A drug-loaded microsphere based on slow and controlled drug release method for preventing and controlling bacteria in bioethanol fermentation

A technology of drug-loaded microspheres and bioethanol is applied in the field of prevention and control of Saccharomyces cerevisiae fermentation and contamination, which can solve the problems of time-consuming and labor-intensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Embodiment 1: Activation of Lactobacillus plantarum

[0058] 1. Activation of Lactobacillus plantarum: Prepare 300mL MRS medium, take three 250mL Erlenmeyer flasks, fill each bottle with 100mL medium, and one bottle labeled "Activated MRS" is used to activate Lactobacillus plantarum ATCC8014. Add 0.75g agar and 1.5g agar respectively to the remaining 2 bottles to make a solid medium, which is reserved for the third step of antimicrobial drug activity determination. Put the aliquoted MRS medium into a high-temperature steam sterilizer, and sterilize it at 115°C for 20 minutes; after the sterilization is completed, take out the medium and cool it in an ultra-clean bench. Lactobacillus plantarum ATCC8014 was inoculated in the MRS medium marked as "activated", and placed in a constant temperature incubator at a constant temperature of 37 ° C for 14 hours of activation culture.

Embodiment 2

[0059] Embodiment 2: yeast activation

[0060] 2. Yeast activation: Prepare 300mL YPD medium, take three 250mL Erlenmeyer flasks, and fill each bottle with 100mL medium, one of which is marked as "activated YPD" for activating Saccharomyces cerevisiae S288c strain, and the other 2 bottles Add 0.75g agar and 1.5g agar respectively to make a solid medium, which is reserved for the third step of antimicrobial drug activity determination. Put the subpackaged YPD medium into a high-temperature steam sterilizer, and sterilize it at 115°C for 20 minutes; after the sterilization is completed, take out the medium and cool it in an ultra-clean bench. Saccharomyces cerevisiae S288c was inoculated in the YPD medium marked as "activated", placed in a constant temperature culture shaker and activated for 20 hours at a constant temperature of 30°C and 150 rpm.

Embodiment 3

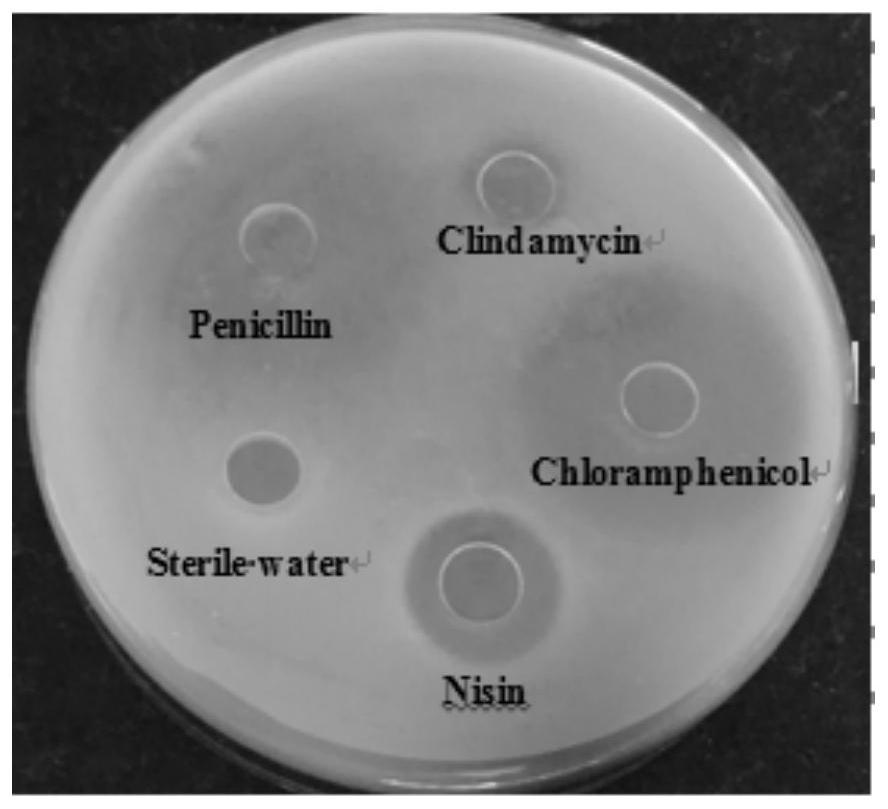

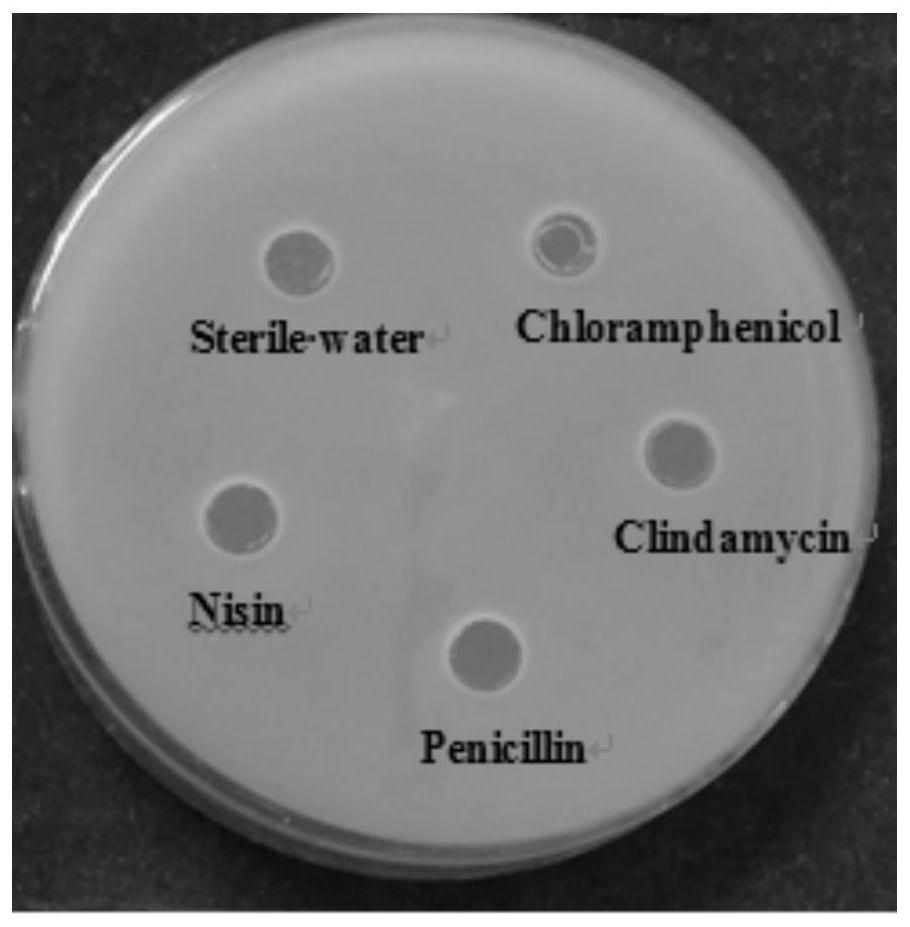

[0061] Embodiment 3: antibacterial drug antibacterial activity test

[0062] 3. Antibacterial drug antibacterial activity test: prepare 1 mg / mL of chloramphenicol, penicillin (ready to use), clindamycin and nisin, and use sterile water as a negative control. Pour MRS solid medium containing 1.8% (w / v) agar melted at medium-low heat into the sterilized plate in the ultra-clean bench, wait for it to dry, put a sterilized Oxford cup on it, and put 200 μL of the activated plant The bacteria liquid of Lactobacillus was mixed with 10 mL of MRS solid medium containing 0.75% (w / v) agar melted on medium-low heat and poured into the plate. After the upper culture medium is dry, remove the Oxford cup with sterilized tweezers, add 100 μL of 1 mg / mL chloramphenicol, penicillin, clindamycin, nisin, and sterile water to the removed Oxford cup to form in the small hole. Put the plate into a constant temperature incubator and incubate at a constant temperature of 37°C for 24 hours to observe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com