A kind of preparation method of catalytic oxygen release clean fuel

A technology for clean fuel and preparation steps, which is applied to fuels, fuel additives, liquid carbon-containing fuels, etc., can solve the problems of emission of harmful gases, insufficient calorific value, low combustion rate, etc., and achieves improved combustion efficiency and broad application prospects. , the effect of promoting oxidative combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

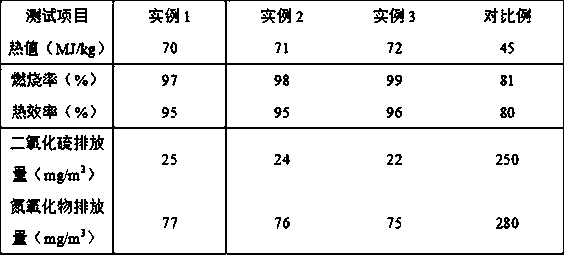

Examples

example 1

[0026] Add 100 g of tantalum hydroxide and 1.5 L of phosphoric acid solution with a mass fraction of 10% into the stirring tank, start the stirrer, stir and react at a speed of 200 r / min for 2 days, and age at room temperature for 12 hours to obtain an aged sol. Sol sol suction filtration, remove the filtrate to obtain a filter cake, rinse the filter cake with deionized water until the washing liquid is neutral, place the washed filter cake in a vacuum drying box with a set temperature of 110 ° C, and dry for 2 hours to obtain dry solids , put the dry solid into a mortar and grind, pass through a 200-mesh sieve to obtain powder, put the powder into a muffle furnace, heat up to 300 ° C, and calcine for 3 hours to obtain a solid acid catalyst; by weight, 20 parts Straw, 30 parts of grass seed husks, and 20 parts of corncob were put into the fermentation tank, and 30 parts of deionized water, 20 parts of sulfuric acid solution with a mass fraction of 5%, and 4 parts of Clostridium...

example 2

[0028] Add 110g of tantalum hydroxide and 1.7L of phosphoric acid solution with a mass fraction of 10% into the stirring tank, start the stirrer, stir and react at a speed of 220r / min for 2 days, and age at room temperature for 14h to obtain an ageing sol. The sol was suction filtered, the filtrate was removed to obtain a filter cake, the filter cake was washed with deionized water until the washing liquid was neutral, and the washed filter cake was placed in a vacuum drying box with a set temperature of 115 ° C, and dried for 2.5 hours to obtain a dry For solid, put the dry solid into a mortar and grind, pass through a 200-mesh sieve to obtain powder, put the powder into a muffle furnace, heat up to 320 ° C, and calcine for 3.5 h to obtain a solid acid catalyst; Put 25 parts of straw, 32 parts of grass seed husks, and 22 parts of corncob into a fermenter, add 35 parts of deionized water, 25 parts of sulfuric acid solution with a mass fraction of 5%, and 4 parts of Clostridium ...

example 3

[0030] Add 120 g of tantalum hydroxide and 2.0 L of phosphoric acid solution with a mass fraction of 10% into the stirring tank, start the stirrer, stir and react at a speed of 250 r / min for 3 days, and age at room temperature for 15 hours to obtain an aged sol. The sol was filtered with suction, the filtrate was removed to obtain a filter cake, the filter cake was washed with deionized water until the washing liquid was neutral, and the washed filter cake was placed in a vacuum drying box with a set temperature of 120 ° C, and dried for 3 hours to obtain a dry solid , put the dry solid into a mortar and grind, pass through a 200-mesh sieve to obtain powder, put the powder into a muffle furnace, heat up to 350 ° C, and calcine for 4 hours to obtain a solid acid catalyst; by weight, 30 parts Straw, 35 parts of grass seed husks, and 25 parts of corncob were put into the fermentation tank, and 40 parts of deionized water, 30 parts of sulfuric acid solution with a mass fraction of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com