Preparation method of multifunctional biodegradable oil-water separation film

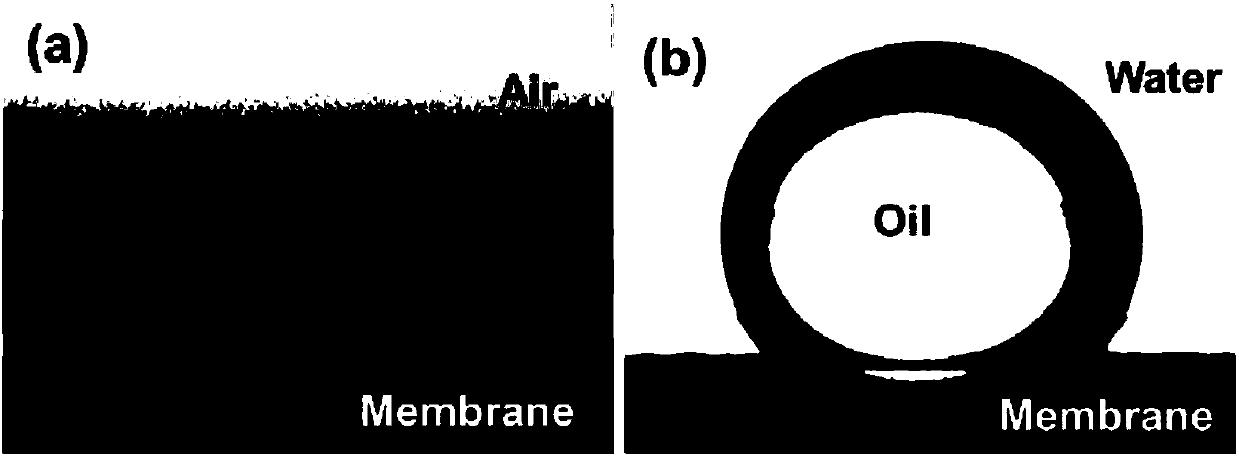

An oil-water separation membrane and biodegradation technology, which is applied in the field of preparation of biodegradable oil-water separation membranes, can solve the problems of secondary pollution and water pollution of organic dye adsorption materials, achieve short separation time, high separation efficiency, and wide application range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Preparation method of biodegradable oil-water separation membrane with multifunctional application based on cellulose

[0045] (1) Preparation of cellulose solution

[0046] Firstly, cellulose fibers such as cotton, wood pulp, and bamboo pulp were activated, that is, cellulose fibers such as cotton, wood pulp, and bamboo pulp were soaked in water, methanol, and dimethylacetamide (DMAc) for 1 hour in sequence. Suction filtration was performed to remove the soaking solvent left in the cellulose, and finally the activated cellulose was dissolved in a solvent system with a DMAc / LiCl ratio of 92:8 to obtain a 1.5wt% cellulose solution.

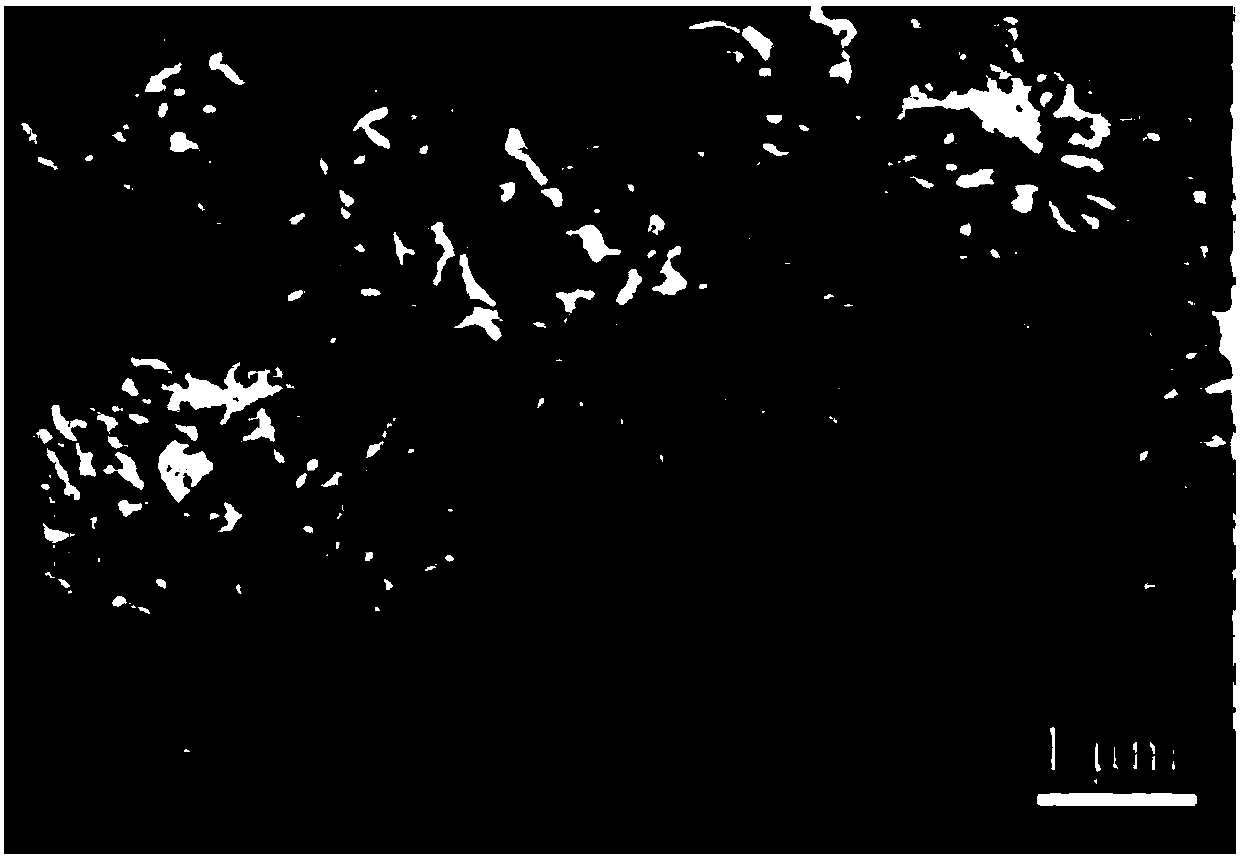

[0047] (2) Preparation of cellulose nanofiber membrane by electrospinning

[0048] Tap water was used as the coagulation bath, the prepared cellulose solution was filled into the syringe, and then spun at a propulsion speed of 0.35 mL / min, the positive and negative voltages were set at 21 KV and -1KV, respectively, and the cellulose solutio...

Embodiment 2

[0054] Preparation method of biodegradable oil-water separation membrane with lignin as substrate for multifunctional application

[0055] (1) Preparation of lignin solution

[0056] First, activate the lignin, soak the lignin in water, methanol, and dimethylacetamide (DMAc) for 1.5 hours in sequence, each soaking is accompanied by suction filtration to remove the soaking solvent in the lignin, and finally the activated lignin Lignin was dissolved in a solvent system with a DMAc / LiCl ratio of 93:7 to obtain a 1 wt% lignin solution.

[0057] (2) Preparation of lignin nanofiber membrane by electrospinning

[0058] Using tap water as a coagulation bath, put the prepared lignin solution into a syringe, and then spin at a propulsion speed of 0.35 mL / min, with positive and negative voltages set at 21 KV and -1KV, respectively, on a rotating metal roller. Aluminum foil is used as a collection device, and the roller curls the silk into a film, and the solvent is removed to obtain a ...

Embodiment 3

[0062] Preparation method of applied biodegradable oil-water separation membrane with chitin as matrix

[0063] (1) Preparation of chitin solution

[0064] First, activate chitin, soak chitin in water, methanol, and dimethylacetamide (DMAc) for 1.5 hours in sequence, each soaking is accompanied by suction filtration to remove the soaking solvent in chitin, and finally the activated chitin Chitin was dissolved in a solvent system with a DMAc / LiCl ratio of 92:8 to obtain a 2wt% chitin solution. (2) Preparation of chitin nanofiber membrane by electrospinning

[0065] Using tap water as a coagulation bath, put the prepared chitin solution into a syringe, and then spin it at a propulsion speed of 0.3 mL / min. Aluminum foil is used as a collection device, and the roller curls the silk into a film, removes the solvent, and prepares a chitin nanofiber film.

[0066] (3) Preparation of biodegradable oil-water separation membranes for multifunctional applications by hydrothermal metho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com