Immobilized liposome capillary monolithic column preparation method and application

A capillary monolithic column and liposome technology, applied in the field of separation and analysis, can solve the problems of unfavorable compound separation, substance-biofilm interaction, insignificant difference in retention behavior, limited increase range, etc., and achieve good separation ability and long life , reduce the effect of adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Preparation of liposomes.

[0031] 1. Prepare 4-hydroxyethylpiperazineethanesulfonic acid (HEPES) buffer

[0032] Accurately weigh 1.4894g of HEPES, add about 220mL of water to dissolve completely, adjust the pH to 7.40 with 1mol / L NaOH, add water to make up to 250mL, and obtain 25mmol / L HEPES buffer.

[0033] 2. Preparation of liposomes

[0034] (1) Accurately weigh 28.804 mg of phosphatidylcholine, dissolve it with 17 mL of chloroform:methanol solution (2:1, v / v), transfer it to a round-bottomed flask and evaporate under reduced pressure at 35°C until Form a uniformly dispersed film and dry it in vacuum for 12-16 hours to completely evaporate the residual organic solvent.

[0035] (2) Add about 7.6 mL of the above-prepared HEPES buffer solution into the flask, vortex to dissolve the film completely, and then form a multilamellar liposome solution. Using a cell ultrasonic breaker (200W; working time 3s; interval time 4s; ultrasonic frequency 99 times), the multi-cha...

Embodiment 2

[0038] Preparation of the immobilized liposome capillary monolithic column (the pressure applied to flush the capillary below is 50 psi).

[0039] 1. Take a new capillary and wash it with methanol for 30 minutes, 1 mol / L NaOH for 1 hour, 1 mol / L HCl for 30 minutes, and double distilled water until the effluent is neutral. 2 Dry under air at 120°C for 2 hours, and seal both ends with silicon rubber for later use.

[0040] 2. Weigh 50mg polyethylene glycol and 20mg urea, dissolve it with 500μL 0.01mol / L acetic acid solution, then slowly add 200μL tetramethoxysilane dropwise, stir vigorously in an ice-water bath, and inject it after the solution becomes a uniform sol state into the capillary; after reacting at 40°C for 12-16h, heat the capillary column at 120°C for 3h to expand the pores; then wash the capillary with methanol and water in sequence, 2 After drying at 50°C under atmosphere for 6h, it was raised from 50°C to 180°C at a rate of 2°C / min and kept for 1h, and finally h...

Embodiment 3

[0044] Performance testing of capillary monolithic columns of immobilized liposomes.

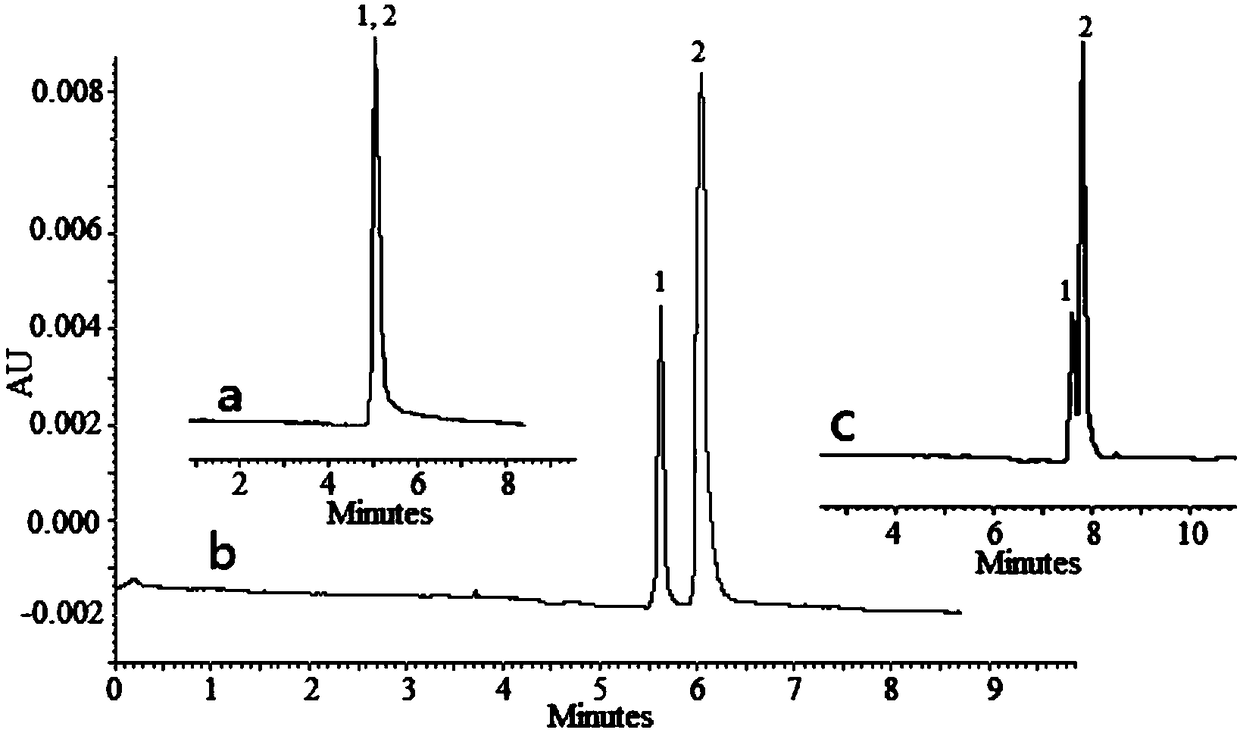

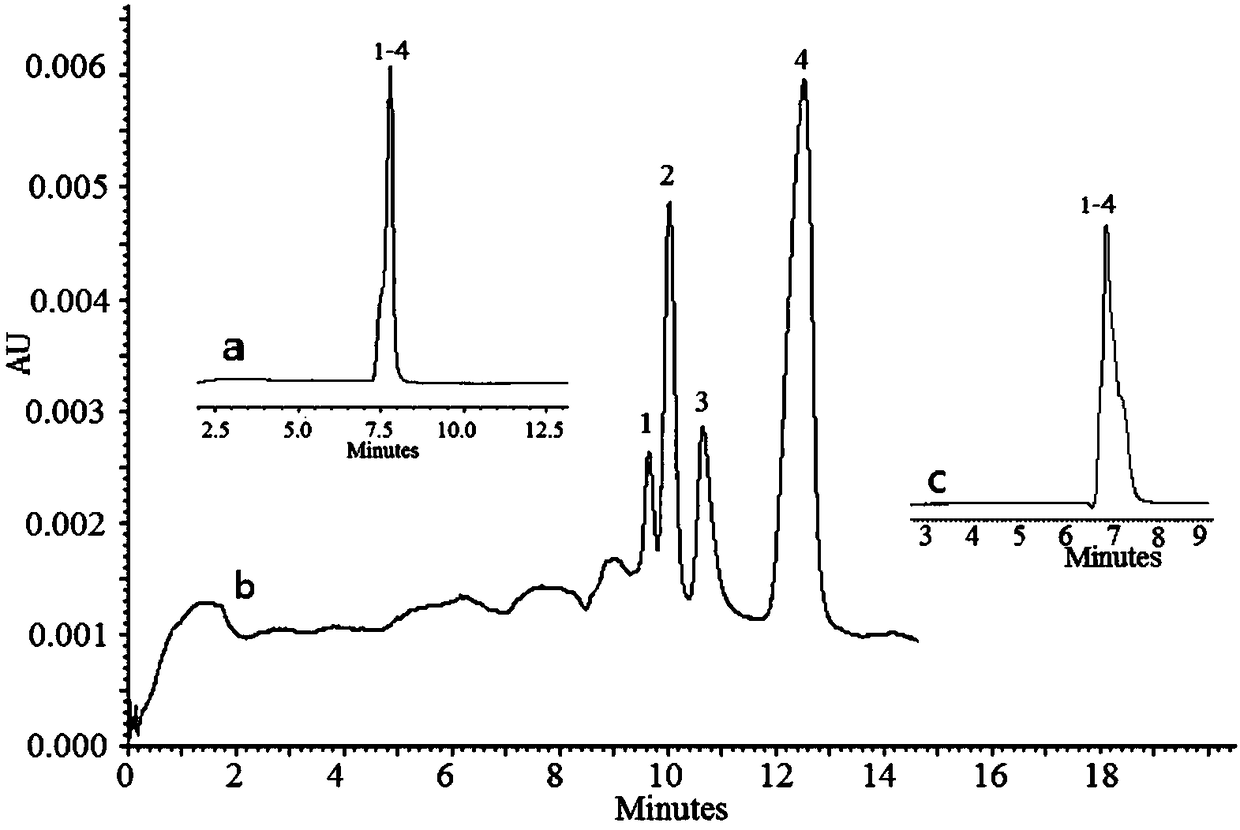

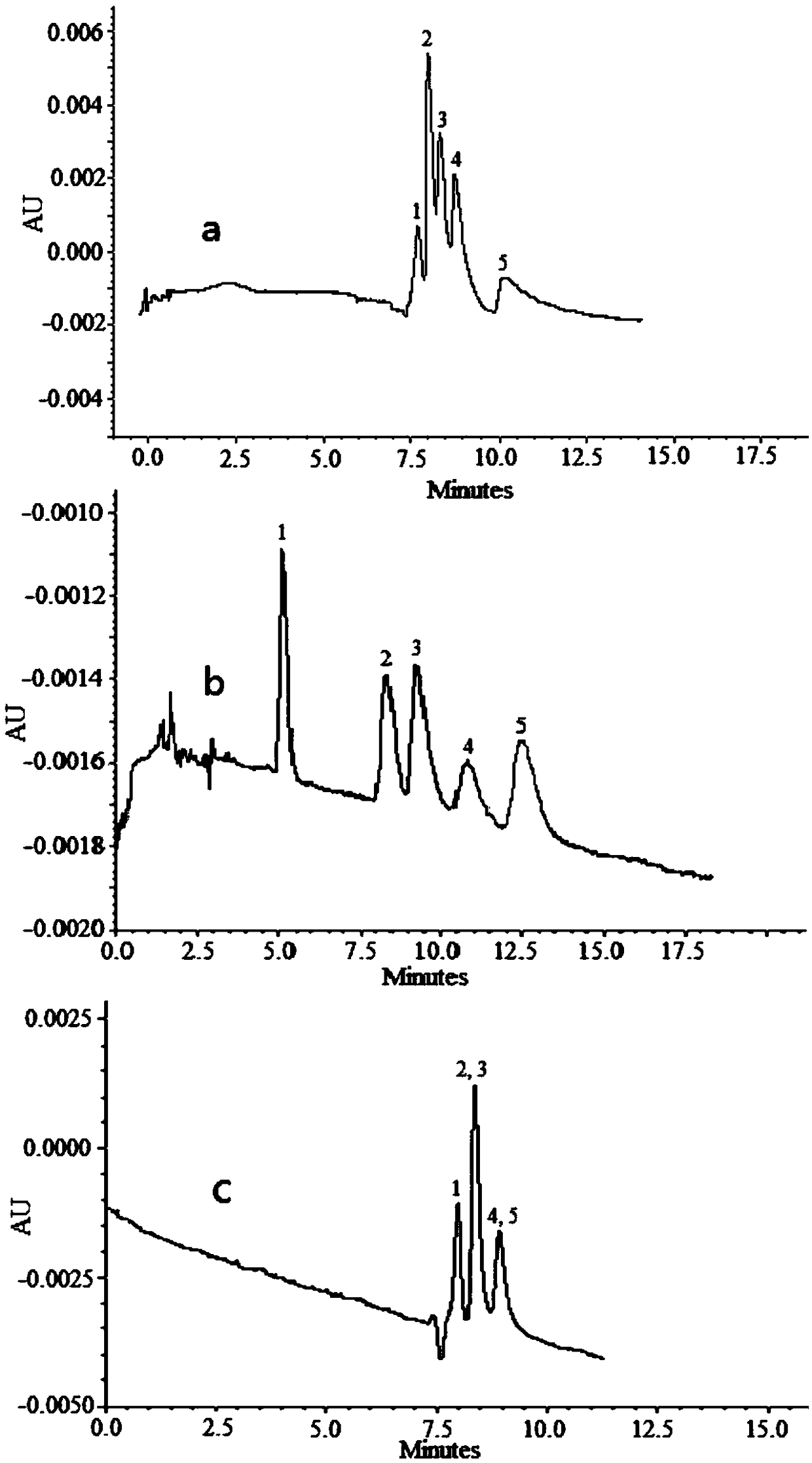

[0045] Electrochromatographic separation conditions: the total length of the immobilized liposome capillary monolithic column is 40.2cm, of which the effective length is 30cm; the electrophoresis buffer is 20mM phosphate buffer with pH 7.4; the sample injection condition is 3s under 5kV; the column temperature The temperature is 20°C, and the separation voltage is 20kV; when separating, add 50psi pressure at both ends of the capillary to prevent the generation of air bubbles. Thiourea neutral compound was used as a sample to determine electroosmotic flow (EOF).

[0046] Intra-day stability test: In the same immobilized liposome capillary monolithic column, the thiourea sample was repeatedly injected 30 times, and the relative standard deviation (RSD) of the measured EOF was 2.61% (n=30). The results showed that the prepared immobilized liposome capillary monolith column had good daily stabi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com