Low-cost graphene quantum dot preparation method

A low-cost technology of graphene quantum dots, applied in graphene, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of serious pollution and production costs, and achieve good monodispersity, environmental friendliness, and non-toxic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

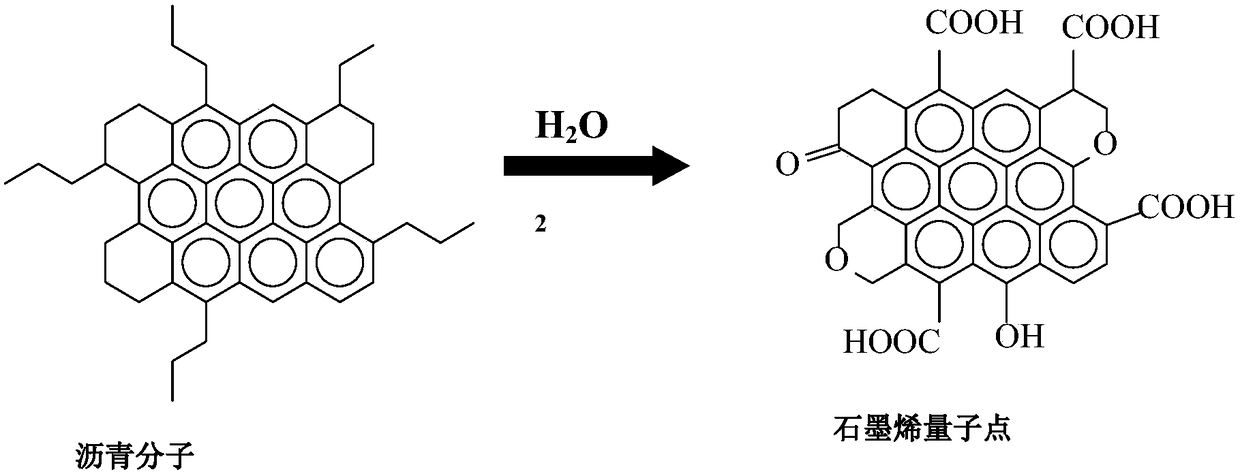

[0049] Take by weighing 0.2g coal tar pitch (it should be noted that it must be coal tar pitch, and other pitches are invalid) at room temperature and put it into a 200ml flask, add 200ml mass concentration of 15% hydrogen peroxide solution, then put the flask Put it into a 500w ultrasonic cleaner for 2h to obtain a dispersion of coal tar pitch; transfer it to a 500ml round bottom flask, reflux for 2h under heating with a heating mantle (liquid temperature is 110°C), cool to room temperature, and obtain GQDs -1 crude product; filter the obtained crude product with a 0.22 μm microporous membrane to obtain a GQDs-1 aqueous solution, which is freeze-dried to obtain a brown solid GQDs-1.

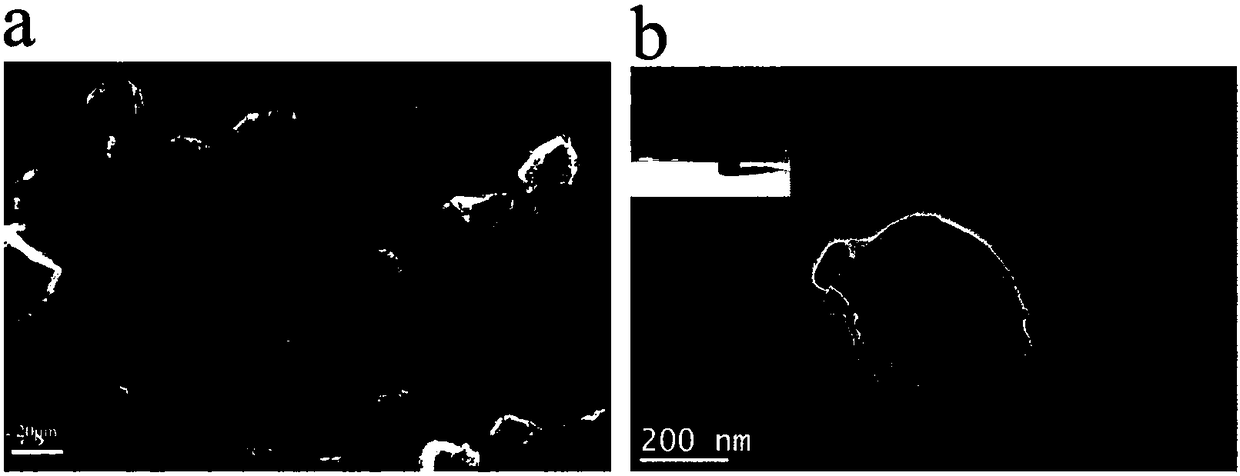

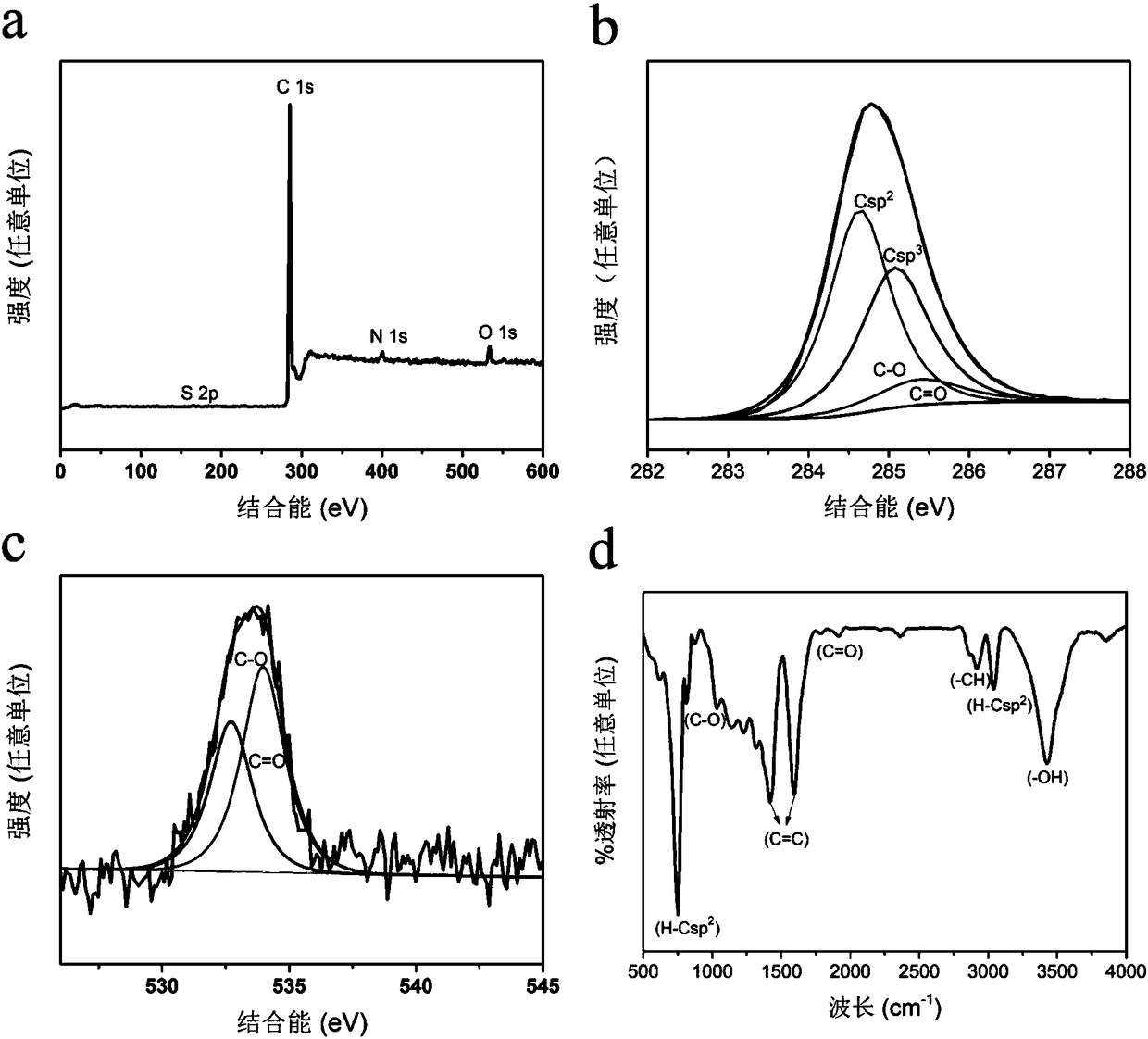

[0050] The coal tar pitch that above-mentioned method uses is preferably the coal tar pitch that boiling point is more than 360 ℃; SEM ( figure 2 a) shows that the coal tar pitch used exhibits irregular size and shape, ranging from 1 μm to 20 μm in diameter; TEM ( figure 2 b) shows that the c...

Embodiment 2

[0054] Weigh 0.2g of coal tar pitch at room temperature and put it into a 200ml flask, add 200ml of hydrogen peroxide solution with a mass concentration of 30%, then put the flask into a 500w ultrasonic cleaner for 2 hours to obtain a dispersion of coal tar pitch It is transferred to a 500ml round-bottomed flask, refluxed for 2h (liquid temperature is 110° C.) under the heating of a heating mantle, and cooled to room temperature to obtain the crude product of GQDs-2; Filtration was performed to obtain an aqueous solution of GQDs-2, which was freeze-dried to obtain GQDs-2 as a pale yellow solid.

[0055] The above-mentioned GQDs-2 aqueous solution is transparent and colorless under natural light irradiation, and is blue under ultraviolet light; TEM ( Figure 9 a) and size distribution histogram ( Figure 9 b) shows that the as-prepared GQDs-2 are monodisperse with uniform size and shape, and its diameter is 2.3±0.7nm; HRTEM( Figure 9 c) shows that the as-prepared GQDs-2 is h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com