Preparation method for mesoporous silica coated gold nanorod doping integral column

A technology of mesoporous silica and gold nanorods, applied in chemical instruments and methods, alkali metal oxides/hydroxides, inorganic chemistry, etc., can solve the complex synthesis process of RTIL, accelerate the speed of polymerization reaction, and difficult to volatilize and other problems, to achieve the effect of good permeability, improved separation ability and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] To confirm GNRs@mSiO 2 In the synthesis of capillary monolithic columns, we prepared two kinds of capillary monolithic columns, one is doped GNRs@mSiO 2 capillary monolithic column, the other is undoped GNRs@mSiO 2 The capillary monolithic column, and scanning electron microscope analysis was carried out on the two monolithic columns to characterize the morphological characteristics of the particles. The specific operation steps are as follows:

[0026] Doped GNRs@mSiO 2 Preparation method of capillary monolithic column:

[0027] The porogen GNRs@mSiO 2 / choline chloride-ethanol and ionic liquid 30.61% (both mass percent), 1-hexyl-3-methylimidazolium tetrafluoroborate [HMIM]BF 4 49.88%, functional monomer methacrylic acid 1.86% and butyl methacrylate 9.21%, initiator ammonium persulfate 0.31% and tetramethylethylenediamine 3.98%, crosslinking agent ethylene glycol dimethacrylate 4.15% After mixing, the mixture was sonicated at low temperature for 15 min (300 W), an...

Embodiment 2

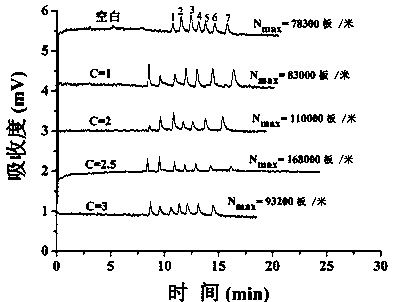

[0033] In order to investigate doped GNRs@mSiO 2 GNRs@mSiO in capillary monolithic column 2 The influence of the concentration dispersed in choline chloride-ethanol on the performance of capillary monolithic column, GNRs@mSiO with different concentrations were synthesized 2 -The monolithic column of choline chloride-ethanol uses acetone as a marker to separate alkylbenzene analogs (acetophenone, butyrophenone, toluene, ethylbenzene, propylbenzene, butylbenzene), and the electrochromatographic conditions are : 12 kV, 254 nm, ACN: 10 mmol / L acetate buffer (pH 6.0) (70 / 30, v / v), for the results of electrochromatographic experiments see figure 2 .

[0034] The results show that when no doping GNRs@mSiO 2 When (that is, blank), the capillary monolithic column has low separation efficiency for alkylbenzene analogs, and the peak eluting time is late, and the peak tailing is serious. Doped GNRs@mSiO 2 The capillary monolithic column with GNRs@mSiO in the polymerization system 2...

Embodiment 3

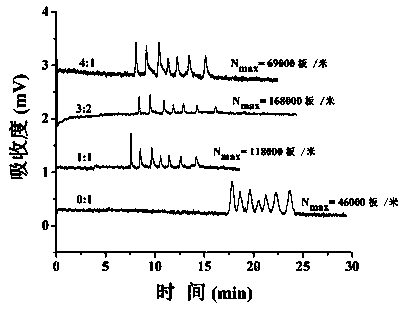

[0036] In order to investigate the effect of the ratio of ionic liquid and choline chloride-ethanol in the porogen on the separation performance of capillary monolithic columns, four monolithic columns with different ratios of ionic liquid and choline chloride-ethanol were synthesized and acetone was used as a marker , separation of alkylbenzene analogues (acetophenone, butyrophenone, toluene, ethylbenzene, propylbenzene, butylbenzene), electrochromatographic conditions: 12 kV, 254nm, ACN: 10 mmol / L acetate buffer solution (pH 6.0) (70 / 30, v / v), the results of electrochromatographic experiments are shown in image 3 .

[0037] The results show that with the decrease of the ionic liquid in the porogen system, the maximum column efficiency for the separation of p-alkylbenzene analogs increases first and then decreases. When the ratio of ionic liquid to deep eutectic solvent is 3:2 , the highest column efficiency and highest resolution are achieved. When the proportion of ionic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com