Albendazole nanopowder and preparation method thereof

A technology of albendazole and nano-powder, which is applied in the field of albendazole nano-powder and its preparation, can solve the problems of low bioavailability and poor absorbability, and achieve high bioavailability, improved solubility and absorbability, The process is stable and feasible

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

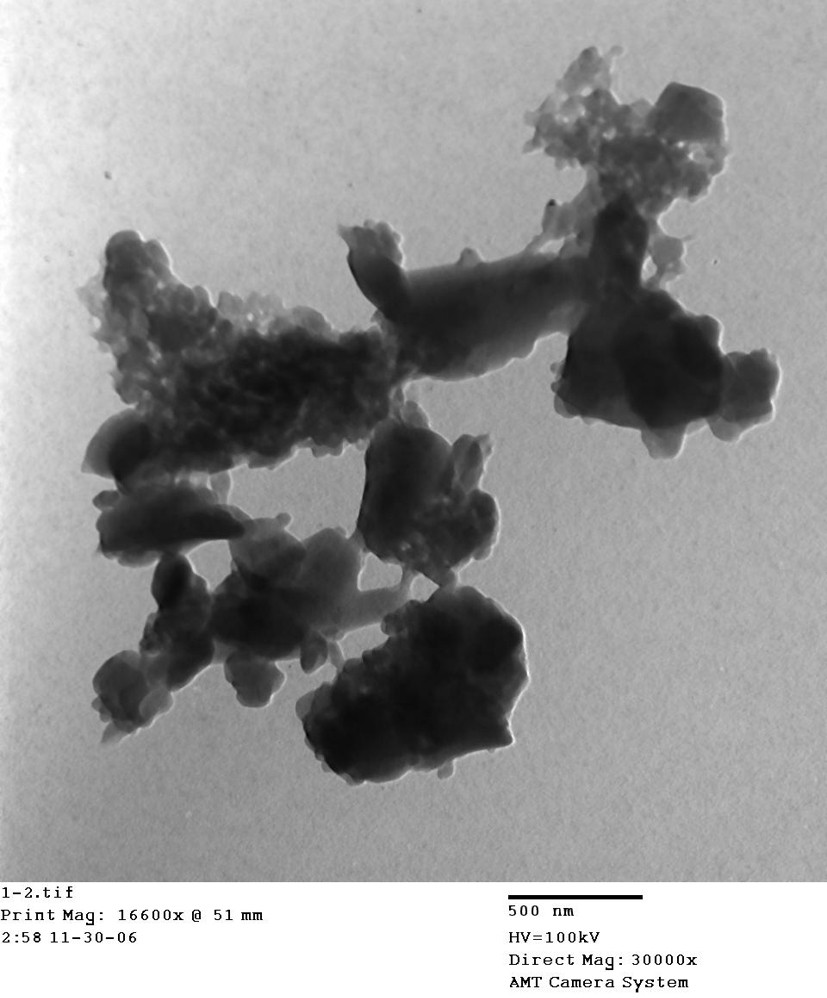

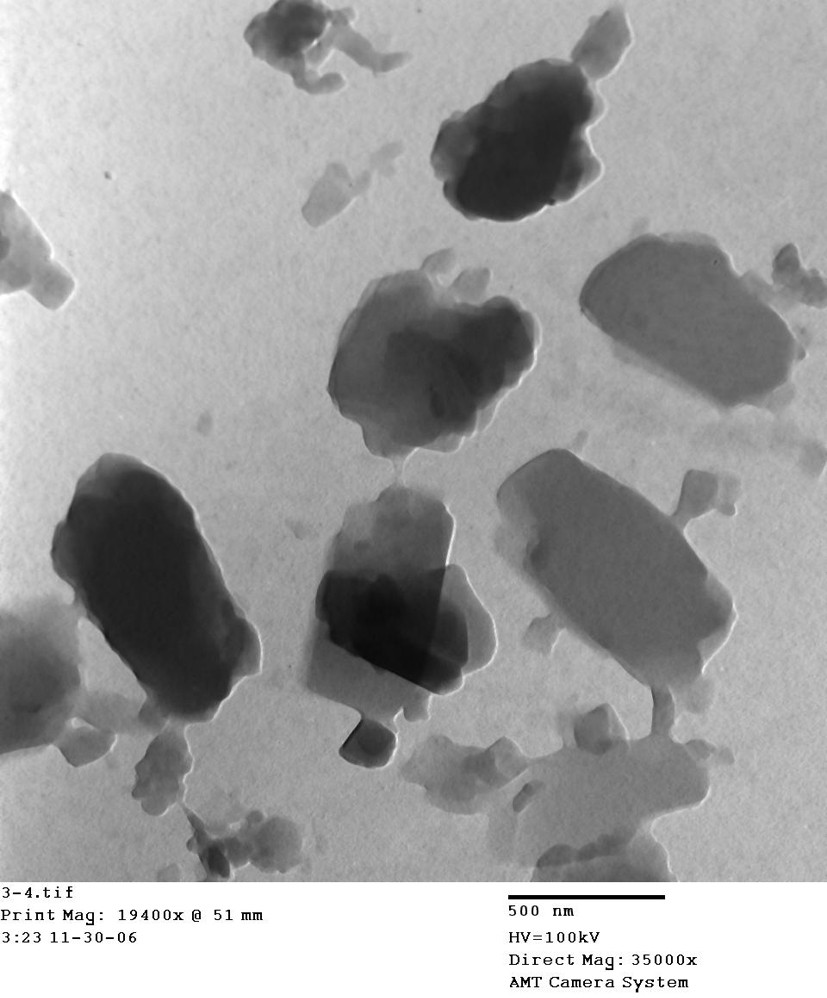

[0051] Embodiment 1: The albendazole nano-powder is obtained according to the following preparation method: the first step, the albendazole raw material is sieved after ball milling to obtain the albendazole ball milling raw material; the second step, the albendazole The azole ball mill raw material is mixed with an aqueous solution containing an appropriate amount of dispersant to obtain a raw material suspension of albendazole; in the third step, the raw material suspension of albendazole is subjected to high-speed shearing to obtain an initial suspension of albendazole; The fourth step is to obtain the albendazole nanosuspension after high-pressure homogenization of the albendazole initial suspension; the fifth step is to add the required amount of drying protection agent to the albendazole nanosuspension , and then dried to obtain albendazole nano-powder.

[0052] In this embodiment, the process of preparing albendazole (ABZ) nano-powder by ball milling, high-speed shearin...

Embodiment 2

[0055] Embodiment 2: As the optimization of above-mentioned embodiment, the mass ratio of albendazole raw material and dispersant is 1:2 to 4:1, and described dispersant is Tween 80, poloxamer 407, poloxamer 188, one of sodium lauryl sulfate, macrogol 1000 natural vitamin E succinate, polyethylene glycol 15-hydroxystearate, polyoxyethylene hydrogenated castor oil 40; addition of dry protection agent Add 5 grams to 20 grams of desiccation protection agent according to 100 milliliters of albendazole nanosuspension, and described desiccation protection agent is maltodextrin, mannitol, inositol, sorbitol, xylitol, lactitol, maltose Alcohol, alanine, glycine, L-histidine, lactose, sucrose, fructose, inulin, trehalose, maltose, hydroxypropyl-β-cyclodextrin.

Embodiment 3

[0056] Embodiment 3: As the optimization of the above-mentioned embodiment, the ball milling time is 4h to 12h, the ball milling temperature is less than 30°C, and the sieve is 200 mesh to 300 mesh; the albendazole in the albendazole raw material suspension The mass percentage is 0.5% to 2%; the speed of high-speed shearing is 3500r / min to 24000r / min, the shearing time is 5min to 20min, the shearing temperature is 0°C to 60°C; the temperature of high pressure homogenization is 0°C to 60°C, the pressure of high-pressure homogenization is 10000Psi to 30000Psi, and the number of high-pressure homogenization cycles is 5 to 35 times; the drying is normal pressure drying, reduced pressure drying, spray drying or freeze drying.

[0057] In this embodiment, a high-energy nano ball mill is used to ball mill the raw material of albendazole.

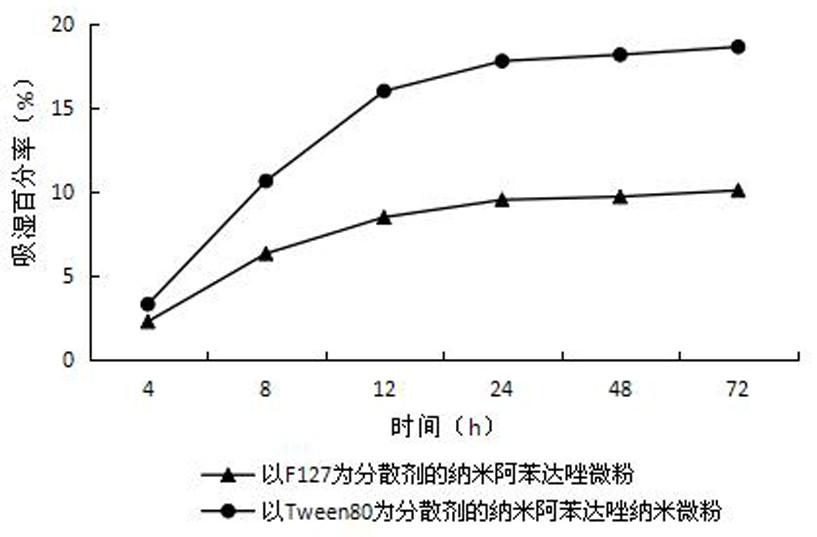

[0058] Compared with other drying methods (freeze drying, normal pressure drying, and reduced pressure drying), the ABZ nanopowder prepared by the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com