Chemical copper plating solution

A technology of electroless copper plating and divalent copper, which is applied in the direction of liquid chemical plating, metal material coating process, coating, etc., can solve problems such as unevenness, heavy structure, rough surface, etc., and achieve no blistering and improved The effect of rough surface and low internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] The present embodiment provides a kind of electroless copper plating liquid, by mass concentration, comprises following component:

[0063] Copper sulfate pentahydrate 5g / L, formaldehyde 3g / L, potassium sodium tartrate 30g / L, glycine 0.5g / L and stabilizer;

[0064] Wherein, the solvent is deionized water, the stabilizer consists of 0.001g / L of thiourea, 0.0001g / L of bipyridyl and 0.001g / L of potassium tetracyanonickel (II) hydrate, and the solution is made of sodium hydroxide Adjust the pH to 11.

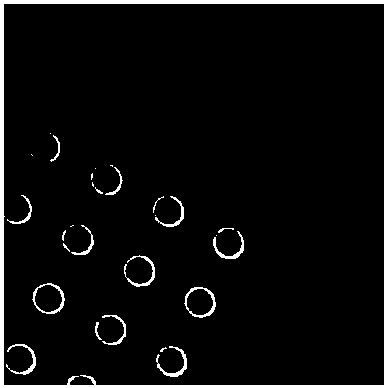

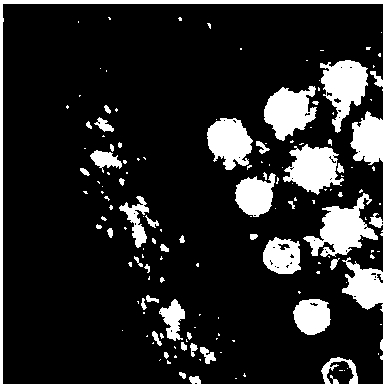

[0065] The copper deposition rate of the electroless copper plating solution provided in this example is 0.63 μm / 6min during plating; the copper deposition layer is well combined with the PI film, and there is no bubble phenomenon; the rolled copper foil flexible PCB after electroless copper plating and electroplating The surface roughness test results of the board are as follows Figure 1a As shown, its surface is bright without white spots.

Embodiment 2

[0071] The present embodiment provides a kind of electroless copper plating liquid, by mass concentration, comprises following component:

[0072] Copper sulfate pentahydrate 8g / L, formaldehyde 5g / L, sodium citrate 60g / L, iminodiacetic acid 0.8g / L and stabilizer;

[0073] Wherein, the solvent is deionized water, the stabilizer consists of 0.001g / L of thiourea, 0.0001g / L of bipyridyl and 0.001g / L of potassium tetracyanonickel (II) hydrate, and the solution is made of sodium hydroxide Adjust the pH to 11.5.

[0074] The copper deposition rate of the electroless copper plating solution provided in this example is 0.58 μm / 6min during plating; the copper deposition layer is well combined with the PI film, and there is no bubble phenomenon; the rolled copper foil flexible PCB after electroless copper plating and electroplating The surface roughness test results of the board are as follows Figure 2a As shown, its surface is bright without white spots.

Embodiment 3

[0079] The present embodiment provides a kind of electroless copper plating liquid, by mass concentration, comprises following component:

[0080] Copper sulfate pentahydrate 10g / L, sodium hypophosphite 30g / L, disodium edetate 40g / L, 2-mercaptobenzothiazole 0.01g / L and stabilizer;

[0081] Wherein, the solvent is deionized water, the stabilizer consists of 0.001g / L of thiourea, 0.0001g / L of bipyridyl and 0.001g / L of potassium tetracyanonickel (II) hydrate, and the solution is made of sodium hydroxide Adjust pH to 12.

[0082] The copper deposition rate of the electroless copper plating solution provided in this example is 0.65 μm / 6min during plating; the copper deposition layer is well combined with the PI film, and there is no bubble phenomenon; the rolled copper foil flexible PCB after electroless copper plating and electroplating The surface roughness test results of the board are as follows Figure 3a As shown, its surface is bright without white spots.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com