Thymol, and preparation method and pharmaceutical composition thereof

A technology for thymol and cresol, which is applied in the field of organic compound preparation, can solve the problems of high equipment requirements, low selectivity, difficult separation and the like, and achieves the effects of high total yield, mild scheme conditions, and cheap and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040]In the preparation method of thymol provided by the present invention, the first step is: condensation reaction of m-cresol and ethyl acetoacetate to obtain 4,7-dimethylcoumarin. The present invention has no special limitation on the conditions for the condensation reaction to occur. For example, existing solid superacid catalysis and acidic zeolite catalysis can be used, and the reaction can be carried out in a solvent environment or in a solvent-free environment. As a preferred scheme of the present invention, m-cresol and ethyl acetoacetate are reacted at 110-120° C. for 4-6 hours under the action of Lewis acid and mixed solvent to obtain 4,7-dimethylcoumarin, m-cresol and ethyl acetoacetate The ratio of the amount of ethyl acetoacetate is 1:1.0-10, preferably 1:1.0-3.0, and most preferably 1:1.2-2.0. The mass ratio of m-cresol to Lewis acid is 1:0.5-5.0, preferably 1:1.0-4.0, and most preferably 1:1.5-3.0. The Lewis acid is independently aluminum trichloride or tita...

Embodiment 1

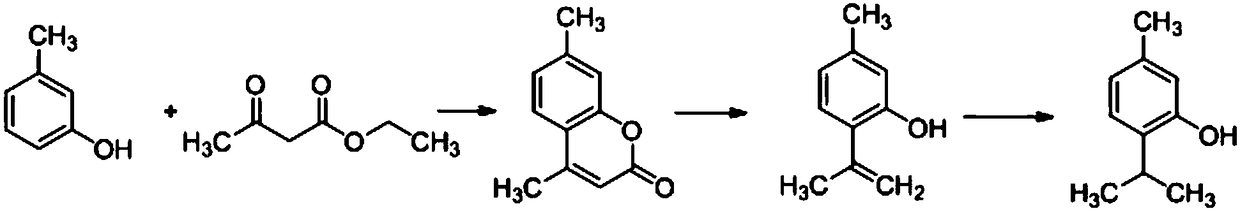

[0056] Prepare thymol according to the following steps, the reaction process is as follows figure 1 Shown:

[0057] Step 1: Dichloromethane (1.2kg) was added into a 5L four-necked flask, and aluminum trichloride (0.94kg) was added to obtain a suspension. Ethyl acetoacetate (0.54kg) was slowly and uniformly added to the reactor; after addition, m-cresol (0.3kg) was added. Add dioxane (0.8kg), slowly raise the temperature to collect dichloromethane to T=110-112°C, stop collecting dichloromethane, and keep warm at 110-120°C for 5 hours. Cool down and add dichloromethane (2.2kg), then add purified water (1.8kg); keep warm at 20-30°C for liquid separation for 30 minutes, and separate the organic phase; add purified water (0.6kg) to the organic phase, stir for 15 minutes, and let stand Separation for 60min. The organic phase was transferred to a still, and concentrated under reduced pressure until there was no distillate; ethanol (0.5 kg) was added, and stirred at 0-5°C for 1 h. ...

Embodiment 2

[0065] Step 1: Pour methylene chloride (6kg) into a glass reactor, add aluminum trichloride (4.7kg) to obtain a suspension. Ethyl acetoacetate (2.7kg) was slowly and uniformly added to the reactor; after addition, m-cresol (1.5kg) was added. Add toluene (4.5kg), slowly raise the temperature to collect dichloromethane to T=110-112°C, stop collecting dichloromethane, and keep warm at 110-120°C for 5 hours. Cool down and add dichloromethane (11kg), then add purified water (9kg); keep warm at 20-30°C for liquid separation for 30 minutes, and separate the organic phase; add purified water (3kg) to the organic phase, stir for 15 minutes, and stand for liquid separation for 60 minutes . The organic phase was transferred to a still, and concentrated under reduced pressure until there was no distillate; ethanol (2.5kg) was added, and stirred at 0-5°C for 1h. Blow out, filter with suction, rinse the filter cake with cold ethanol (1.5kg) (below 10°C). The filter cake is air-dried at 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com