A kind of microfoam flame-retardant polyurethane material and preparation method thereof

A polyurethane material and micro-foaming technology, which is applied in the field of polyurethane materials, can solve the problems of poor aging resistance, general wear resistance, and poor hydrolysis resistance, and achieve excellent aging resistance, good anti-slip performance, and good wear resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] The preparation method of the above-mentioned microfoaming flame-retardant polyurethane material comprises the following steps:

[0053] 1) Add polycarbonate diol and filler to the reaction kettle, vacuumize, and stir at 100-120°C for 1-2 hours;

[0054] 2) Cool down to 40-50°C, add isocyanate, react at 70-90°C for 1-2 hours, then add pigment, halogen-free flame retardant, flame retardant synergist, chemical foaming agent, physical foaming agent, antioxidant , an ultraviolet absorber and an antifungal and antibacterial agent, and stirred at 40-50° C. for 20-30 minutes to obtain a micro-foaming flame-retardant polyurethane material.

Embodiment 1

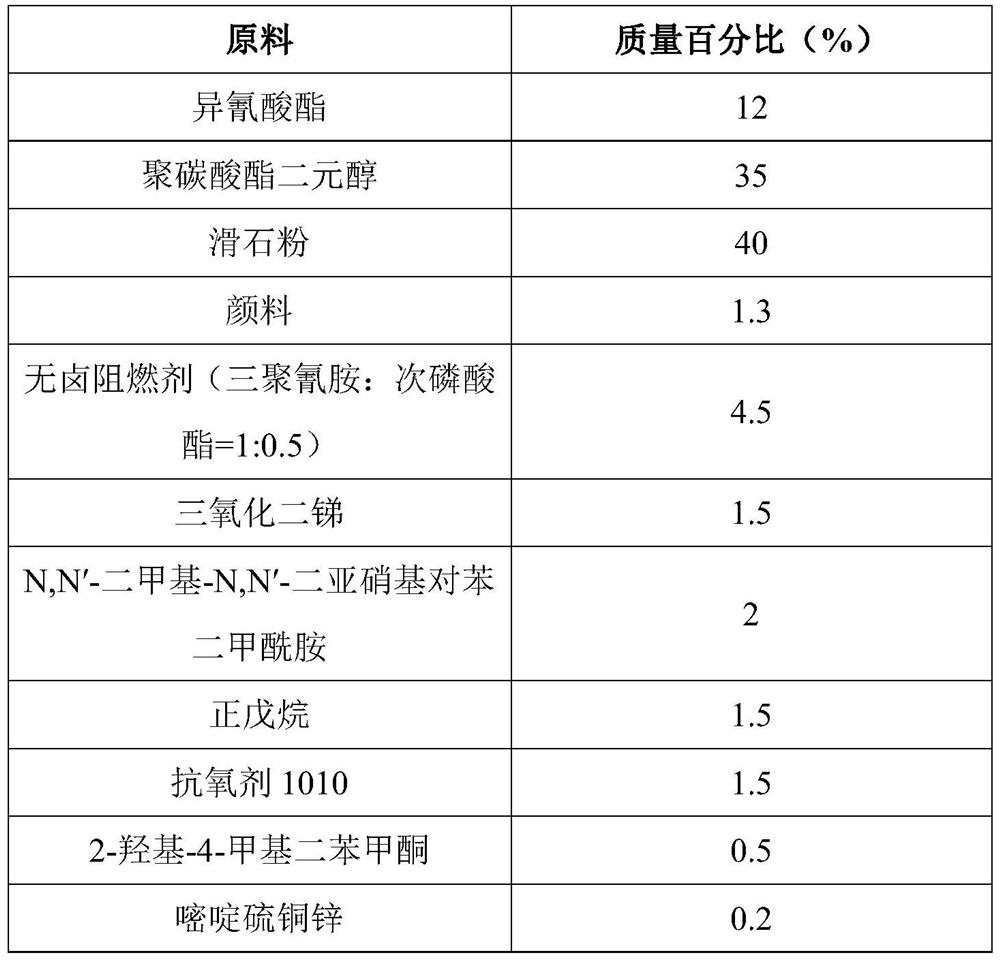

[0057] A kind of microfoam flame-retardant polyurethane material, its raw material composition is as shown in the following table:

[0058] Table 1 The raw material composition table of a kind of microfoam flame-retardant polyurethane material

[0059]

[0060] The preparation method of the above-mentioned microfoaming flame-retardant polyurethane material comprises the following steps:

[0061] 1) Add polycarbonate diol and talcum powder to the reaction kettle, vacuumize, and stir at 120°C for 1.5h;

[0062] 2) Cool down to 40°C, add isocyanate, react at 70°C for 2 hours, then add pigment, melamine, hypophosphite, antimony trioxide, N,N'-dimethyl-N,N'-dinitroso p-phenylene Diformamide, n-pentane, antioxidant 1010, 2-hydroxy-4-methylbenzophenone, and pyrimidinesulfur copper zinc were stirred at 45° C. for 30 minutes to obtain a microfoaming flame-retardant polyurethane material.

Embodiment 2

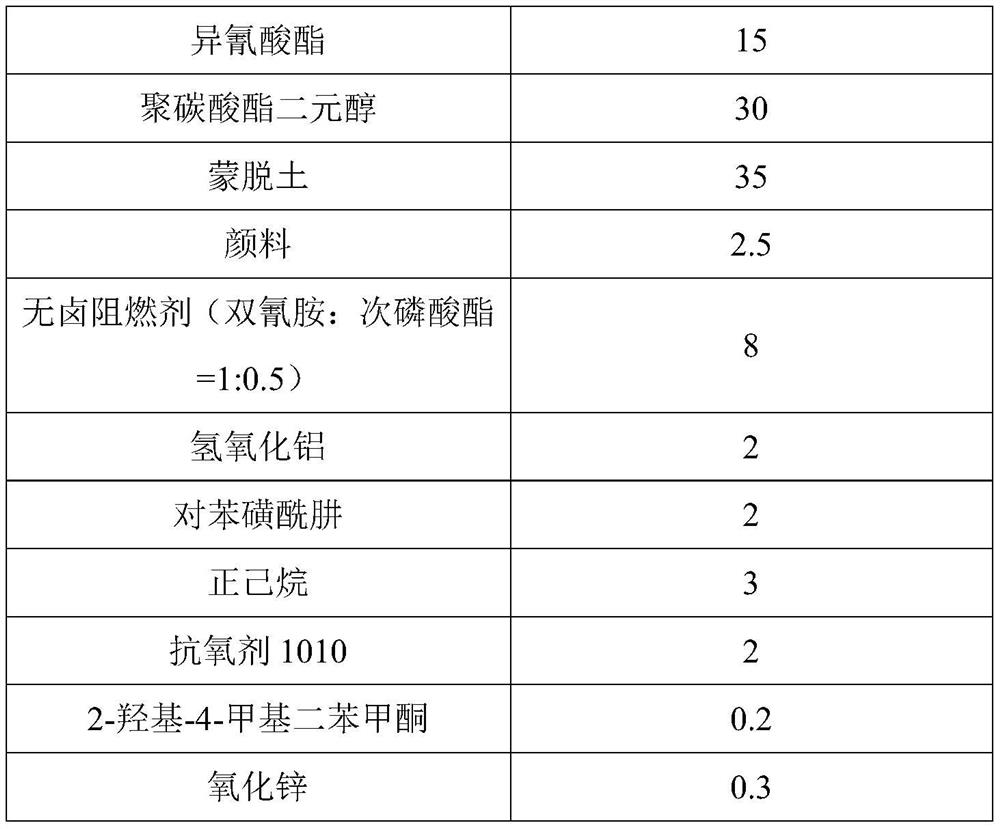

[0064] A kind of microfoam flame-retardant polyurethane material, its raw material composition is as shown in the following table:

[0065] Table 2 The raw material composition table of a kind of microfoam flame-retardant polyurethane material

[0066]

[0067]

[0068] The preparation method of the above-mentioned microfoaming flame-retardant polyurethane material comprises the following steps:

[0069] 1) Add polycarbonate diol and montmorillonite to the reaction kettle, vacuumize, and stir at 120°C for 2 hours;

[0070] 2) Cool down to 40°C, add isocyanate, react at 80°C for 2 hours, then add pigment, dicyandiamide, hypophosphite, aluminum hydroxide, p-benzenesulfonyl hydrazide, n-hexane, antioxidant 1010, 2-hydroxyl-4 - methyl benzophenone and zinc oxide, stirred at 40° C. for 30 minutes to obtain a microfoaming flame-retardant polyurethane material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| micropore | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com