A kind of method that catalyzes guaiacol hydrodeoxygenation to prepare cyclohexanol

A technology of guaiacol and hydrodeoxygenation, which is applied in the direction of catalyst activation/preparation, hydrogenation preparation, chemical instruments and methods, etc. It can solve the problem that the highest yield of the improved technology cannot break through 76%, separation and collection obstacles, and by-products cannot Avoid other problems and achieve the effect of easy separation and purification, convenient operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] Catalyst preparation and hydrogenation method:

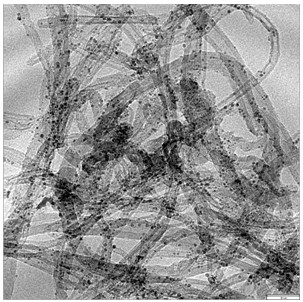

[0039] 1. Pretreatment of the carrier: carbon nanotubes need to be activated by acid. The method is as follows: first prepare a mixture of dilute sulfuric acid with a mass fraction of 30.0% and dilute nitric acid with a mass fraction of 40%, and add the mixed acid solution to a three-necked bottle that has been heated at 700°C at a liquid-solid mass ratio of 20:1. In the multi-walled carbon nanotube powder that was continuously roasted for 6 h (to remove impurities), it was placed in an oil bath at 95°C and continuously refluxed for 6 h. After cooling, it was taken out, washed 5 times with distilled water, and filtered at 110°C Continuous drying in the oven for 12 hours, taking out and grinding into fine powder, passing through a 160-mesh sieve, placing the powder in a tube furnace under nitrogen protection, continuously roasting at 400 °C for 3 h, and then cooling to room temperature to form the processed modified powder...

Embodiment 1

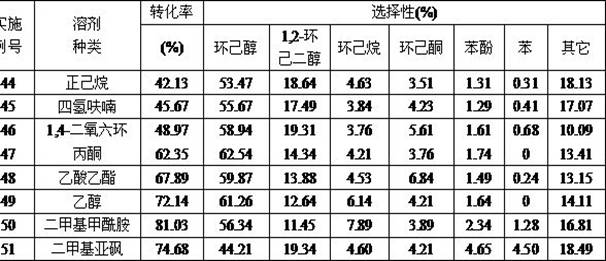

[0042] Embodiment 1: The hydrogenation device is a stainless steel high-pressure electric heating reactor of 20 milliliters. First, 1.2 g of guaiacol is added to 4.8 g of decahydronaphthalene, and a uniform mass fraction of 20% guaiacol is formed by using a magnet to stir for 30 min. Add 0.1 g of Catalyst A to the clocinol solution, quickly close the autoclave, and replace the air in the autoclave with hydrogen for 3-4 times, start stirring, adjust the pressure of the hydrogen gas introduced to 2.0 MPa, and raise the temperature to 200°C. After continuous reaction for 200 min, cool down to room temperature, release the pressure carefully, take out the product and weigh it, and take the upper liquid and centrifuge it to detect it with the internal standard method of gas chromatography. Ethylbenzene is used as the internal standard, and the conversion rate and See Table 1 for selectivity data.

Embodiment 2

[0043] Example 2: Catalyst B is selected, the reaction feeding and hydrogenolysis reaction conditions are the same as in Example 1, and the calculated conversion and selectivity data of related species are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com