Multi-component spray reticule coating as well as preparation method and application thereof

A kind of marking paint, multi-component technology, applied in fireproof paint, reflective/signal paint, antifouling/underwater paint, etc., can solve the problem of easy peeling off of marking paint, low binding force, poor antifouling and self-cleaning performance, etc. problem, to achieve the effect of good ductility and mechanical strength, enhanced compactness, good self-cleaning and anti-fouling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

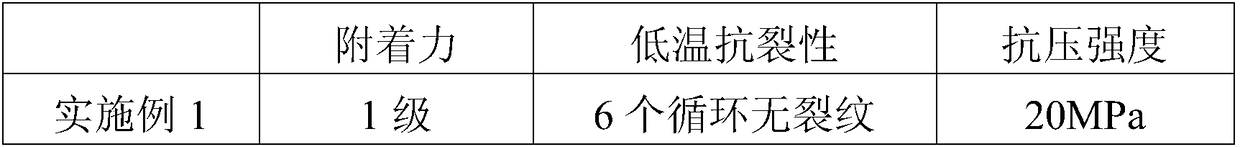

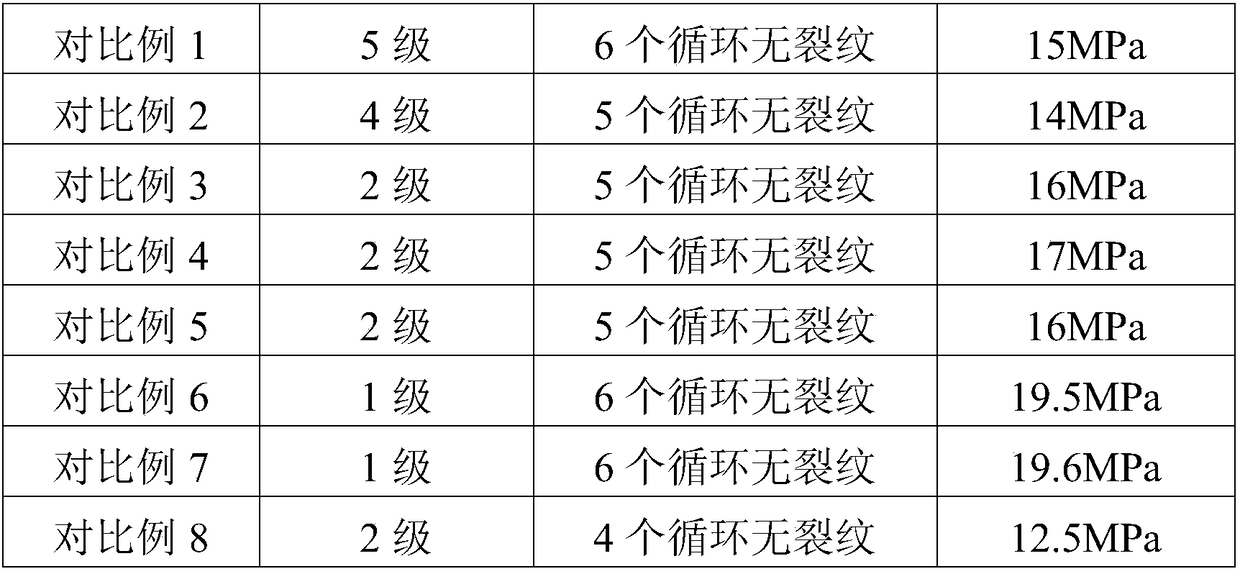

Examples

preparation example Construction

[0035] The modified glass microspheres adopted in the following examples are prepared by the following preparation method: specific operation steps:

[0036] 1) Prepare organic modifier solution: prepare organic modifier solvent with water and alcohol at a ratio of 1:8-10; then use organic acid to adjust the pH to acidic, and add 5-20% The coupling agent until transparent, then add 0.5-5% surfactant, then add 2-10% film-forming agent, heat up to 40-50°C, and stir at 500-4000 rpm for 0.5-2 hours;

[0037] 2) Modified glass beads: disperse the glass beads into the organic modification solution prepared in step 1), and stir at 500-4000 rpm for 1-3 hours at a temperature of 40-50°C;

[0038] 3) Removing the residual modifying agent: filtering the mixed solution of glass microbeads modified in step 2), washing the filtered microbeads with hot water, stirring for 1 to 5 hours and filtering;

[0039] 4) Drying: vacuum-dry the glass microspheres treated in step 3) at a temperature of...

Embodiment 1

[0042] A multi-component spraying marking paint, which is composed of A component, B component and solid particle material C component;

[0043] Among them, component A is prepared from the following components in parts by weight: 25 parts of epoxy resin, 10 parts of hydroxyl-terminated polybutadiene liquid rubber, 6 parts of adipic acid, 2,6-diisocyanatohexyl 14 parts of methyl ester, 12 parts of 1,6-hexamethylene diisocyanate, 0.09 parts of stannous octoate, 42 parts of polycaprolactone polyol, 12 parts of dichloromethane, 12 parts of urea-formaldehyde resin, 9 parts of lithium silicate, ethylene glycol 5 parts of alcohol butyl ether;

[0044] Component B is prepared from the following components in parts by weight: 70 parts of self-crosslinking elastic acrylic resin emulsion, 6 parts of polydimethylsiloxane, 14 parts of diethyltriamine, and 15 parts of dichloromethane;

[0045] Component C is composed of the following components in parts by weight: 15 parts of nano silicon d...

Embodiment 2

[0056] A multi-component spraying marking paint, which is composed of A component, B component and solid particle material C component;

[0057] Among them, component A is prepared from the following components in parts by weight: 20 parts of epoxy resin, 8 parts of hydroxyl-terminated polybutadiene liquid rubber, 5 parts of adipic acid, 2,6-diisocyanatohexyl 12 parts of methyl ester, 10 parts of 1,6-hexamethylene diisocyanate, 0.08 parts of stannous octoate, 40 parts of polycaprolactone polyol, 10 parts of methylene chloride, 10 parts of urea-formaldehyde resin, 8 parts of lithium silicate, ethylene glycol 5 parts of alcohol butyl ether;

[0058] Component B is prepared from the following components in parts by weight: 60 parts of self-crosslinking elastic acrylic resin emulsion, 5 parts of polydimethylsiloxane, 12 parts of diethyltriamine, and 12 parts of dichloromethane;

[0059] Component C is composed of the following components in parts by weight: 10 parts of nano silic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com