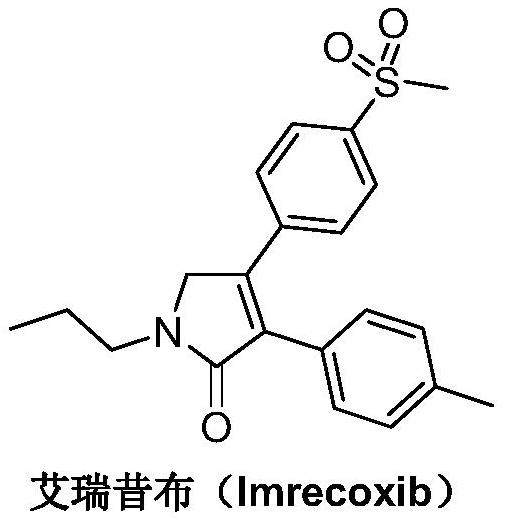

A kind of synthetic method of Erecoxib

A synthesis method and p-methylphenyl technology, applied in the field of erecoxib synthesis, can solve the problems of many impurities and by-products, unfavorable post-processing and purification, and difficulty in meeting the quality requirements of raw materials, and achieve cost reduction, The effect of less impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

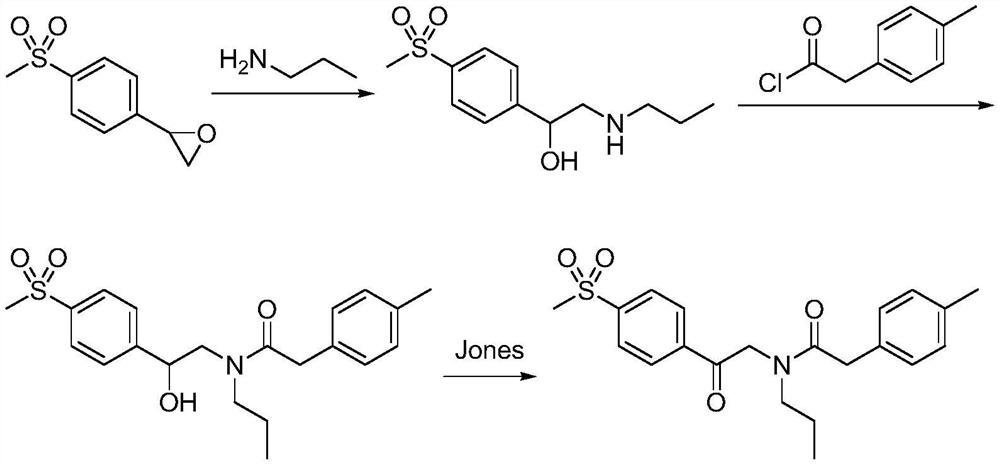

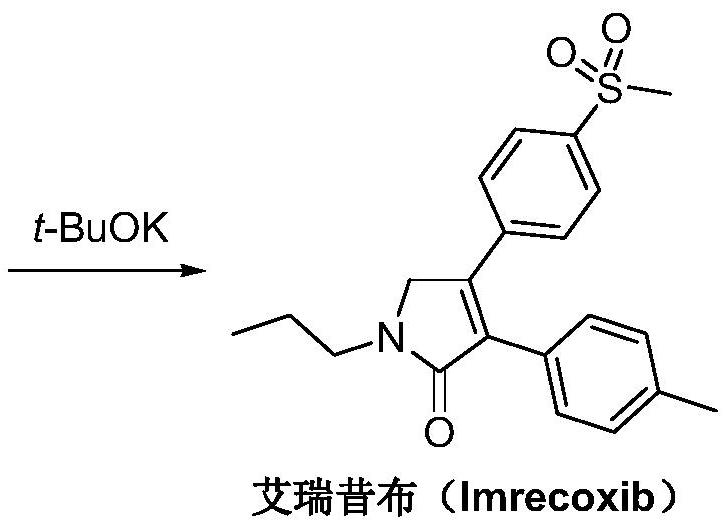

Method used

Image

Examples

Embodiment 1

[0040] A) Synthesis of 3-p-methylphenyl-4-p-methylsulfonylphenylpyrrole-2-carboxylic acid methyl ester:

[0041] (E)-1-p-methylsulfonylphenyl-1-nitro-2-p-tolylethylene (21.0g) was dissolved in isopropanol (300mL), sodium hydroxide (4.0g) was added, stirred and ice-bathed Cool to 5-10°C, add a solution of methyl isocyanoacetate (7.2g) in isopropanol (12mL) dropwise, rise to 30°C and react for 18h until the reaction is complete. After post-treatment, the obtained crude product is recrystallized with ethanol, To obtain methyl 3-p-methylphenyl-4-p-methylsulfonylphenylpyrrole-2-carboxylate, 23.2 g of off-white solid, yield 95%.

[0042] B) Synthesis of 3-p-methylphenyl-4-p-methylsulfonylphenylpyrrole-2-carbaldehyde:

[0043]3-p-methylphenyl-4-p-methylsulfonylphenylpyrrole-2-carboxylic acid methyl ester (23.0g) was dissolved in dichloromethane (350mL), cooled to -78°C, and bis(2-methyl Oxyethoxy) sodium aluminum hydride (13.8g) in n-hexane solution, heat preservation reaction for ...

Embodiment 2

[0049] A) synthesis of 3-p-methylphenyl-4-p-methylsulfonylphenylpyrrole-2-carboxylic acid ethyl ester:

[0050] (E)-1-p-methylsulfonylphenyl-1-nitro-2-p-tolylethylene (12.0g) was dissolved in tetrahydrofuran (180mL), potassium carbonate (9.4g) was added, stirred and cooled to 5 ~10°C, add a solution of ethyl isocyanoacetate (5.6g) in tetrahydrofuran (10mL) dropwise, rise to 35°C and react for 12h until the reaction is complete. Ethylphenyl-4-p-methylsulfonylphenylpyrrole-2-carboxylate, off-white solid 13.5g, yield 93%.

[0051] B) Synthesis of 3-p-methylphenyl-4-p-methylsulfonylphenylpyrrole-2-carbaldehyde:

[0052] 3-p-methylphenyl-4-p-methylsulfonylphenylpyrrole-2-carboxylic acid ethyl ester (13.0g) was dissolved in toluene (180mL), cooled to -78°C, diisobutylaluminum hydride ( 6.3 g) of n-hexane solution, keep it warm for 4 hours until the reaction is complete, add dilute hydrochloric acid dropwise at low temperature to quench the reaction solution, rise to room temperatu...

Embodiment 3

[0058] A) Synthesis of 3-p-methylphenyl-4-p-methylsulfonylphenylpyrrole-2-carboxylic acid methyl ester:

[0059] (E)-1-p-methylsulfonylphenyl-1-nitro-2-p-tolylethylene (5.6g) was dissolved in methanol (100mL), and 1,8-diazabicyclo[5.4.0]deca was added One-carb-7-ene (5.4g), stirred and cooled in an ice bath to 5-10°C, added dropwise a solution of methyl isocyanoacetate (2.6g) in methanol (6mL), raised to 20°C and reacted for 24h until the reaction was complete , after post-treatment, the obtained crude product was recrystallized from ethanol to obtain 3-p-methylphenyl-4-p-methylsulfonylphenylpyrrole-2-carboxylic acid methyl ester, 6.3 g of off-white solid, yield 96%.

[0060] B) Synthesis of 3-p-methylphenyl-4-p-methylsulfonylphenylpyrrole-2-carbaldehyde:

[0061] 3-p-methylphenyl-4-p-methylsulfonylphenylpyrrole-2-carboxylic acid methyl ester (6.2g) was dissolved in chloroform (100mL), cooled to -78°C, diisobutylaluminum hydride ( 3.6 g) of n-hexane solution, heat preservati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com