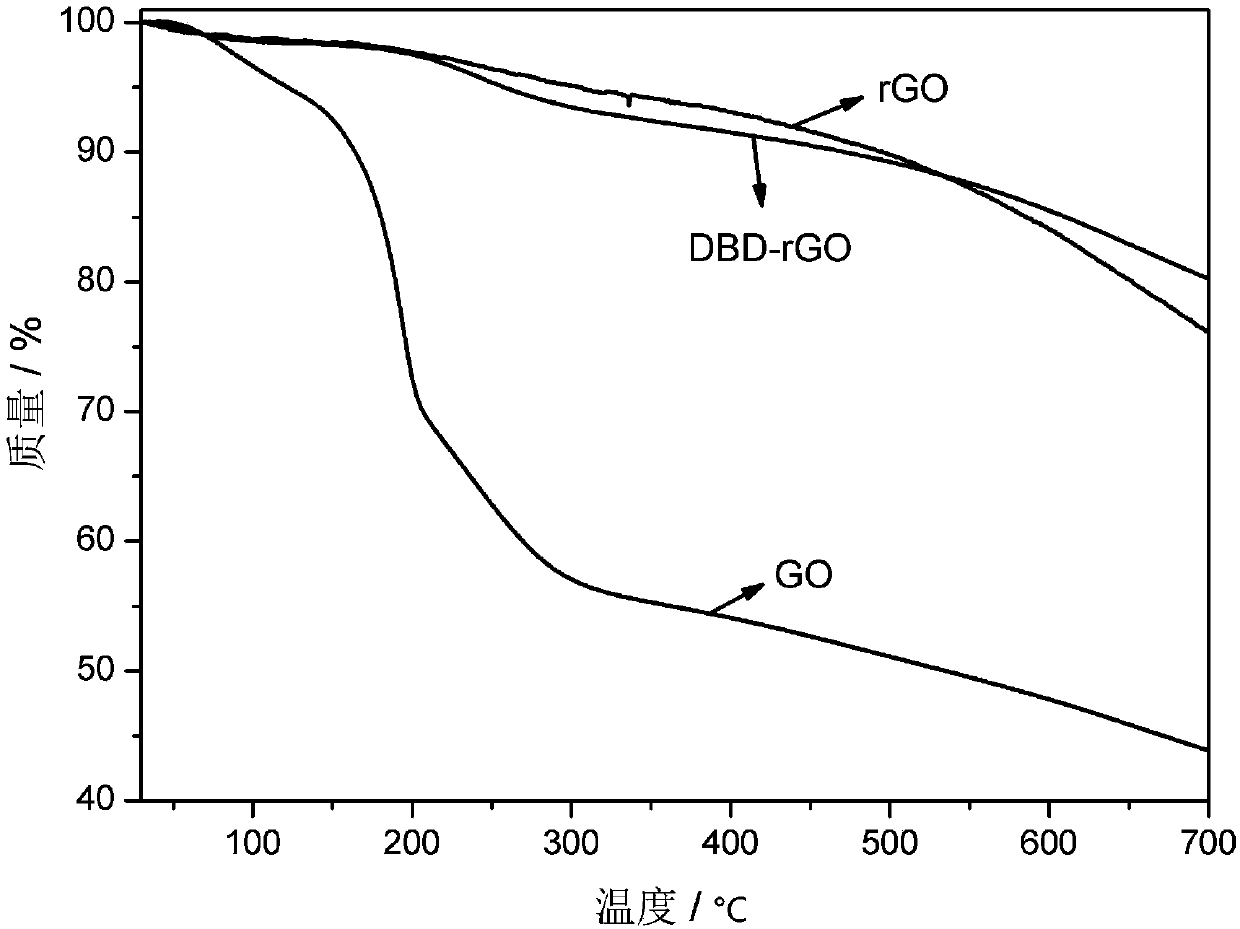

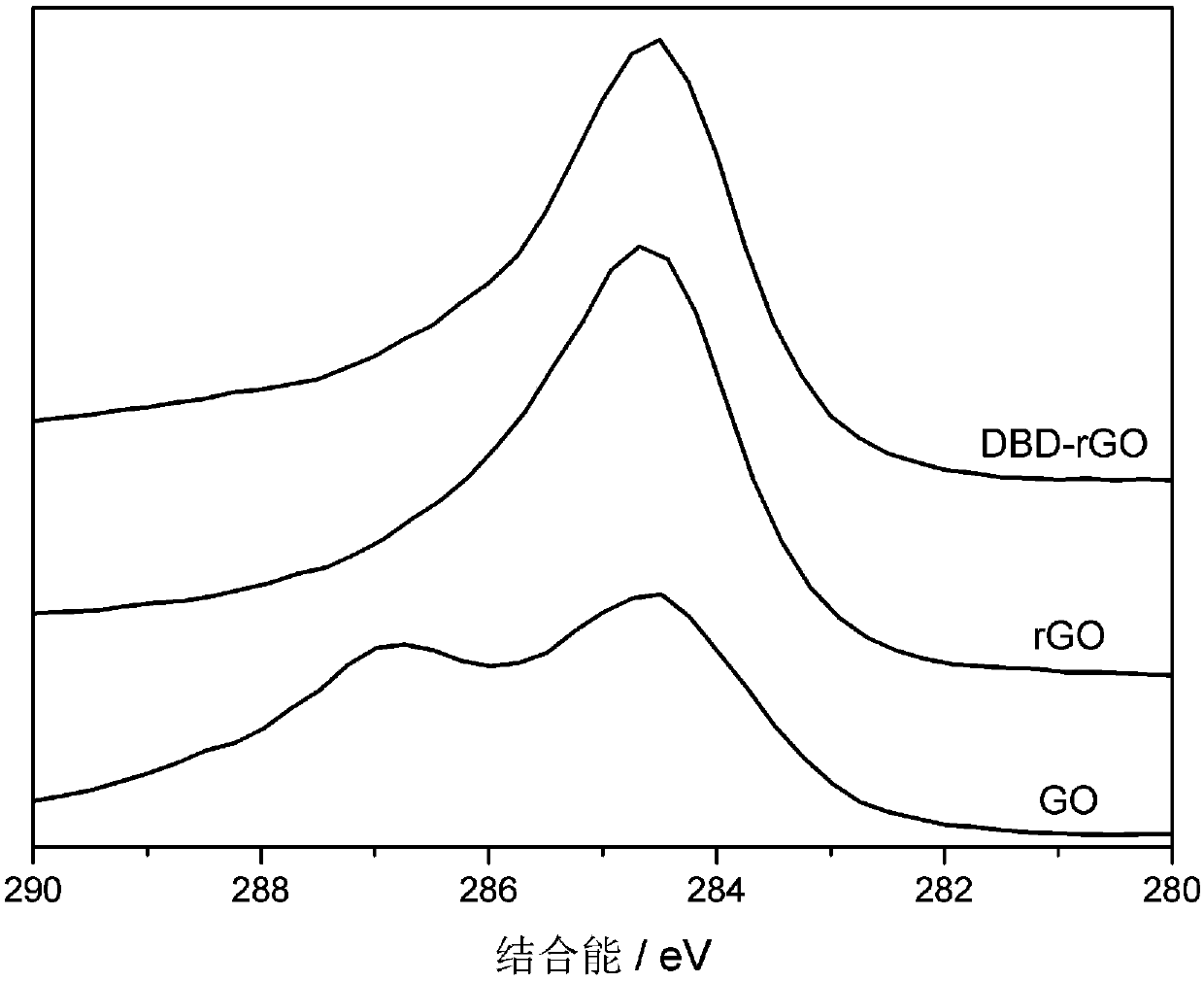

[0036] The multilayer graphene oxide powder prepared by the Improved method is placed between the two electrodes of the plate-plate dielectric barrier discharge device, and argon gas is passed in at room temperature (20-30°C) as the discharge gas, and the high-voltage power supply is turned on to adjust the working conditions. The voltage was 1000V, the working current was 1.0A, and the discharge treatment was performed at room temperature for 3 minutes. The obtained product was characterized and analyzed by XRD, TG, and XPS, which proved that graphene oxide was reduced. The carbon source conversion rate in the preparation process is 90%, and the specific surface area is 410m 2 / g. The characterization results are shown in figure 1 , 2 and 3.

Embodiment 2

[0038] Place the multilayer graphene oxide sheet prepared by the Staudenmaier method between the two electrodes of the plate-plate dielectric barrier discharge device, pass nitrogen gas as the discharge gas at room temperature (20-30°C), turn on the high-voltage power supply, and adjust the operating voltage To 500V, working current to 1.0A, discharge treatment at room temperature for 60min, the obtained product was analyzed by XRD and TG, which proved that graphene oxide was reduced. The conversion rate of carbon source in the preparation process is 96%, and the specific surface area is 467m 2 / g.

Embodiment 3

[0040] Place the single-layer graphene oxide powder prepared by the Hummers method between the two electrodes of the point-plate dielectric barrier discharge device, feed air at room temperature (20-30°C) as the discharge gas, turn on the high-voltage power supply, and adjust the working voltage To 1000V, working current to 1.0A, discharge treatment at room temperature for 60min, the obtained product was analyzed by XRD and TG, which proved that graphene oxide was reduced. The carbon source conversion rate in the preparation process is 92%, and the specific surface area is 489m 2 / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com