Method for preparing inorganic nanoparticle/aromatic polyimide composite film and composite film prepared according to method

A polyimide film, inorganic nanoparticle technology, applied in the direction of coating, can solve the problems of low interface bonding strength, low selectivity, molecular weight drop, etc. The effect of improving selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

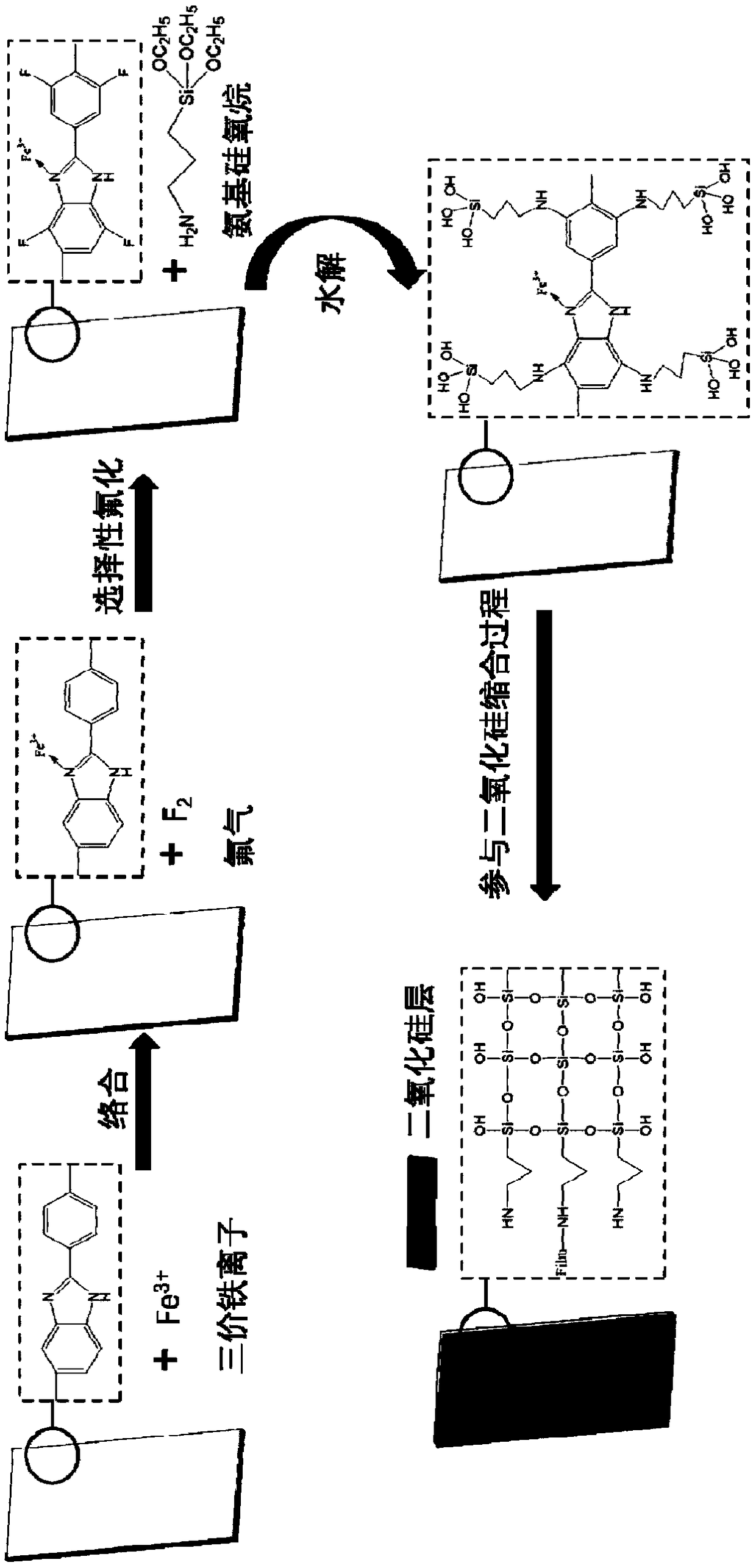

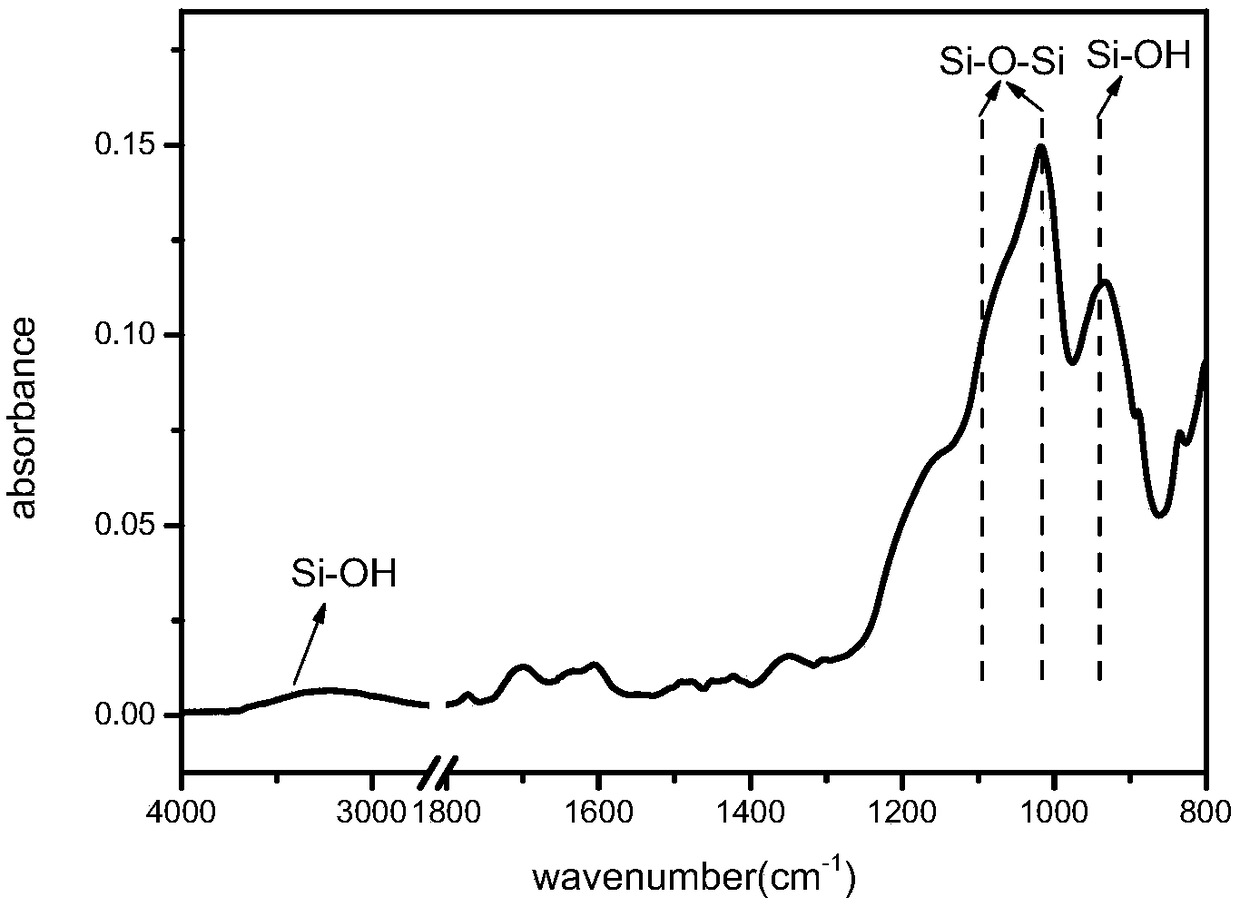

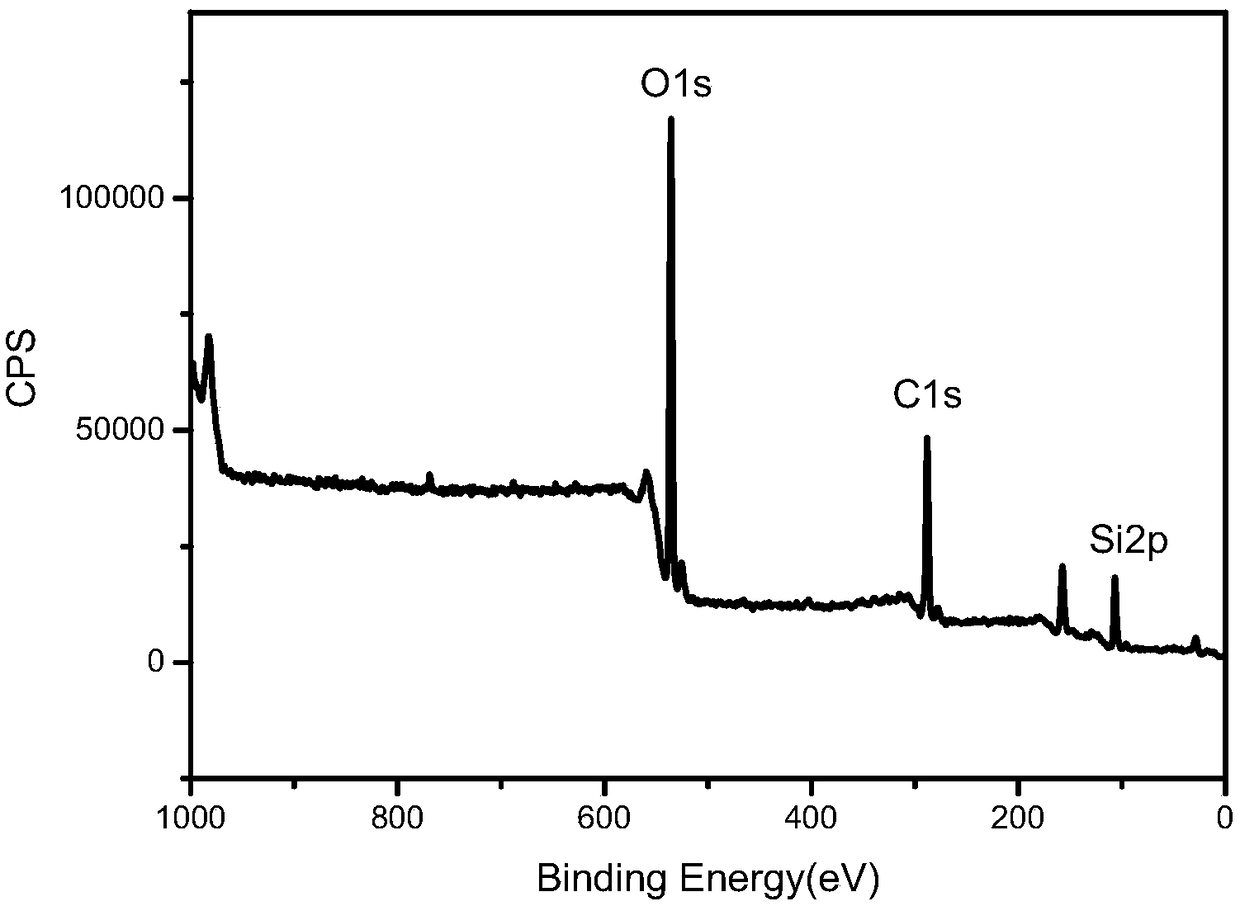

Method used

Image

Examples

Embodiment 1

[0059] First prepare the polyimide film with the monomer molar ratio of BPDA:PABZ=1:1, and then statically soak the film in Fe 3+ The mass concentration is 0.02g / mL, and the volume concentration of water is 1% ethanol solution, after the complexation reaction 6h, dry, and then pass through the concentration of 200Pa / g F 2 / N 2 (F 2 The volume fraction is 10%) fluorination for 20min, followed by static immersion at 80°C in an ethanol solution containing 50% aminopropyltriethoxysilane by mass fraction of the solution, reacting for 3h and drying, then statically immersing the membrane in pH =3 in nitric acid aqueous solution for 10 minutes and then dried, and finally hydrolyzed tetraethyl orthosilicate with a hydrochloric acid catalytic concentration of 50% of the mole fraction of the solution to obtain silica sol, which was spin-coated twice on the film and baked at 100°C Just dry for 10 hours.

Embodiment 2

[0061] First prepare a polyimide film with a monomer molar ratio of BPDA:PMDA:ODA:PABZ=1:1:1:1, and then statically soak the film in Ni 2+ The mass concentration is 0.01g / mL, and the volume concentration of water is 1% ethanol solution, after the complexation reaction for 1h, it is dried, and then the F with a concentration of 1000Pa / g is passed through 2 / N 2 (F 2 The volume fraction is 10%) fluorination for 1min, followed by static immersion at 30°C in an ethanol solution containing 10% of the solution mass fraction of aminopropyltrimethoxysilane and 10% of the solution mass fraction of 3-aminopropyltrihydroxysilane In the process, dry after reacting for 5 hours, then statically immerse the film in an aqueous solution of oxalic acid with pH=6 for 60 minutes and then dry it for 60 minutes, and finally hydrolyze aluminum isopropoxide with a phosphoric acid catalytic concentration of 90% of the mole fraction of the solution to obtain an aluminum sol. Immerse the film in the s...

Embodiment 3

[0063] First prepare the polyimide film with the monomer molar ratio of BPDA:PDA:PABZ=10:9:1, and then statically soak the film in Cu 2+ The mass concentration is 0.015g / mL, the volume concentration of water is in the ethanol solution of 0.5%, dry after 8h of complexation reaction, then feed the F with concentration of 500Pa / g 2 / N 2 (F 2 10% by volume) fluorination for 5 minutes, then statically soaked in an ethanol solution containing 3-mercaptopropyltriethoxysilane with a mass fraction of 50% of the solution at 90°C, reacted for 1 hour, dried, and then statically soaked the membrane After hydrolysis reaction in aqueous sulfuric acid solution with pH=3 for 30 minutes, dry it, and finally hydrolyze butyl titanate with nitric acid catalytic concentration of 1% of the mole fraction of the solution to obtain titanium sol, immerse the film in the sol and pull it 5 times, and bake at 40°C Just dry for 24 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com