Preparation method of HA/MoS2 biological composite coating, with photocatalytic activity, on surface of titanium alloy

A technology of photocatalytic activity and composite coating, which is applied in the interdisciplinary field of material science and biomaterials, can solve the problems of bacterial resistance, weak binding force, and functional effects, and achieve the effect of convenient acquisition and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] A photocatalytically active HA / MoS on the surface of titanium alloy 2 The preparation method of biological composite coating, the steps include as follows:

[0023] S1. Combine HA and MoS 2 Powder mixing and formulation of HA / MoS at a concentration of 1-200mg / mL 2 solution, ultrasonication, and then drop the obtained mixed solution onto the surface of the substrate, and after drying, the surface of the substrate with HA / MoS 2 Pre-coated samples;

[0024] Preferably, in step S1, HA and MoS 2 The mass ratio is 1-100:1-100;

[0025] Preferably, in step S1, ultrasonication is performed in an ultrasonic machine above 500W for 0.5-2h;

[0026] Preferably, in step S1, the volume of the mixed solution dripped onto the surface of the substrate is 10-100uL;

[0027] Preferably, in step S1, the specific method of drying is: place the substrate with the mixed solution dripped on the surface in an oven, and dry it at 25-65°C for 0.3-3h;

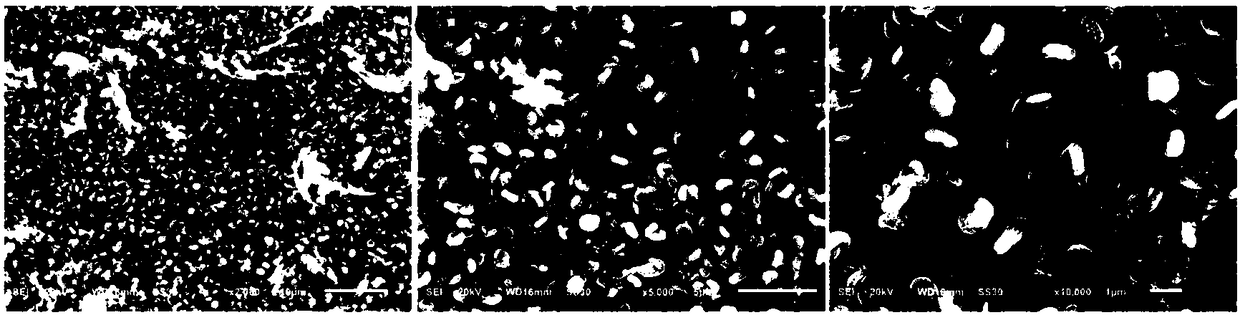

[0028] S2. Laser cladding treatment i...

Embodiment 1

[0036] A photocatalytically active HA / MoS on the surface of titanium alloy 2 The preparation method of biological composite coating, the steps include as follows:

[0037] S1. Mix 5mg of HA powder and 5mg of MoS 2 Mix the powders and prepare 1ml of HA / MoS with a concentration of 10mg / mL with deionized water 2 Suspension (50% MoS 2 ), put the obtained suspension into a 600W power ultrasonic instrument for 1h, and then use a pipette to draw 50uL of HA / MoS 2 The suspension was added dropwise to the surface of Ti6Al4V, put into an oven, and dried at 60 °C for 1 h, so that the surface of Ti6Al4V was coated with HA / MoS 2 pre-coating;

[0038] S2. The sample obtained in step S1 is placed on a two-dimensional laser platform, and the laser current is set to 100A, the frequency is 20Hz, and the pulse width is 2ms, and laser cladding is performed;

[0039] S3, due to the laser treatment in S2, there is a part of MoS on the surface of Ti6Al4V 2 oxidized to MoO 3-X , therefore, put ...

Embodiment 2

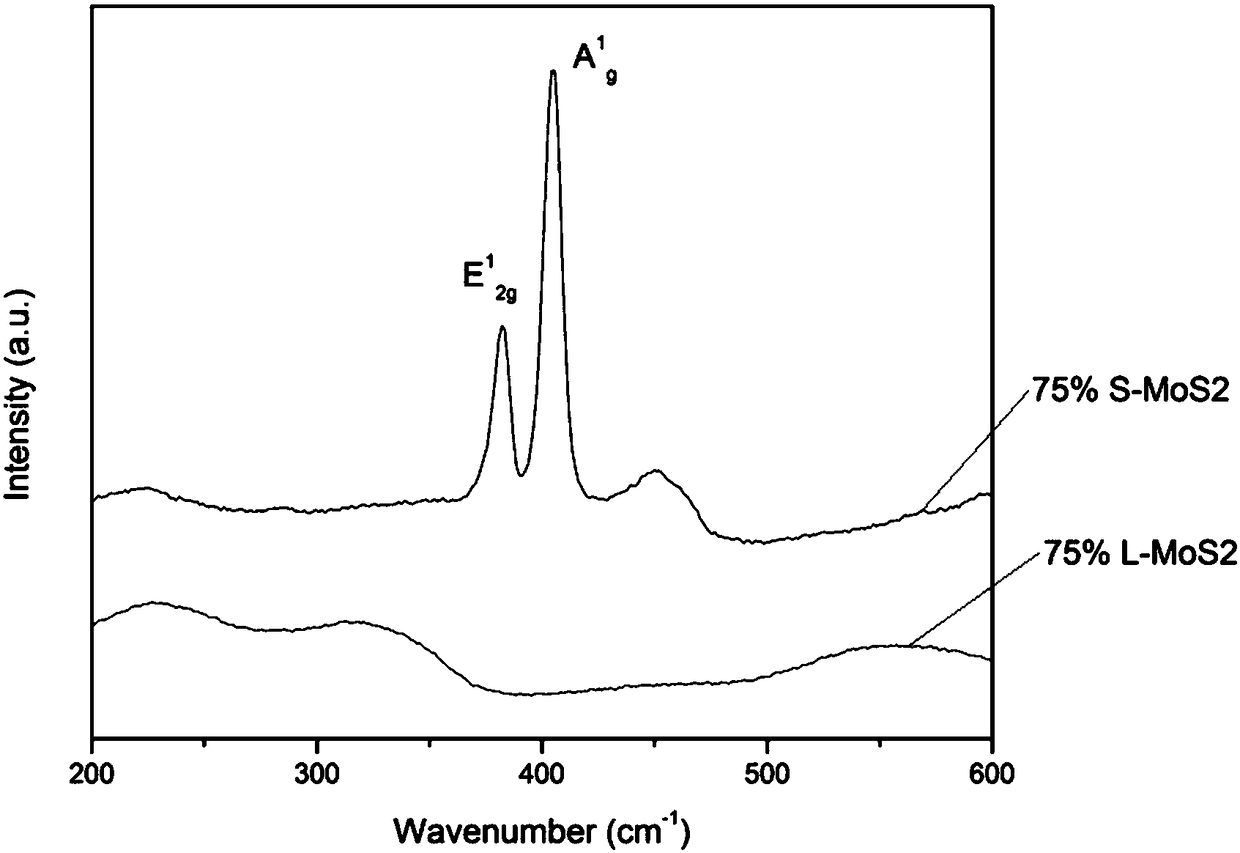

[0042] This embodiment provides a preparation method before and after vulcanization of the prefabricated coating in proportion, and the steps include as follows:

[0043] S1, 2.5mg of HA powder and 7.5mg of MoS 2 Mix the powders and prepare 1ml of HA / MoS with a concentration of 10mg / mL with deionized water 2 Suspension (75% MoS 2 ), put the obtained suspension into a 600W power ultrasonic instrument for 1h, and then use a pipette to draw 50uL of HA / MoS 2 The suspension was added dropwise to the surface of Ti6Al4V, put into an oven, and dried at 60 °C for 1 h, so that the surface of Ti6Al4V was coated with HA / MoS 2 pre-coating;

[0044] S2. Place the sample obtained in step S1 on a two-dimensional laser platform, and set the laser current to 100A, frequency to 20Hz, and pulse width to 2ms to perform laser cladding treatment, and then separate a part of the sample and mark it as 75% L-MoS 2 ;

[0045] S3, due to the laser treatment in S2, there is a part of MoS on the surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com