Bismuth vanadate photo-anode film and preparation method thereof

A bismuth vanadate, photoanode technology, applied in chemical instruments and methods, electrodes, vanadium compounds, etc., can solve the problems of slow charge separation/transportation, low charge mobility, poor oxidation kinetics, etc., and achieve good photoelectric catalytic performance. , the effect of high crystal quality and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Such as figure 1 As shown, a bismuth vanadate photoanode film, the film structure includes a light absorbing layer, the upper surface of the light absorbing layer is provided with an oxygen evolution catalyst layer, the lower surface of the light absorbing layer is provided with a substrate, the The light absorbing layer is a gradient molybdenum-doped bismuth vanadate thin film, the oxygen evolution catalyst layer is an iron-doped NiO ultra-thin nanosheet, and the substrate is FTO conductive glass. The gradient molybdenum-doped bismuth vanadate thin film is doped with high concentration molybdenum on the surface. The doping concentration of the gradient molybdenum-doped bismuth vanadate thin film is 5% molar ratio.

[0046] The preparation steps of undoped bismuth vanadate thin film are as follows:

[0047] 1) Sputter a bismuth thin film on a dry, clean FTO conductive glass substrate with a length and width of 1 cm × 2 cm using a high vacuum ion sputtering apparatus; ...

Embodiment 2

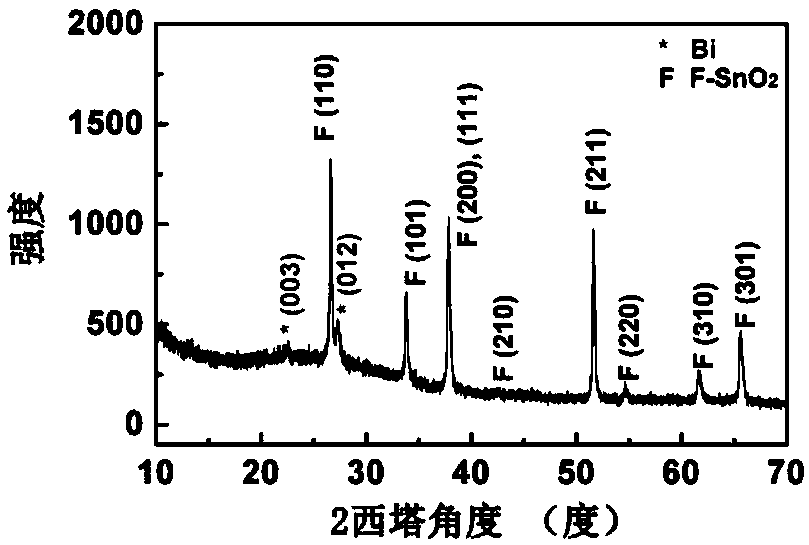

[0051] Similar to Example 1, a metal bismuth film was deposited by sputtering, and 50 microliters of vanadyl acetylacetonate and molybdenum diacetylacetonate oxide in a ratio of 19 / 1 were uniformly coated on the DMSO solution with a molar ratio of 0.5 mol / liter. , through the same drying, heat treatment, soaking, cleaning, drying and other processes as in Example 1, a uniform molybdenum-doped bismuth vanadate film was obtained. Its optical photo is attached figure 2 Medium No. 2 film. Figure 5 It is a uniform molybdenum-doped bismuth vanadate thin film, and all XRD diffraction peaks can be assigned to BiVO 4 phase with F-doped SnO 2 substrate. Figure 13 Example 2 is the performance curve of the photoanodized water prepared by this sample.

Embodiment 3

[0053] Gradient molybdenum-doped bismuth vanadate thin film preparation steps: On the undoped bismuth vanadate thin film obtained in Example 1, drop 50 microliters of vanadyl acetylacetonate and molybdenum diacetylacetonate with a ratio of 19 / 1. DMSO solution with a molar ratio of 0.5 mol / L; dried in an oven at 80-100°C and then placed in a muffle furnace at a rate of 2°C / min to first raise the temperature to 450°C and then to 500°C and keep the temperature at 500°C for 2 hours; After natural cooling, the obtained brown film is soaked in 1 mol / L NaOH solution for 20-30 minutes, washed with distilled water to remove impurity ions, and dried to obtain a gradient molybdenum-doped bismuth vanadate film. Its optical photo is attached figure 2 Medium No. 3 film.

[0054] Figure 6 For gradient molybdenum-doped bismuth vanadate thin films, all XRD diffraction peaks can be attributed to BiVO 4 phase with F-doped SnO 2 substrate. Figure 7 The sample characteristic Raman signals ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bandgap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com