Energy-saving and environment-friendly thermal insulation material and preparation method thereof

A thermal insulation material, energy-saving and environmental-friendly technology, applied in the field of thermal insulation, can solve the problems of poor crack resistance and dimensional shrinkage resistance, achieve good flame retardancy, improve thermal insulation performance, and improve crack resistance and dimensional shrinkage resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

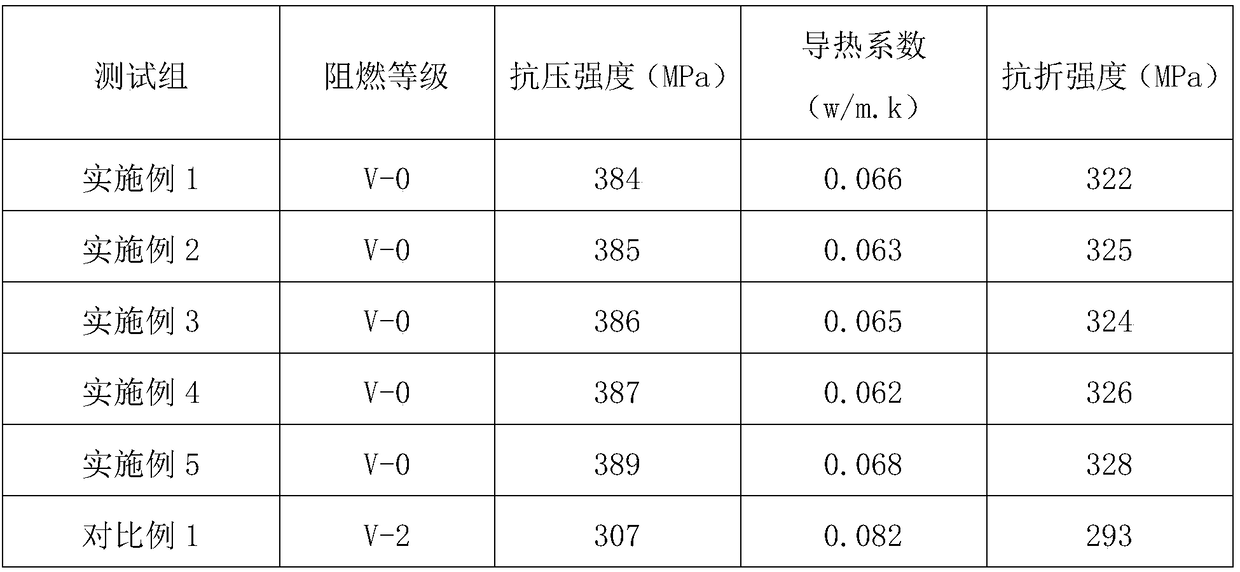

Examples

Embodiment 1

[0030] An energy-saving and environment-friendly thermal insulation material, comprising the following raw materials in parts by weight:

[0031] 8 parts of calcium carbonate powder, 12 parts of industrial cinder, 5 parts of aluminum oxide, 2 parts of aluminum stearate, 8 parts of waste asbestos, 5 parts of polypropylene fiber, 11 parts of bamboo charcoal powder, 12 parts of coconut shell powder, 7 parts of attapulgite , 8 parts of quartz powder, 11 parts of potassium feldspar, 12 parts of montmorillonite, 15 parts of waste polyethylene foam, 20 parts of Portland cement, 0.8 part of sodium pyrophosphate, 0.6 part of penetrant, 0.6 part of water reducing agent, 0.4 parts of foaming agent and 10 parts of water.

[0032] The penetrant is sodium alkylsulfonate.

[0033] The water reducer is sodium lignosulfonate.

[0034] The foaming agent is composed of potassium borohydride, phthalic anhydride and ferric nitrate in a mass ratio of 3:1:1.

[0035] The preparation method of the...

Embodiment 2

[0045] An energy-saving and environment-friendly thermal insulation material, comprising the following raw materials in parts by weight:

[0046] Calcium carbonate powder 15 parts, industrial cinder 25 parts, aluminum oxide 12 parts, aluminum stearate 5 parts, waste asbestos 15 parts, polypropylene fiber 9 parts, bamboo charcoal powder 18 parts, coconut shell powder 18 parts, attapulgite 16 parts , 13 parts of quartz powder, 23 parts of potassium feldspar, 17 parts of montmorillonite, 21 parts of waste polyethylene foam, 28 parts of Portland cement, 2 parts of sodium pyrophosphate, 1.2 parts of penetrating agent, 1.2 parts of water reducing agent, 0.8 parts of foaming agent and 15 parts of water.

[0047] The penetrant is sodium alkylbenzene sulfonate.

[0048] The water reducer is calcium lignosulfonate.

[0049] The foaming agent is composed of potassium borohydride, phthalic anhydride and ferric nitrate in a mass ratio of 3:1:1.

[0050] The preparation method of the energ...

Embodiment 3

[0060] An energy-saving and environment-friendly thermal insulation material, comprising the following raw materials in parts by weight:

[0061] 10 parts of calcium carbonate powder, 17 parts of industrial cinder, 7 parts of aluminum oxide, 3 parts of aluminum stearate, 10 parts of waste asbestos, 6 parts of polypropylene fiber, 13 parts of bamboo charcoal powder, 14 parts of coconut shell powder, 10 parts of attapulgite , 9 parts of quartz powder, 15 parts of potassium feldspar, 13 parts of montmorillonite, 17 parts of waste polyethylene foam, 22 parts of Portland cement, 1.4 parts of sodium pyrophosphate, 0.8 parts of penetrating agent, 0.8 parts of water reducing agent, 0.5 parts of foaming agent and 11 parts of water.

[0062] The penetrating agent is fatty alcohol polyoxyethylene ether.

[0063] The water reducer is calcium lignosulfonate.

[0064] The foaming agent is composed of potassium borohydride, phthalic anhydride and ferric nitrate in a mass ratio of 3:1:1.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com