Nano copper electrode material as well as preparation method and application thereof

An electrode material, nano-copper technology, applied in the field of nano-materials, can solve the problems of poor selectivity, low activity, high hydrogen evolution activity, etc., and achieve the effects of increased selectivity, enhanced mass transfer rate, and high working stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

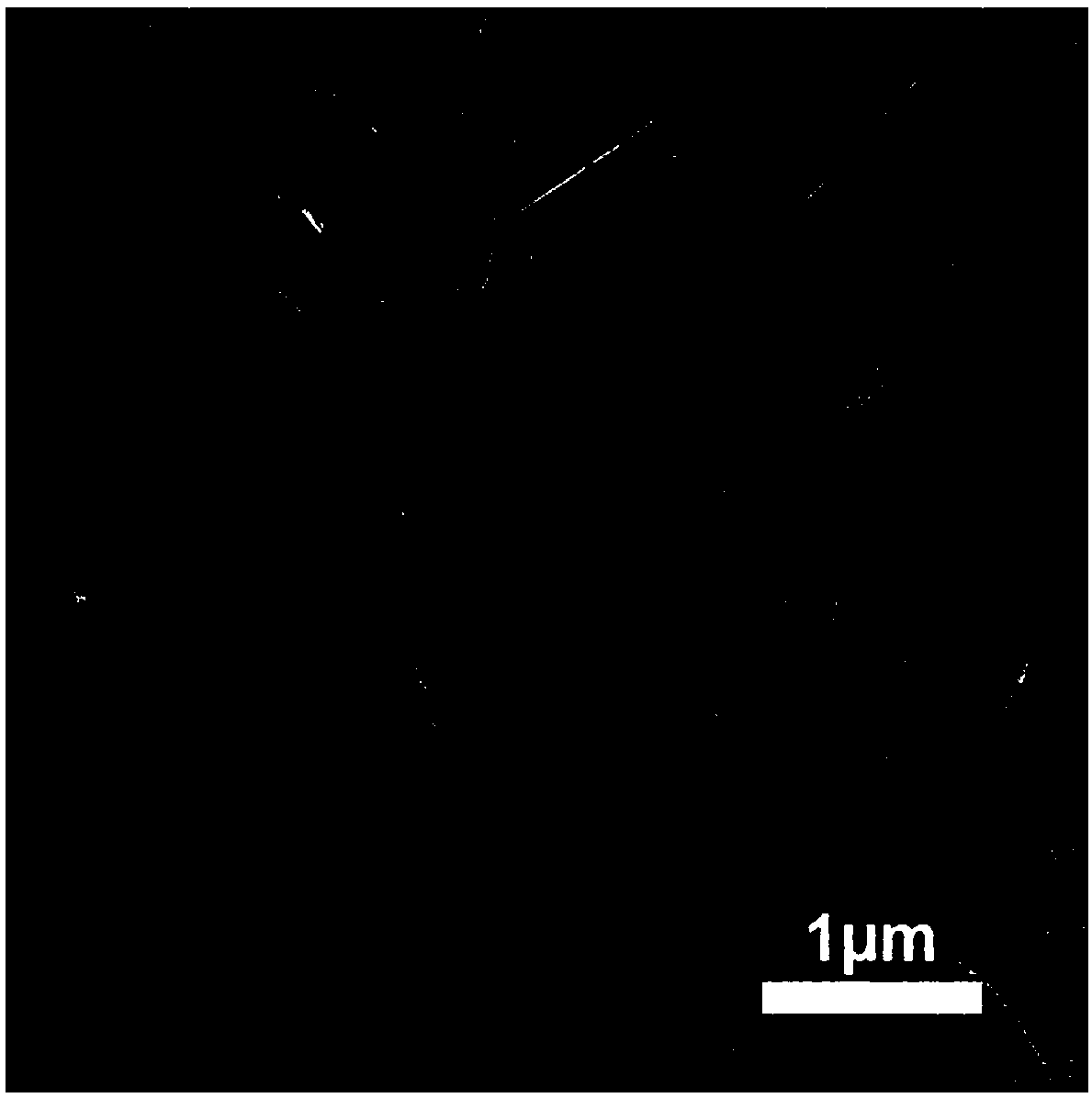

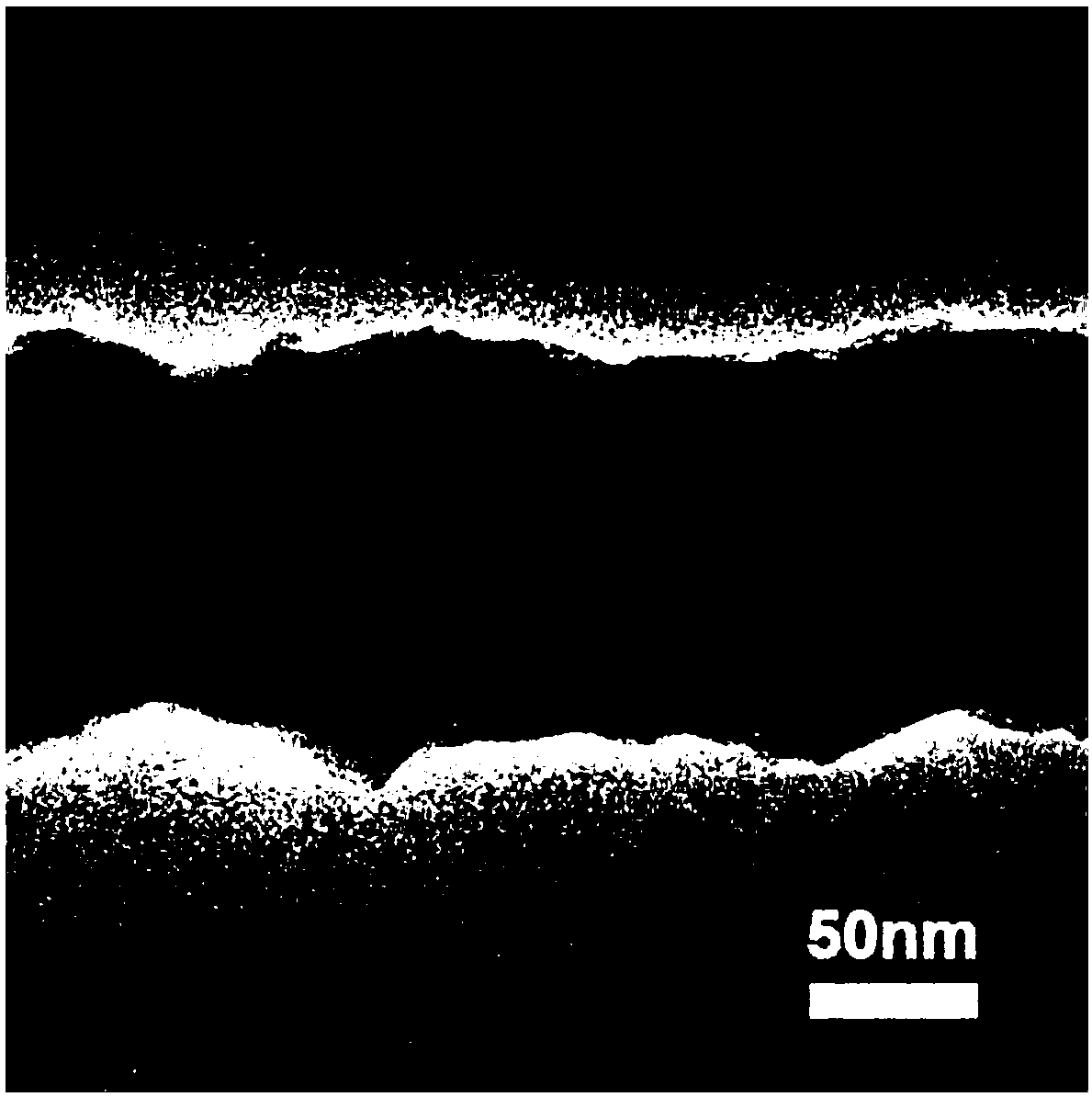

[0041] The superaerophilic copper nanowire aggregate electrode material was prepared by the following steps:

[0042] A. prepare reaction solution, prepare the copper sulfate solution of 0.1mol / L, the sodium hydroxide solution of 14.5mol / L and the hydrazine solution that mass concentration is 35%; And the polytetrafluoroethylene water dispersion liquid that mass concentration is 10% and 0.1mol / L potassium bicarbonate solution;

[0043] B. Add 6 mL of copper sulfate solution with a concentration of 0.1 mol / L to 120 mL of sodium hydroxide solution with a concentration of 14.5 mol / L, then add 760 μL of ethylenediamine, preheat to 70°C, and then add 60 μL with a mass concentration of 35 % hydrazine solution, reacted at 70°C for 2 hours to obtain a copper nanowire dispersion;

[0044]C. Uniformly disperse the copper nanowire dispersion liquid obtained in step B in absolute ethanol; add 15 μ L of polytetrafluoroethylene dispersion liquid with a mass concentration of 10% to 1 mL of ...

Embodiment 2

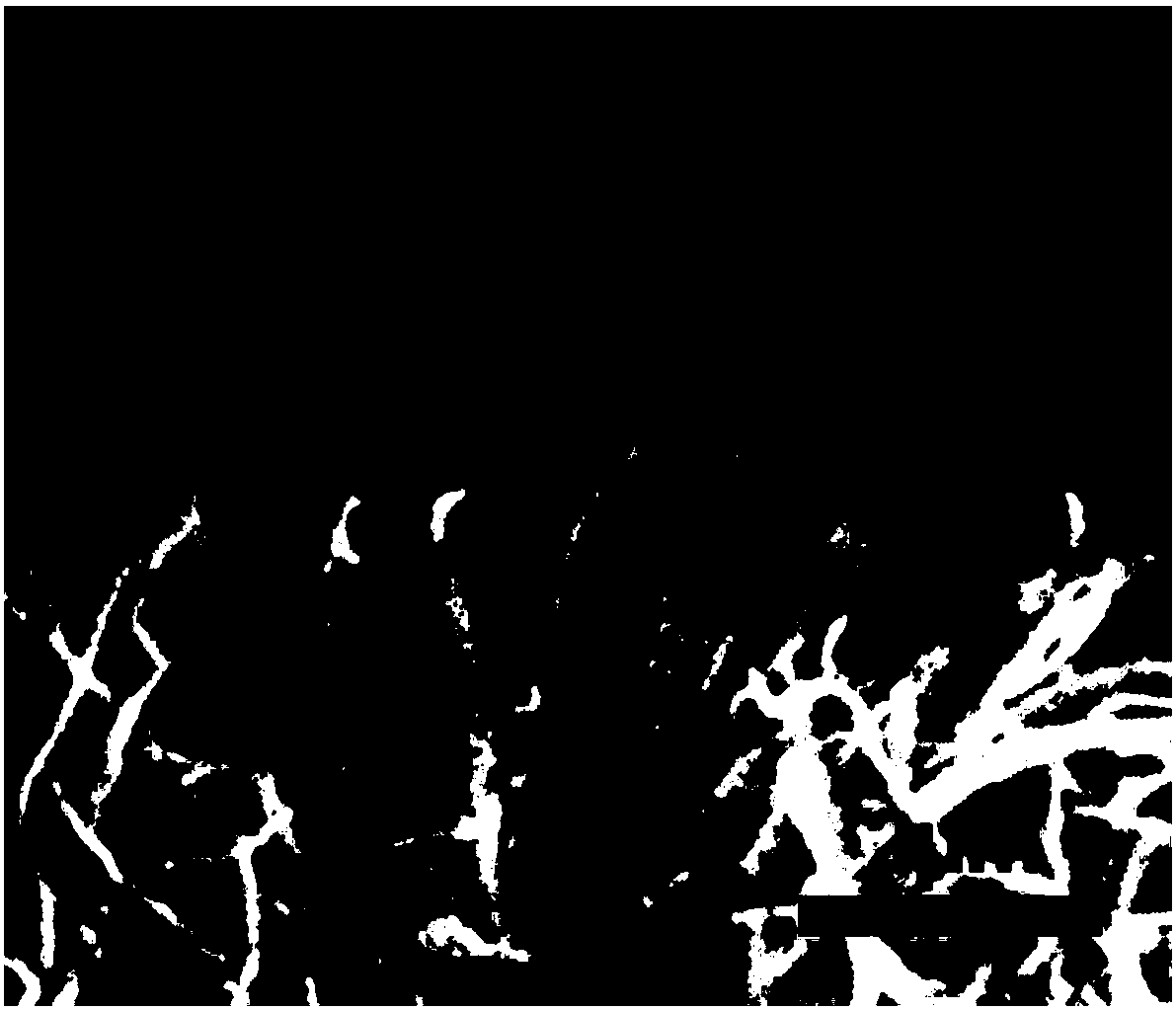

[0057] Prepare super aerophilic copper nanowire array electrode material by the following steps:

[0058] a. preparation reaction solution, concentration is the mixed solution of the sodium hydroxide of 2.66mol / L and the ammonium persulfate that concentration is 0.13mol / L; Mass concentration is the polytetrafluoroethylene dispersion liquid of 5%; The carbonic acid of 0.1mol / L potassium hydrogen solution;

[0059] b. Pretreat the copper foil of the conductive base, ultrasonically clean it in acetone, dilute hydrochloric acid and deionized water for 10 minutes in sequence, and then immerse the pretreated copper foil in step a with a concentration of 2.66mol / L of sodium hydroxide and a concentration of In a mixed solution of 0.13mol / L ammonium persulfate, take it out after reacting for 10 minutes, wash and dry, and obtain a copper foil with a copper hydroxide nanowire array;

[0060] c. Put the copper foil with the copper hydroxide nanowire array obtained in step b into the poly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com