Highly dispersed noble metal-loaded ordered mesoporous tungsten oxide gas-sensitive material and preparation method thereof

A precious metal and tungsten oxide technology, which is applied to the analysis of materials, tungsten oxide/tungsten hydroxide, and gas mixture analysis. It can solve the problems of poor stability and dispersion of precious metal particles, complicated synthesis steps, and uncontrollable pore structure. Fast response and recovery time, suitable for scale-up production, simple method effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

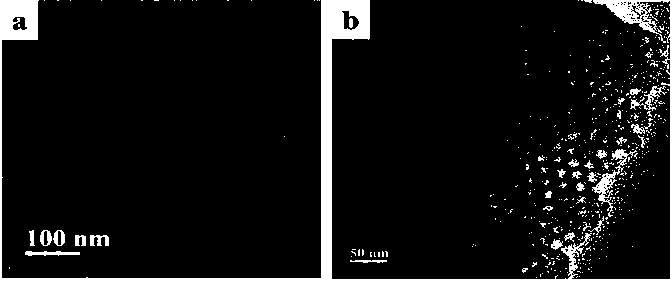

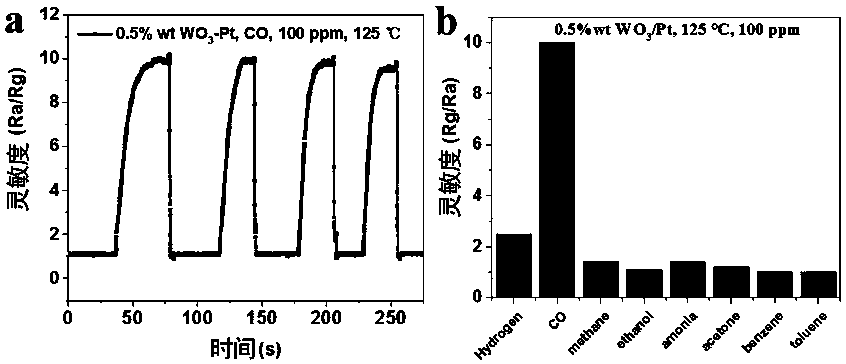

[0023] (1) Amphiphilic block copolymer polyethylene oxide- b - Polystyrene (PEO 108 - b -PS 210 , Mn= 26544 g mol -1 ) was dissolved in tetrahydrofuran (THF) solution, and stirred to obtain a homogeneous solution A (the polymer mass percentage was 2.0 wt%); anhydrous tungsten hexachloride (WCl 6 ) and acetylacetone (AcAc), stirred until the solid was completely dissolved to obtain a uniform solution B, mixed A and B and stirred for 2 h, and the solution turned dark green. Add 2.0 mg (1,5-cyclooctadiene) dimethyl platinum (II) (platinum source), and stir for 10 min. Wherein the mass ratio of block copolymer: tetrahydrofuran: ethanol: anhydrous tungsten hexachloride: acetylacetone: platinum source is 0.1:5:1:0.4:0.4:0.002;

[0024] (2) Transfer the solution to a petri dish with a diameter of 15 cm, volatilize at 25 °C for 1 h, and turn into a dark blue film, transfer the petri dish to a 40 °C oven for 48 h to further volatilize the solvent, and then transfer to 100 °C Afte...

Embodiment 2

[0027] (1) Amphiphilic block copolymer polyethylene oxide- b - Polystyrene (PEO 108 - b -PS 112 , Mn= 16689 g mol -1 ) dissolved in chloroform (CHCl 3 ) solution, stirred to obtain a homogeneous solution A (the polymer mass percentage is 2.0 wt%); anhydrous tungsten hexachloride (WCl 6 ) and acetylacetone (AcAc), stirred until the solid was completely dissolved to obtain a uniform solution B, mixed A and B and stirred for 2 h, and the solution turned dark green. Add (1,5-cyclooctadiene) dimethyl platinum (II) (platinum source) and triphenyl (phenylethynyl) lead (IV), and stir for 10 min. Wherein block copolymer: tetrahydrofuran: ethanol: anhydrous tungsten hexachloride: acetylacetone: platinum source: lead source mass ratio is 0.1:5:1:0.4:0.4:0.002:0.003;

[0028] (2) The solution was coated on a quartz substrate by spin-coating method, volatilized at 23 °C for 2 h, and turned into a dark blue film, which was transferred to an oven at 70 °C for 24 h to further volatilize...

Embodiment 3

[0031] (1) Amphiphilic block copolymer polyethylene oxide- b - Polystyrene (PEO 108 - b -PS 297 , Mn= 35975 g mol -1 ) dissolved in dichloromethane (CH 2 Cl 2 ) solution, stirred to obtain a homogeneous solution A (the polymer mass percentage is 2.0 wt%); anhydrous tungsten hexachloride (WCl 6 ) and acetylacetone (AcAc), stirred until the solid was completely dissolved to obtain a uniform solution B, mixed A and B and stirred for 2 h, and the solution turned dark green. Add (1,5-cyclooctadiene) dimethyl platinum (II) (platinum source), and stir for 10 min. Wherein block copolymer: tetrahydrofuran: ethanol: anhydrous tungsten hexachloride: acetylacetone: platinum source mass ratio is 0.1:5:1:0.4:0.4:0.02;

[0032] (2) Apply the solution on a quartz substrate by dip-coating method, volatilize at 25 °C for 1 h, and turn into a dark blue film, transfer it to a 40 °C oven for 24 h to further volatilize the solvent, and then transfer Cured at 100 °C for 24 h to obtain a brow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com