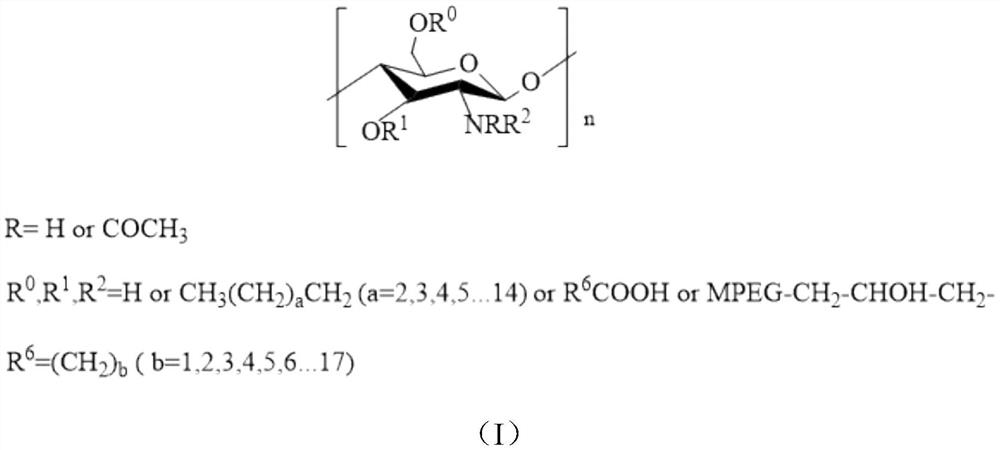

A kind of modified crude oil demulsifier and preparation method thereof

A technology of demulsifier and crude oil, which is applied in chemical dehydration/demulsification, treatment of hydrocarbon oil, petroleum industry, etc. It can solve the problems of secondary pollution and poor environmental friendliness of demulsifier, and achieve neat oil-water interface and strong competitive adsorption Good effect of ability and use safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

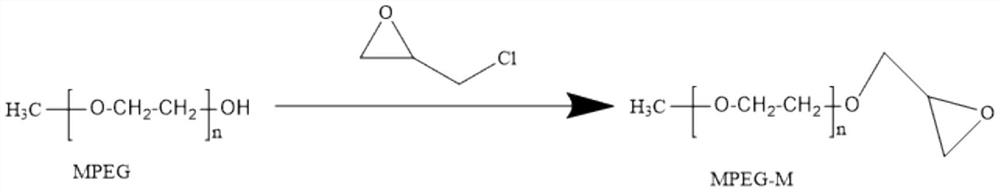

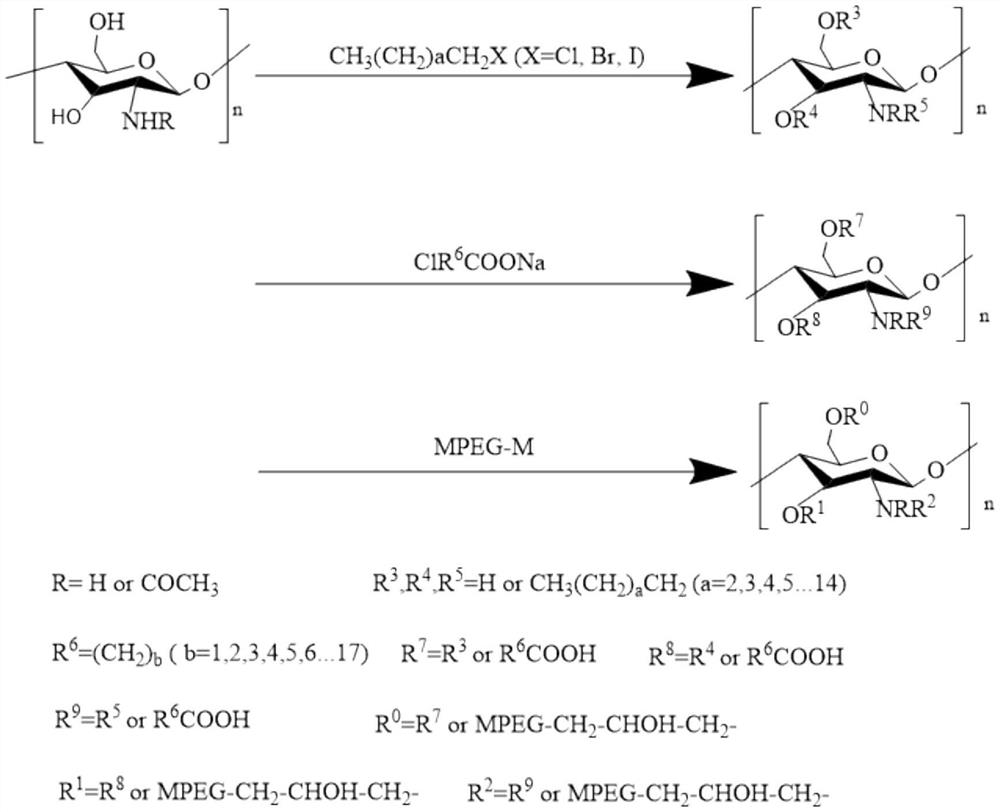

[0042] The preparation of the butyl carboxymethyl chitosan grafted with polyethylene glycol monomethyl ether, concrete steps are as follows:

[0043] (1) Preparation of butyl chitosan: accurately weigh 1.0g chitosan (CS) (M w =179.17kDa, degree of deacetylation >95%, viscosity 100-200mPa·s) in a 250mL three-necked flask, add 12mL isopropanol, 2g potassium hydroxide, and heat up to 40°C under stirring conditions and keep the temperature for 2h to make chitosan Alkalization of sugar. After the alkalization was completed, 3 mL of n-butane bromide was slowly added dropwise at the same reaction temperature, and the reaction was carried out at constant temperature for 6 h. After the reaction was completed, 20 mL of methanol was added to the three-necked flask to wash out the product. Use dilute hydrochloric acid with a mass fraction of 10% to adjust the pH of the system to 7, add 10mL of acetone as a precipitating agent, let it stand for precipitation and then filter, wash the fil...

Embodiment 2

[0048] The preparation of the hexyl carboxymethyl chitosan grafted with polyethylene glycol monomethyl ether, concrete steps are as follows:

[0049] (1) Preparation of hexyl chitosan: accurately weigh 1.0g chitosan (CS) (M w =179.17kDa, degree of deacetylation >95%, viscosity 100-200mPa·s) in a 250mL three-neck flask, add 12mL distilled water, 2g potassium hydroxide, and stir the temperature steadily to 40°C and keep the temperature for 2h to make the chitosan base change. After the alkalization was completed, 3 mL of n-bromohexane was slowly added dropwise at the same reaction temperature, and the reaction was carried out at constant temperature for 6 hours. After the reaction was completed, 20 mL of methanol was added to the three-necked flask to wash out the product. Use dilute hydrochloric acid with a mass fraction of 10% to adjust the pH of the system to 7, add 10 mL of acetone as a precipitating agent, let it sit for precipitation and filter, wash the filter cake thre...

Embodiment 3

[0054] The preparation of the octyl carboxymethyl chitosan grafted with polyethylene glycol monomethyl ether, concrete steps are as follows:

[0055] (1) Preparation of octyl chitosan: accurately weigh 1.0g chitosan (CS) (M w =179.17kDa, degree of deacetylation >95%, viscosity 100-200mPa·s) In a 250mL three-necked flask, add 6mL of distilled water, 12mL of isopropanol, 2g of potassium hydroxide, and steadily raise the temperature to 40°C under stirring and keep the temperature for 2h Alkaline chitosan. After the alkalization was completed, 3 mL of n-octane bromide was slowly added dropwise at the same reaction temperature, and the reaction was carried out at constant temperature for 6 hours. After the reaction was completed, 20 mL of methanol was added to the three-necked flask to wash out the product. Use dilute hydrochloric acid with a mass fraction of 10% to adjust the pH of the system to 7, add 10mL of acetone as a precipitating agent, let it stand for precipitation and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com