Preparation method of silicon substrate array with nanometer gaps being controllable and application thereof

A nano-gap and array technology, applied in the field of nano-gap array materials, can solve the problems of complex preparation method, small construction area, poor repeatability, etc., and achieve the effects of simple process, large construction area and clean surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

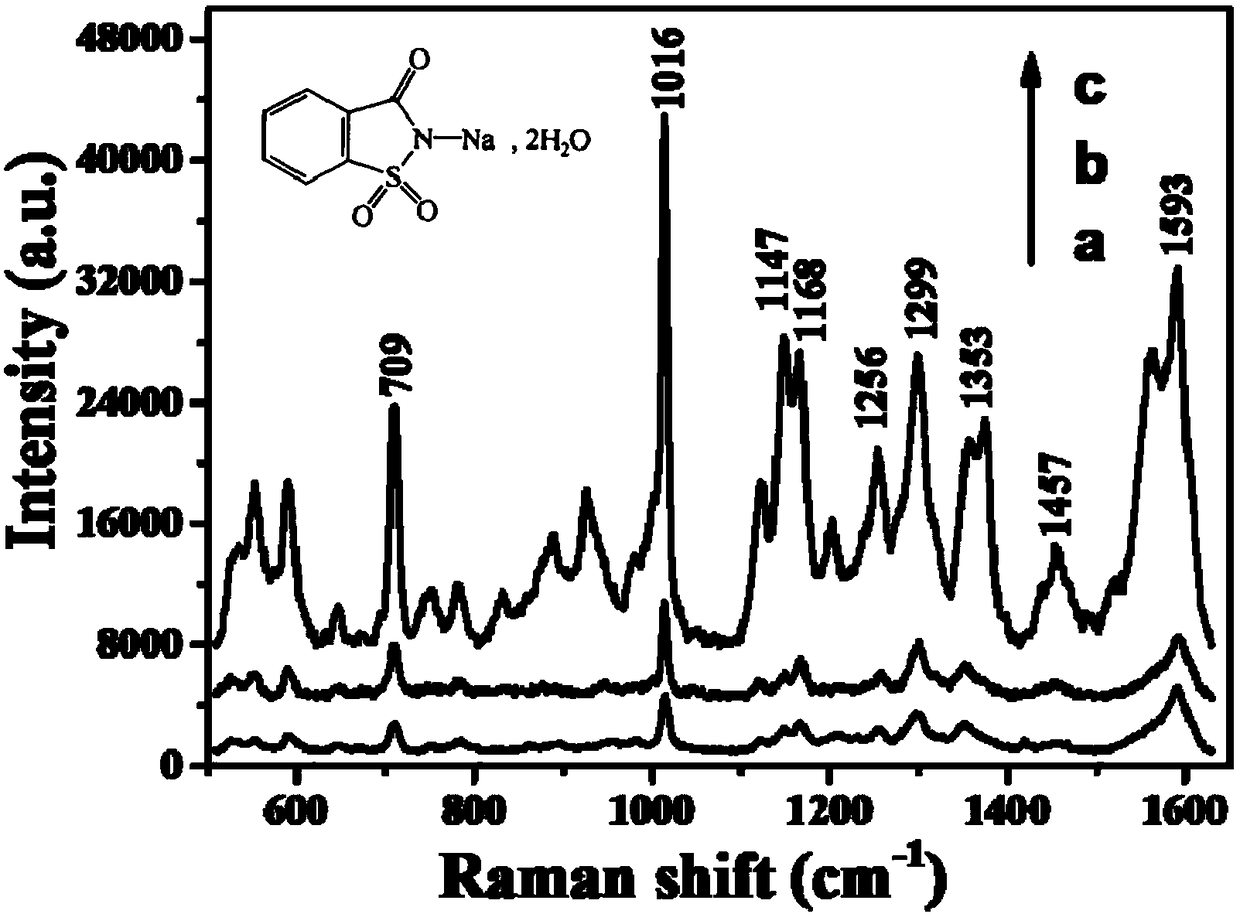

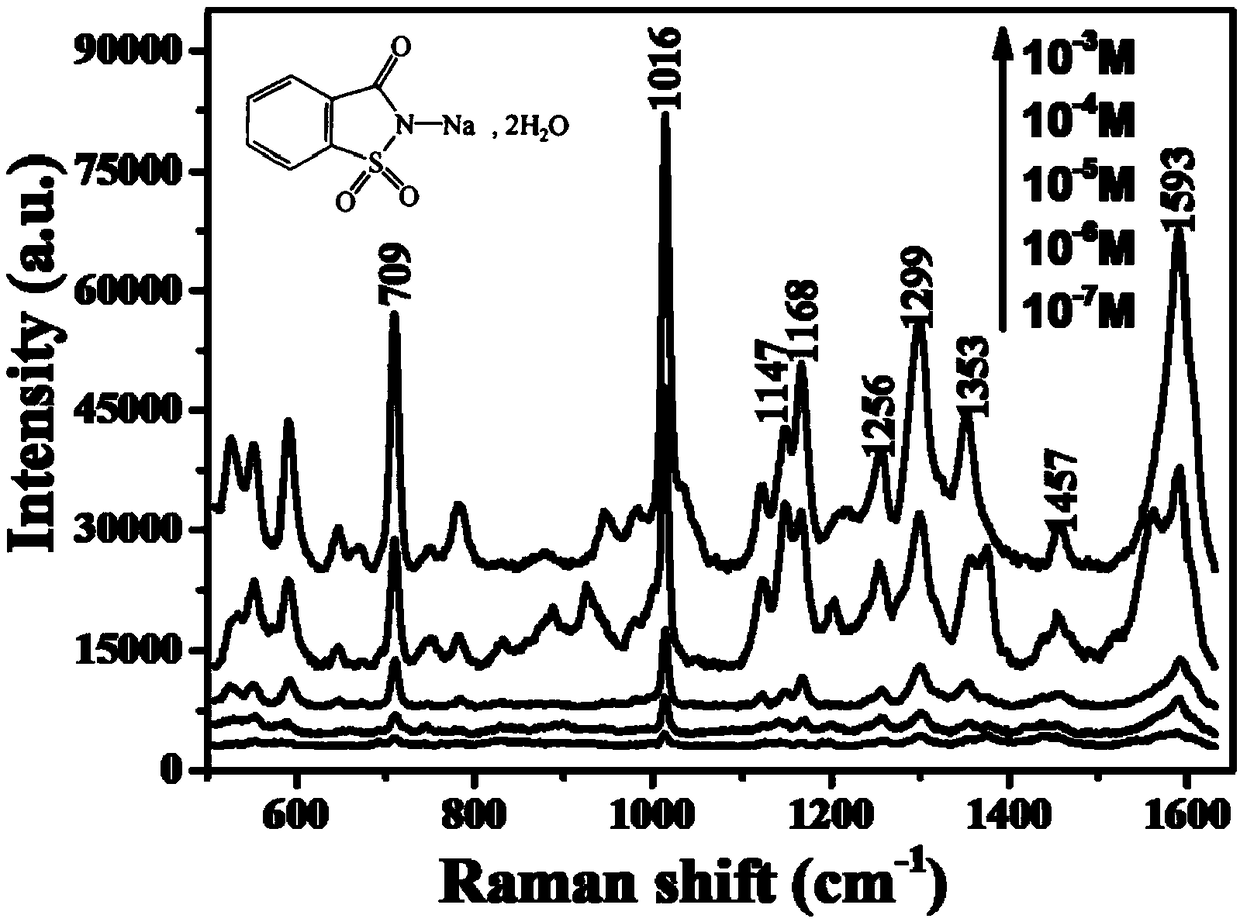

[0029] Such as Figure 4 As shown, a method for preparing a silicon-based array with controllable nano-gap includes the following steps:

[0030] Step A: Prepare a closely arranged single-layer polystyrene colloidal crystal array on the silicon wafer substrate to obtain a single-layer polystyrene colloidal crystal array on the silicon wafer substrate.

[0031] Step B: Use reactive ion etching to etch the single-layer polystyrene colloidal crystal array on the silicon wafer substrate, and remove the single-layer polystyrene colloidal crystal array on the silicon wafer substrate after the etching is completed, to obtain Conical silicon-based array.

[0032] Step C. Using the tapered silicon-based array as a template, a layer of gold film with a thickness of 10-50nm is deposited on the surface of the template by physical deposition method, and gold nanospheres are deposited on the top of the tapered silicon-based, through The deposition time is controlled to adjust the gap of the gold...

Embodiment approach

[0034] (1) The preparation of a closely arranged single-layer polystyrene colloidal crystal array on a silicon wafer substrate includes the following steps:

[0035] Step A1. Put the silicon wafer substrate into acetone, ethanol, the first mixed solution, and deionized water in sequence for ultrasonic cleaning, and then dry the cleaned silicon wafer substrate, and then place it in an ultraviolet ozone cleaning machine for 10 ~40min to obtain a silicon wafer substrate with a hydrophilic surface. Wherein, the first mixed solution is formed by mixing concentrated sulfuric acid with a mass concentration of 1.84 g / ml and hydrogen peroxide with a mass concentration of 1.1 g / ml in a volume ratio of 3:1.

[0036] Step A2. Put the silicon wafer substrate with hydrophilic surface into the ethanol diluent of polystyrene colloidal spheres, and use the gas-liquid interface self-assembly method to prepare tightly arranged monolayer polystyrene on the silicon wafer substrate Colloidal crystal ar...

Embodiment 1

[0047] Such as Figure 4 As shown, a method for preparing a silicon-based array with controllable nano-gap may specifically include the following steps:

[0048] Step a1. Put the silicon wafer substrate into acetone, ethanol, and the first mixed solution (the first mixed solution consists of concentrated sulfuric acid with a mass concentration of 1.84 g / ml and hydrogen peroxide with a mass concentration of 1.1 g / ml in a volume ratio of 3. :1), ultrasonic cleaning in deionized water, and then drying the cleaned silicon wafer substrate, and then placing it in an ultraviolet ozone cleaning machine and irradiating it for 10-40 minutes to obtain a silicon wafer with a hydrophilic surface Base.

[0049] Step b1. Take a polystyrene colloidal sphere suspension (2.5wt%) with a polystyrene colloidal sphere diameter of 120nm, mix it with ethanol in equal volume, and then perform ultrasonic oscillation treatment for 10-30 minutes to obtain a uniformly dispersed polystyrene Styrene colloidal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com