Method for preparing porous bacterial cellulose membrane

A technology of bacterial cellulose membrane and sodium carboxymethyl cellulose, which is applied in the field of preparation of porous bacterial cellulose membrane, can solve the problems of unfriendly environment, degraded cellulose chain, complicated operation process, etc., and the method is simple and easy, Improve air permeability and prevent sedimentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] The preparation and parameter monitoring of the seed liquid in the embodiment of the present invention can refer to the existing method, wherein the seed liquid can be prepared by the following steps:

[0018] The strains preserved at 4°C were kept at 30°C for 20 minutes, and a ring of strains was picked up with an inoculation loop and streaked on the solid plate medium, and the plate was cultured in a 30°C incubator for 36 hours. Composition of solid medium (g / 100mL): glucose 2.0, sucrose 1.0, magnesium sulfate 0.04, citric acid 0.11, sodium dihydrogen phosphate 0.25, peptone 1.0, agar 1.8, yeast extract powder 0.1. pH=6.0, sterilized at 121°C for 30 minutes;

[0019] The activated seeds were inoculated into a 500mL Erlenmeyer flask filled with 1 / 5 of the seed solution, and then placed in a shaker with reciprocating shaking at 120-160rpm for 48h. Seed solution composition (g / 100mL): glucose 2.0, ammonium sulfate 0.6, potassium dihydrogen phosphate 0.1, magnesium sulfa...

Embodiment 1

[0025] 1mg / 100mL of calcium carbonate and 40mg / 100mL of sodium carboxymethylcellulose were added to the fermentation broth, and the Acetobacter xylinum seed solution in the logarithmic growth phase was inoculated into the fermentation broth to carry out fermentation according to the inoculation amount of 10%. After the fermentation, the cellulose membrane was washed with 5 g / L acetic acid to remove calcium carbonate, followed by conventional rinsing and purification to obtain a porous bacterial cellulose membrane.

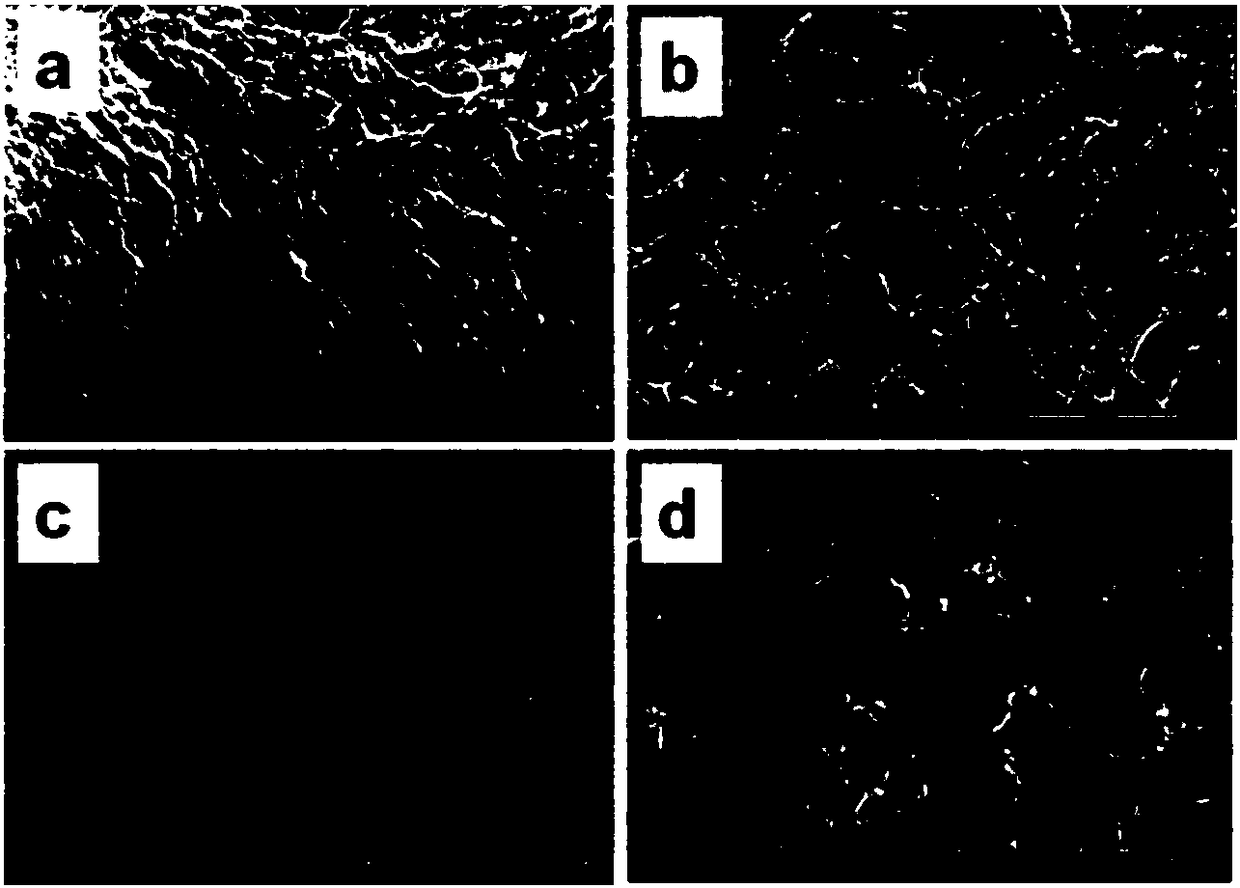

[0026] Adding calcium carbonate and sodium carboxymethyl cellulose to ferment the bacterial cellulose film obtained with no addition of calcium carbonate and sodium carboxymethyl cellulose to the scanning electron microscope of the bacterial cellulose film obtained by fermentation figure 1 shown, where figure 1 (a) and figure 1 (b) adding calcium carbonate and sodium carboxymethyl cellulose to ferment the bacterial cellulose film obtained, figure 1 (c) and figur...

Embodiment 2

[0029] Add 3mg / 100mL of calcium carbonate and 195mg / 100mL of sodium carboxymethylcellulose to the fermentation broth, and inoculate the Acetobacter xylinum seed solution in the logarithmic growth phase into the fermentation broth according to the inoculation amount of 10%. After the fermentation, the cellulose membrane was washed with 15 g / L acetic acid to remove calcium carbonate, followed by conventional rinsing and purification to obtain a porous bacterial cellulose membrane.

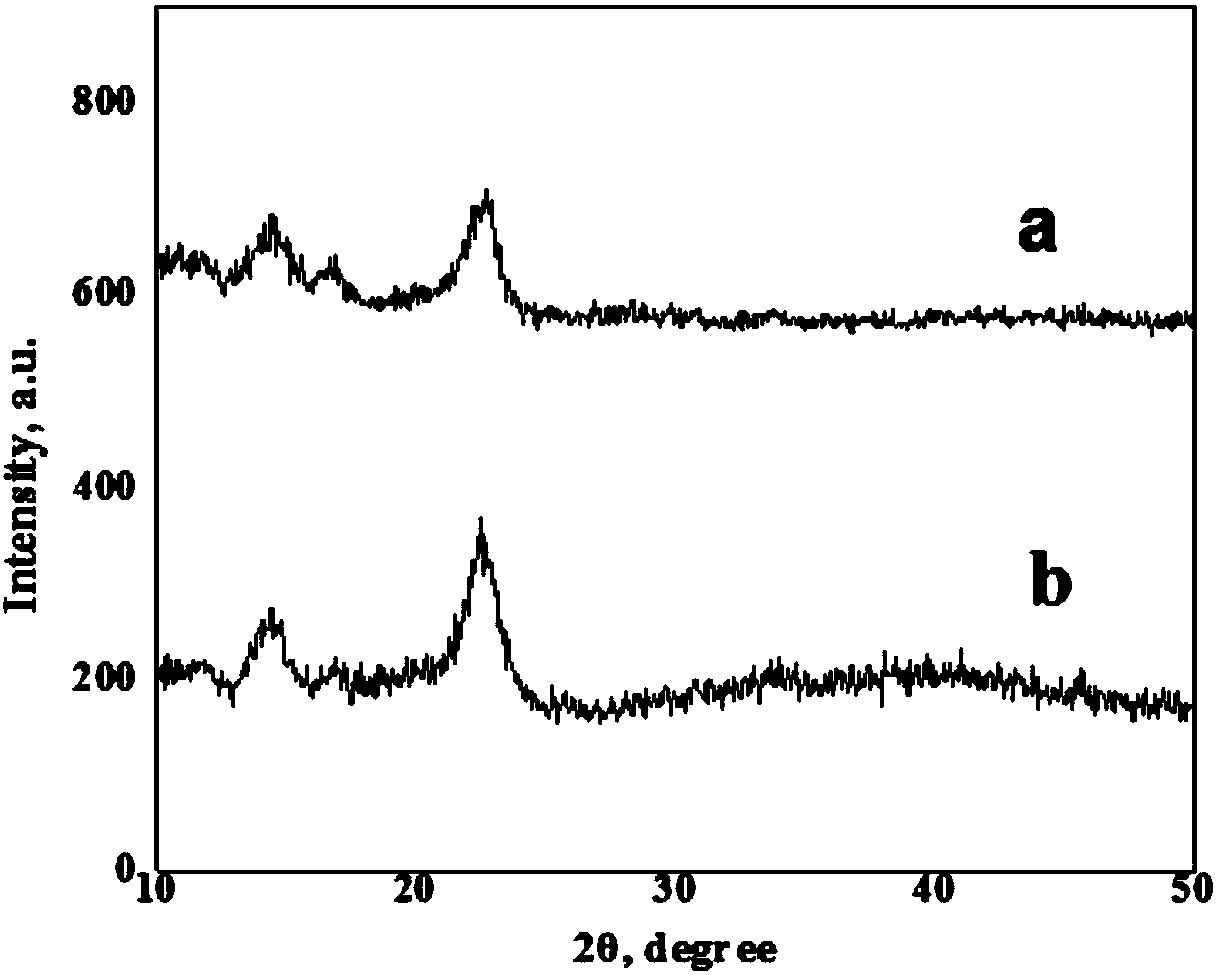

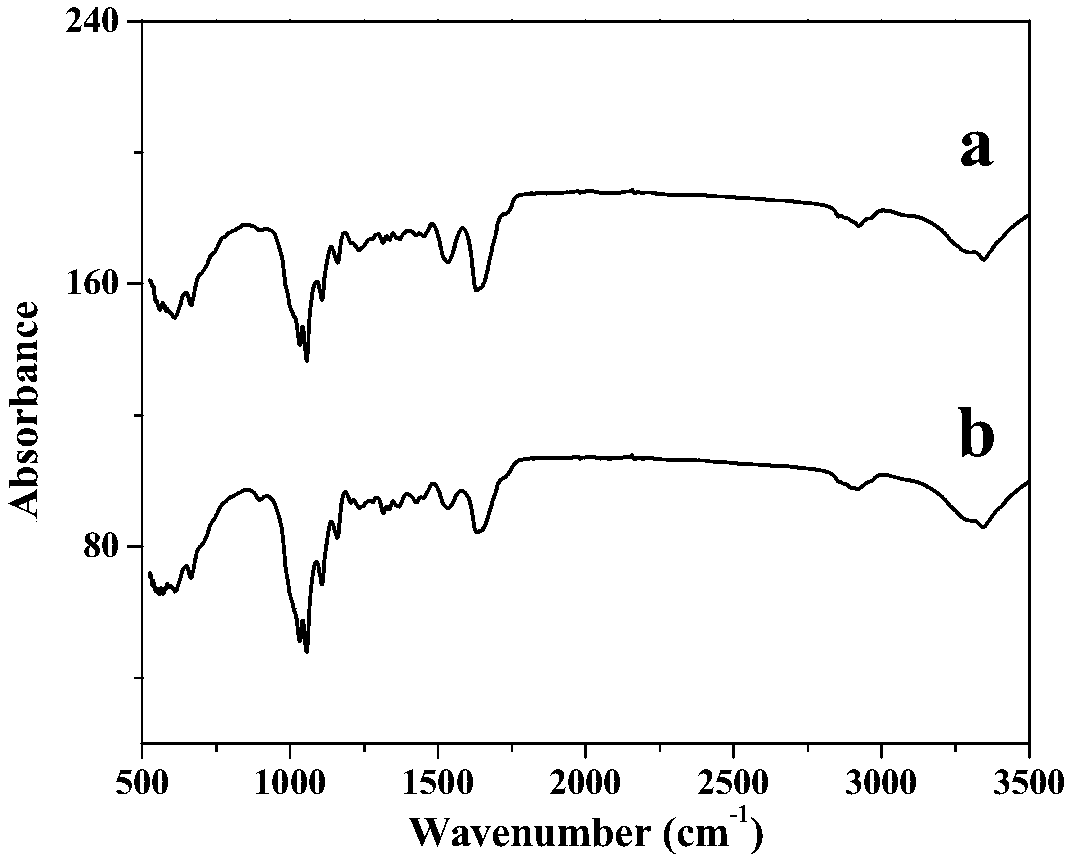

[0030] Add calcium carbonate and sodium carboxymethyl cellulose to ferment the bacterial cellulose film that obtains and do not add calcium carbonate and sodium carboxymethyl cellulose to ferment the XRD figure of the bacterial cellulose film that obtains figure 2 Shown, a is adding calcium carbonate and sodium carboxymethyl cellulose, b is not adding calcium carbonate and sodium carboxymethyl cellulose. It can be seen from the figure that the BC film has typical strong diffraction peaks at 2θ of 17...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com