Self-polymeric medical repair material for enhancing rapid fracture repair and application method

A technology for repairing materials and application methods, applied in the field of medical materials, can solve problems such as long repair time, no substantial breakthrough, easy to break again, etc., to improve strength, enhance biocompatibility, and improve normal shape and strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

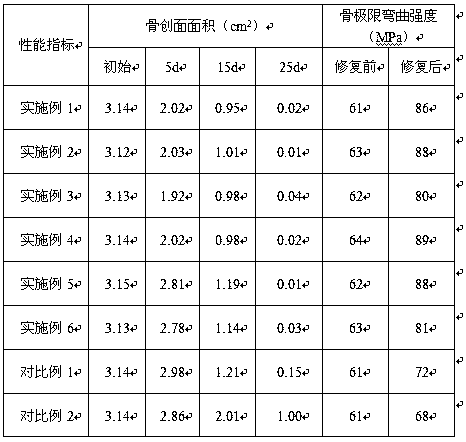

Examples

Embodiment 1

[0029] Medical repair materials are composed of A agent and B agent:

[0030] Agent A consists of 11kg of low molecular weight polybutadiene with a number average molecular weight of 40,000, 32kg of silicone acrylate dispersion, 14kg of polyurethane prepolymer, 17kg of chondroitin, 13kg of silk protein, 9kg of alginic acid, and 4kg of lactide; The B agent is composed of 2kg dibenzoyl peroxide, 1kg ethanedithiol, 2kg diethylaminoethanol, 36kg nano-bone powder, and 59kg nano-cellulose fiber dispersion; the solid content of the silicone acrylate dispersion is 39 %, the component of silicone acrylate is 6kg silicone and 6.48kg acrylate; the solid content of nanocellulose fiber dispersion is 53%, and the average diameter of nanocellulose fiber is 500nm.

[0031] The application process of medical repair materials is:

[0032] Mix Agent A and Agent B evenly at room temperature at a mass ratio of 2:1, and inject it into fractures and bone defects for 8 minutes; fix it with a plaster...

Embodiment 2

[0037] Medical repair materials are composed of A agent and B agent:

[0038]Agent A consists of 8kg of low molecular weight polybutadiene with a number average molecular weight of 30,000, 43kg of silicone acrylate dispersion, 12kg of polyurethane prepolymer, 15kg of chondroitin, 12kg of silk protein, 7kg of alginic acid, and 3kg of lactide; The B agent is composed of 1kg dibenzoyl peroxide, 1kg 1-propanethiol, 1kg glycerin, 30kg nano-bone powder, and 67kg nano-cellulose fiber dispersion; the solid content of the silicone acrylate dispersion is 32%, organic The components of silicon acrylate are 6.76kg of silicone and 7kg of acrylate; the solid content of the nanocellulose fiber dispersion is 48%, and the average diameter of the nanocellulose fibers is 300nm.

[0039] The application process of medical repair materials is:

[0040] Mix Agent A and Agent B uniformly at room temperature at a mass ratio of 3:1, inject into fractures and bone defects, and the injection time is 7 ...

Embodiment 3

[0043] Medical repair materials are composed of A agent and B agent:

[0044] Agent A consists of 12kg of low molecular weight polybutadiene with a number average molecular weight of 50,000, 24kg of silicone acrylate dispersion, 15kg of polyurethane prepolymer, 20kg of chondroitin, 14kg of silk protein, 10kg of alginic acid, and 5kg of lactide; The B agent is composed of 2kg dibenzoyl peroxide, 2kg 1,3-propanedithiol, 3kg trimethylolpropane, 40kg nano-bone powder, 53kg nano-cellulose fiber dispersion; the silicone acrylate dispersion The solid content is 45%, the silicone acrylate component is 5.1kg silicone and 5.7kg acrylate; the solid content of the nanocellulose fiber dispersion is 65%, and the average diameter of the nanocellulose fiber is 800nm.

[0045] The application process of medical repair materials is:

[0046] Mix Agent A and Agent B uniformly at room temperature at a mass ratio of 3:1, inject into fractures and bone defects, and the injection time is 9 minutes;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com