Method for Escherichia coli whole cell catalyzed production of phloretin

A technology of Escherichia coli and phloretin, applied in the field of phloretin biosynthesis, can solve problems such as serious pollution and serious chemical pollution, and achieve the effects of good purity, high content and easy production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

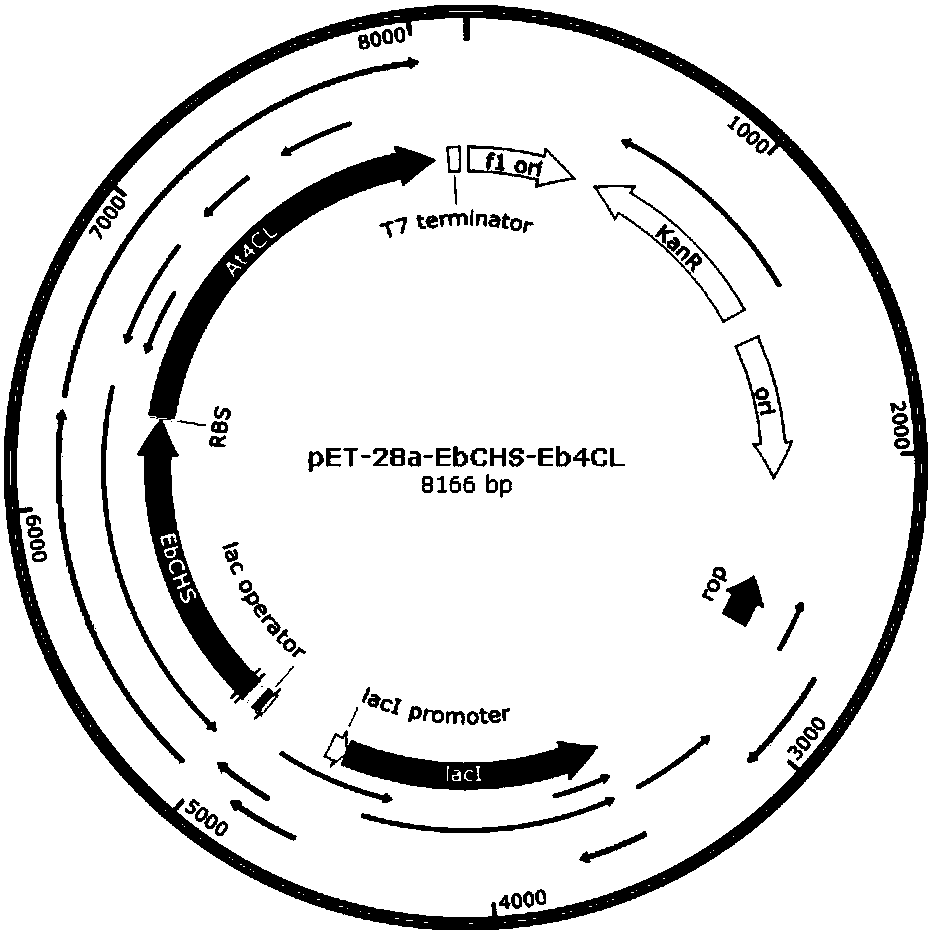

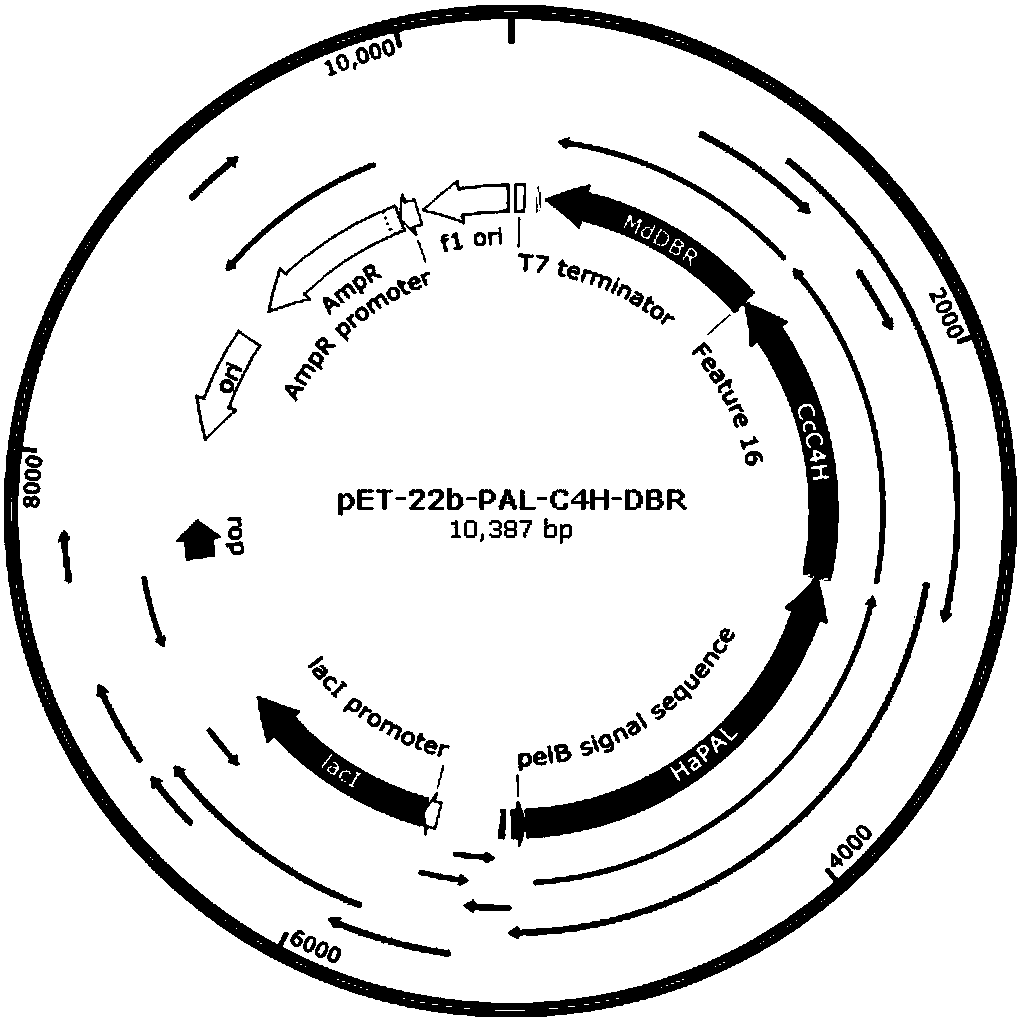

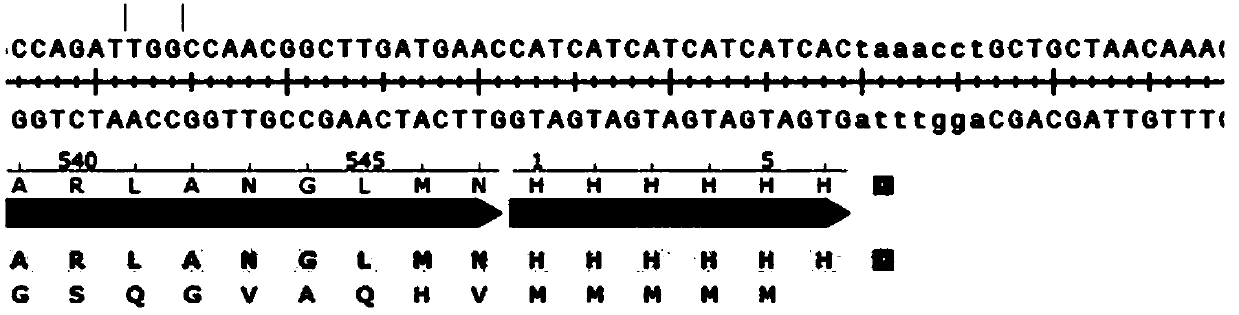

[0036] Example 1 Plasmid construction method.

[0037] According to the amino acid sequence of the corresponding expressed gene and the codon preference of Escherichia coli, this patent optimizes the nucleic acid sequence of the gene, and sends it to a commercial gene synthesis company to synthesize the expressed gene, and integrates two or more genes into the expression vector pET-28a or pET On -22b, specifically, the expression genes of 4-coumaric acid coenzyme A ligase and chalcone synthase are constructed on the vector pET-28a, as shown in Figure 1(a), phenylalanine ammonia lyase, cinnamon The expression genes of acid-4-hydroxylase and double bond reductase are constructed on the vector pET-22b, as shown in Figure 1(b), the expression genes on the same vector share a T7 promoter, at the end of the expression gene, before the terminator Modify the N-terminal primer, add 6×his gene sequence (CAT CATCAT CAT CAT CAT) to the primer, see Figure 1(c), and connect the expressed ge...

Embodiment 2

[0038] Embodiment 2 Whole cell catalyzes the synthesis of phloretin

[0039] A method for catalyzed production of phloretin by Escherichia coli whole cells:

[0040] 1) 37°C, 220rpm, in LB medium supplemented with corresponding resistance, culture Escherichia coli overnight;

[0041] 2) Transfer to 20mL, 37℃, 220rpm, LB medium, culture to OD 600 = about 1;

[0042] 3) Transfer to 800mL large bottle of 2YT medium, culture at 37°C, 220rpm until OD 600 = about 0.8;

[0043] 4) 16°C, 220rpm, IPTG induction, 16h-18h, harvest bacteria;

[0044] 5) Suspend with phosphate buffer and concentrate 20 times;

[0045] 6) Add the substrate, react at 37° C., 220 rpm for 24 hours, and collect the produced phloretin.

[0046] Note: LB (Luria-Bertani) medium:

[0047] Liquid medium: tryptone: 1%, yeast extract: 0.5%, NaCl: 1%, pH7.5

[0048] Solid medium: add 1.5% agar powder to LB liquid medium

[0049] 2YT medium: tryptone: 1.6%, yeast extract: 1%, NaCl: 0.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com