A method for preparing odorless isododecane

An isomerized dodecane, odorless technology, applied in the direction of separation methods, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of combustion and explosion, loss of effective components, large consumption, etc., and achieve good adsorption selectivity, The effect of small solid waste output and low regeneration temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

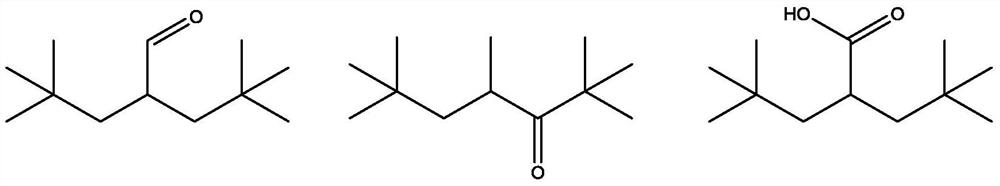

Problems solved by technology

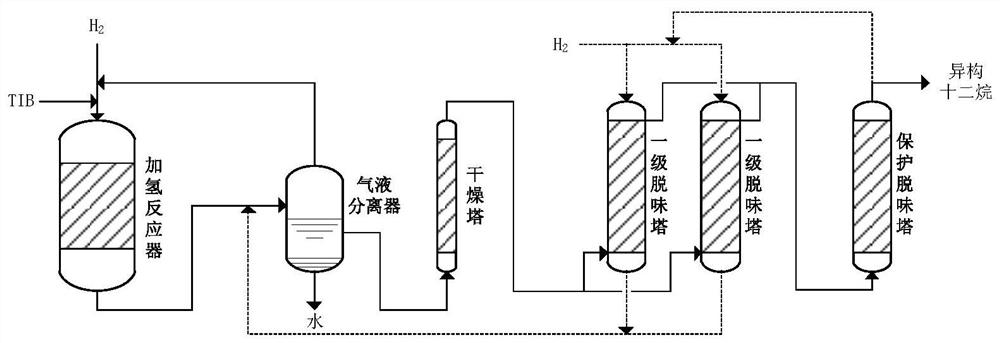

Method used

Image

Examples

Embodiment 1

[0030] Preparation of porogen: TIB and SO in a falling film sulfonator 3 The sulfonation reaction of TIB with SO 3 The molar ratio is 1:1.1, the sulfonation reaction temperature is 30°C, SO 3 The gas concentration is 5%; the sulfonated product is hydrolyzed with 20wt% NaOH solution at 135°C for 1.5 hours to obtain the sodium sulfonate of TIB.

[0031] Adsorbent preparation: hydrolyze ≥99.99% aluminum isopropoxide at 80°C, add nitric acid while stirring, wherein the molar ratio of aluminum isopropoxide, water and nitric acid is 1:100:0.2. After the solution turns into a transparent sol, add the sodium sulfonate porogen of TIB to it, and the molar ratio of sodium sulfonate to aluminum isopropoxide is 0.05:1. After stirring for 1 hour, put it into a polytetrafluoroethylene-lined autoclave, keep the temperature at 105°C for 24 hours, take it out, cool it and dry it, and then bake it at 500°C for 4 hours to obtain an average particle size of 0.1mm and an average pore size of 2nm....

Embodiment 2

[0037] Preparation of porogen: benzene and TIB with a molar ratio of 1.5:1 are placed in a reactor, and aluminum trichloride equivalent to 1 wt% of the substrate is added as a catalyst, and the reaction is completed at 85°C for 1.5 hours. After quenching by aluminum chloride, the benzene and TIB in the oil phase were removed by distillation, and the obtained dodecylbenzene was treated with SO in the falling film sulfonator. 3 Sulfonated, dodecylbenzene with SO 3 The molar ratio is 1:1.2, the sulfonation reaction temperature is 35°C, SO 3 The gas concentration is 5%; the sulfonated product is hydrolyzed with 20% KOH solution at 135° C. for 2 hours to obtain potassium benzenesulfonate of TIB.

[0038] Adsorbent preparation: The preparation process of the carrier is the same as in Example 1, and the porogen is changed to potassium benzenesulfonate of TIB. The molar ratio of potassium benzenesulfonate of TIB to aluminum isopropoxide is 0.045:1, and the average particle size is ob...

Embodiment 3

[0044] Preparation of porogen: TIB is mixed with synthesis gas (CO:H 2 =1:1) reaction, with 0.01wt% rhodium octanoate as catalyst, after reaction time 20h at temperature 150°C and pressure 15MPa, then switch the synthesis gas to hydrogen, hydrogenation at 150°C and 15MPa for 5h to obtain iso-containing A mixture of tridecyl alcohol and isomeric dodecane, and the isomeric dodecane is removed by rectification to obtain isotridecyl alcohol. In the reaction kettle, the isotridecyl alcohol prepared by TIB is used as the initiator, and 0.2% KOH is used as the catalyst to react with ethylene oxide whose molar mass is 3 times that of the isotridecyl alcohol at 0.5 MPa and 85°C. 5h, then aged at 120°C for 1 hour and then cooled to obtain isomeric tridecyl alcohol polyoxyethyl ether with an ethylene oxide addition number of 3.

[0045] Adsorbent preparation: the preparation process of the carrier is the same as in Example 1, and the porogen is changed to isomeric tridecyl alcohol polyo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com