Ordered mesoporous carbon encapsulated carbonized metal catalyst for dehydrogenation of alcohol, and preparation method of catalyst

A metal carbide and mesoporous carbon technology, which is applied in catalyst activation/preparation, dehydrogenation preparation, carbon-based compound preparation, etc. High activity and selectivity, solvent-free effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Add F127 and tannic acid to a 30mL stainless steel ball mill tank at a mass ratio of 0.8:1, and add 3 stainless steel balls with a diameter of 1.2cm at the same time, place the ball mill tank on a three-dimensional vibrating ball mill for 30 minutes, and the vibration frequency is 30Hz , then add ammonium molybdate and continue ball milling for 30min, the mass ratio of ammonium molybdate and tannic acid is 1:3, the obtained ball milling mixture is placed in a tube furnace at 800°C for calcination in a nitrogen atmosphere for 2h, and the heating rate is 5°C / min, the ordered mesoporous carbon-encapsulated molybdenum carbide catalyst was obtained.

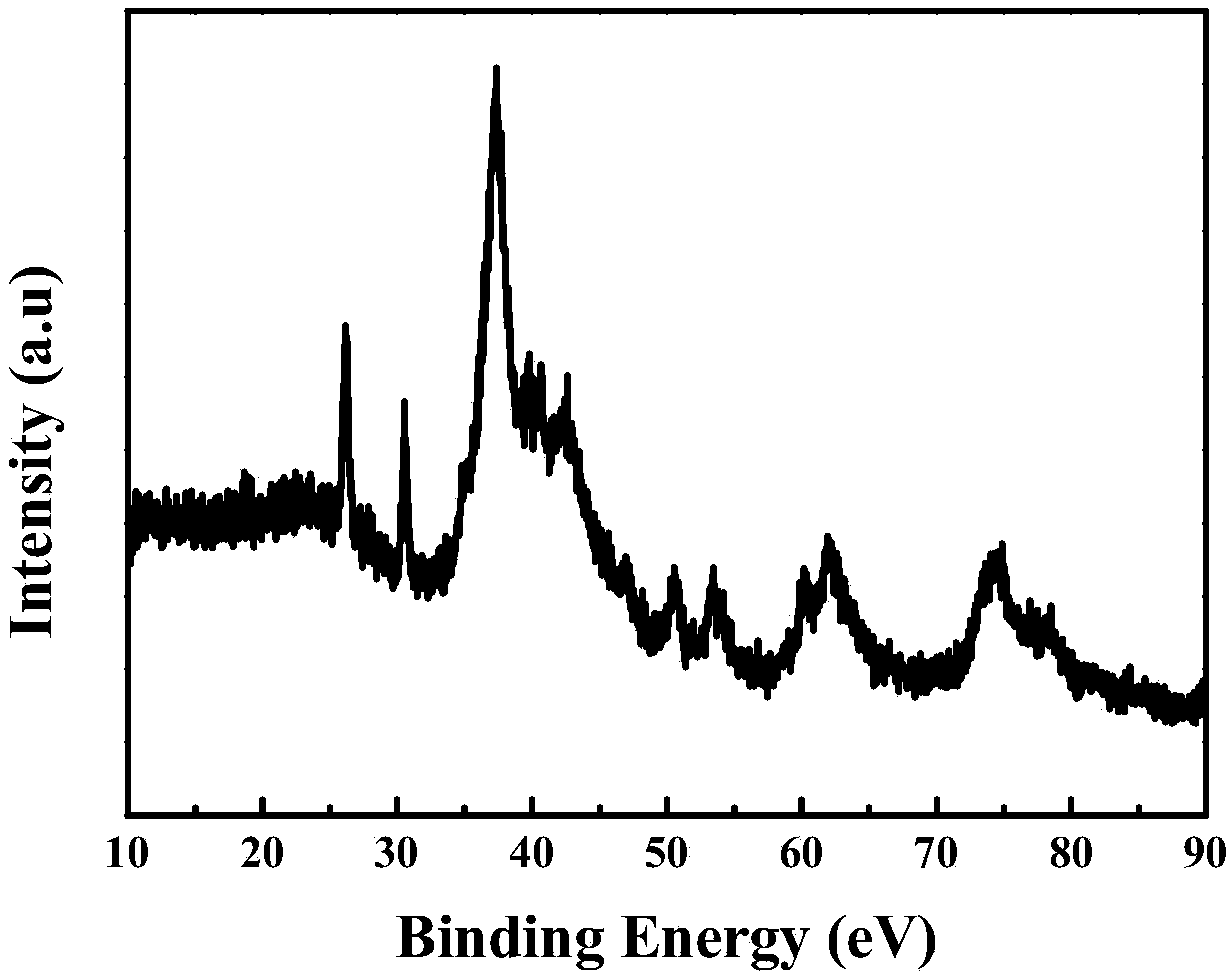

[0016] figure 1 XRD patterns of molybdenum carbide catalysts encapsulated in ordered mesoporous carbon.

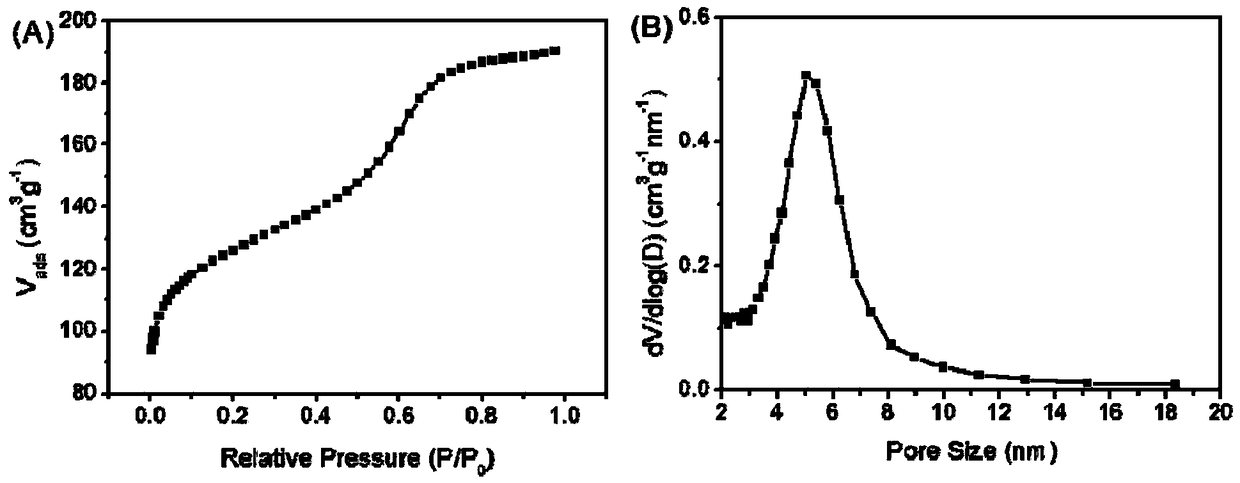

[0017] figure 2 N encapsulation of molybdenum carbide catalysts for ordered mesoporous carbon 2 Adsorption and pore size distribution plots.

Embodiment 2

[0019] Add F127 and tannic acid to a 30mL stainless steel ball mill tank at a mass ratio of 0.8:1, and add 3 stainless steel balls with a diameter of 1.2cm at the same time, place the ball mill tank on a three-dimensional vibrating ball mill for 30 minutes, and the vibration frequency is 30Hz , then add ammonium tungstate to continue ball milling for 30min, the mass ratio of ammonium molybdate and tannic acid is 1:3, put the obtained ball milling mixture in a tube furnace at 900°C for calcination in a nitrogen atmosphere for 3h, the heating rate is 5°C / min, the ordered mesoporous carbon-encapsulated tungsten carbide catalyst was obtained.

Embodiment 3

[0021] Mix benzyl alcohol and DMSO at a mass ratio of 1:5, then add an ordered mesoporous carbon-encapsulated molybdenum carbide catalyst whose mass is 5% of the alcohol mass, and stir for 4 hours at a reaction temperature of 100°C to obtain a mixture containing benzaldehyde products , The conversion and selectivity of the reaction detected by gas chromatography were 98% and 100%, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com