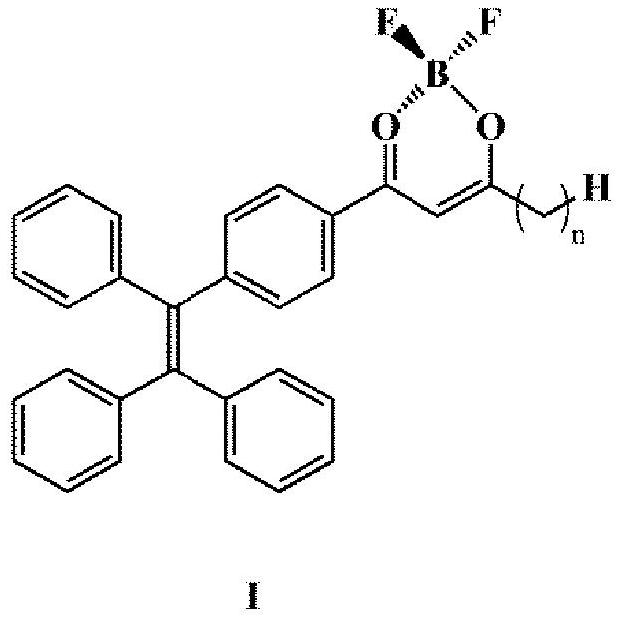

A kind of alkyl side chain phenyl boron fluoride complex and its preparation method and application

A technology of chain phenyl boron and complex compound, which is applied to alkyl side chain phenyl boron fluorine complex and its preparation method and application field, can solve the problem of less piezochromic materials, harsh synthesis conditions, complex synthesis process, etc. problem, to achieve the effect of short reaction period, broaden application market and simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

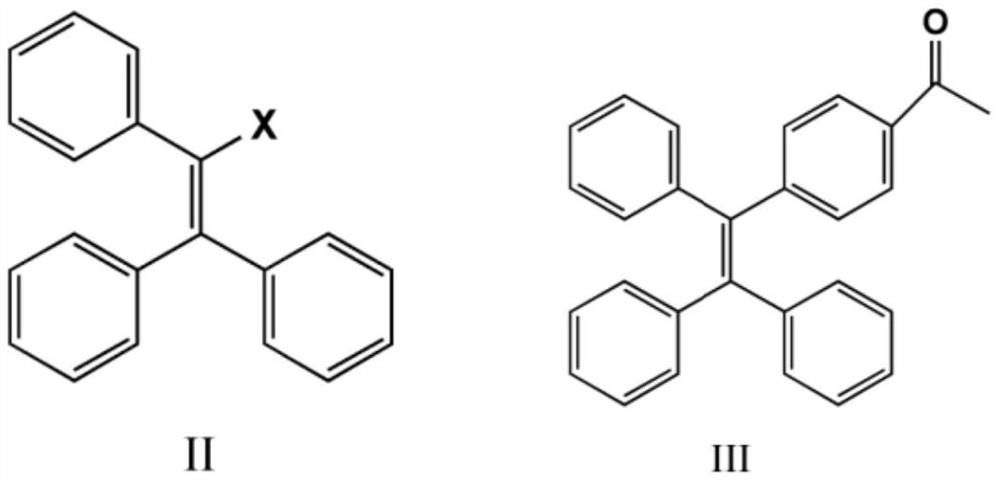

Embodiment 1

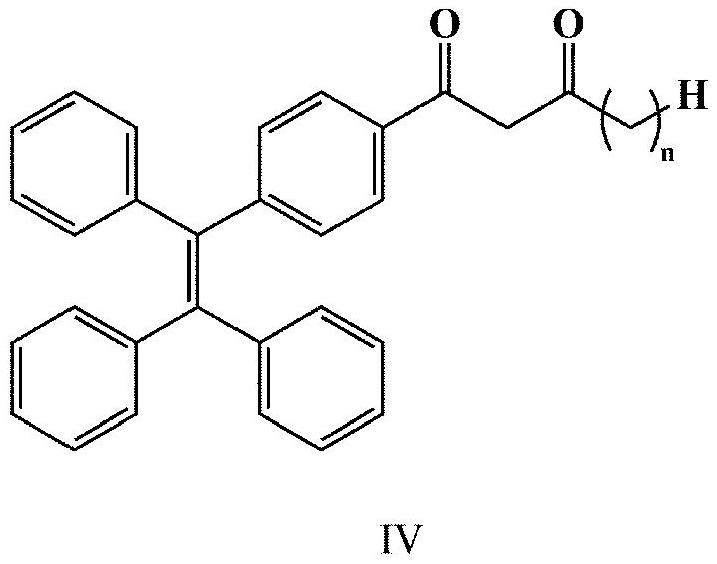

[0031] (1) Mix 7.5g (22.35mmol) of 2-bromo-1,1,2-triphenylethylene (II) with 3.75g (22.85mmol) of 4-acetylphenylboronic acid and 0.05g (0.0435mmol) of four Triphenylphosphine palladium, 5.5g (39.8 mmol) of potassium carbonate, 3.61g (11.2 mmol) of tetrabutylammonium bromide were added to a dry reaction vessel with nitrogen, and 80ml of toluene was added as a solvent, and heated to reflux at 100°C for 24 hours, cooled to room temperature, and extracted the crude product of tetrastyryl monoketone (Ⅲ) with dichloromethane, petroleum ether: dichloromethane=1:1 for column chromatography to obtain 6.68g white solid, yield 80% .

[0032] (2) Add the above-mentioned 1.56g (4 mmol) white solid and 0.37g (4 mmol) methyl propionate into a dry reaction vessel with nitrogen, add solvent 30ml tetrahydrofuran, after the white solid is completely dissolved, add 0.3975g (16.5 mmol) sodium hydride, heated to reflux at 50°C, reacted for 4 hours, cooled to room temperature, and the product was r...

Embodiment 2

[0035] (1) Mix 7.5g (22.39mmol) of 2-bromo-1,1,2-triphenylethylene (II) with 4.03g (24.58mmol) of 4-acetylphenylboronic acid and 0.06g of tetrakistriphenylphosphine palladium , 5.96g of potassium carbonate and 3.97g of tetrabutylammonium bromide were added to a dry reaction vessel with nitrogen, 80ml of xylene was added, heated to reflux at 100°C for 24 hours, cooled to room temperature, and tetraphenylethylene was extracted with dichloromethane The crude product of monoketone (Ⅲ), petroleum ether: dichloromethane = 1:1, was subjected to column chromatography to obtain 6.71 g of white solid with a yield of 80%.

[0036] (2) Add the above 1.56g (4 mmol) white solid and 1.11g (12 mmol) methyl propionate into a dry reaction vessel with nitrogen, add 30ml of solvent methylene chloride, and wait until the white solid is completely dissolved , add 0.3975g (16.5 mmol) sodium hydride, heat to reflux at 55°C, react for 3 hours, cool to room temperature, spin evaporate the product to sl...

Embodiment 3

[0039](1) Mix 7.5g (22.39mmol) of 2-bromo-1,1,2-triphenylethylene (II) with 3.75g (22.87mmol) of 4-acetylphenylboronic acid and 0.05g (0.0435mmol) of four Triphenylphosphine palladium, 5.5g (39.8 mmol) of potassium carbonate, 3.61g (11.2 mmol) of tetrabutylammonium bromide were added to a dry reaction vessel with nitrogen, 80ml of toluene was added, and heated to reflux at 100°C for 24 hours , cooled to room temperature, and dichloromethane was used to extract the crude product of tetrastyryl monoketone (Ⅲ), petroleum ether: dichloromethane = 1:1, and column chromatography was performed to obtain 6.68 g of white solid, with a yield of 80%.

[0040] (2) Add 1.56g (4 mmol) of the above white solid and 0.413g (4 mmol) of methyl butyrate into a dry reaction vessel with nitrogen, add 30ml of solvent tetrahydrofuran, and after the white solid is completely dissolved, add 0.3975g (16.5 mmol) sodium hydride, heated to reflux at 60 ° C, reacted for 5 hours, cooled to room temperature, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com