A kind of epoxy resin fiberglass for four-wheel electric vehicle shell

An epoxy resin, electric vehicle technology, applied in the field of glass fiber reinforced plastic, can solve the problems of not very good, easy to crack, heat resistance, mechanical properties of glass fiber reinforced plastic, heat resistance and flame retardancy are not very good, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

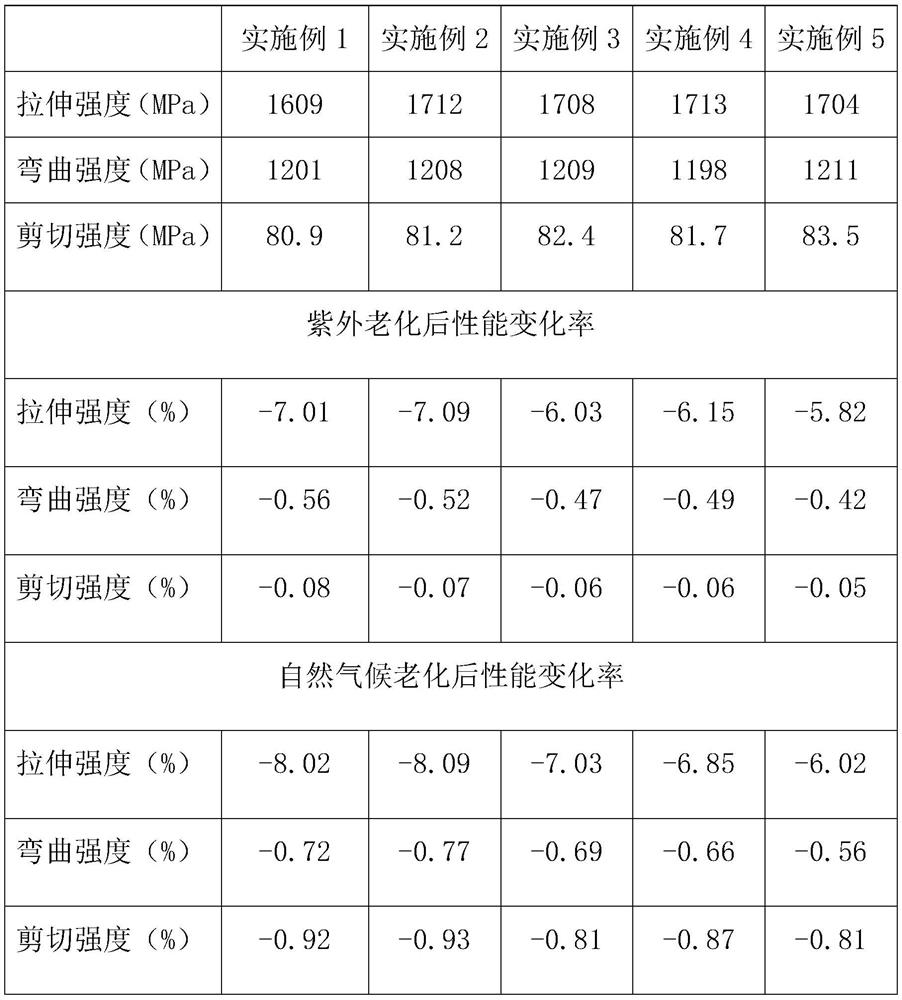

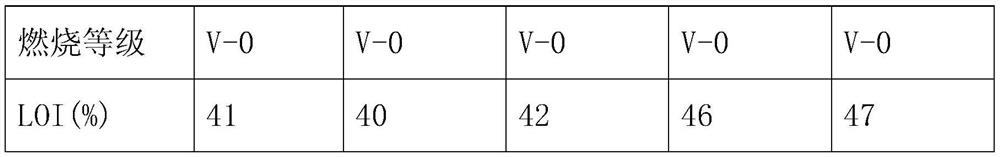

Embodiment 1

[0017] A kind of epoxy resin FRP for four-wheel electric vehicle casing proposed by the present invention, its raw material comprises by weight: 100 parts of epoxy resin, 9 parts of acrylic ester liquid rubber, 2 parts of polyurethane, 11 parts of diluent, methyl chelate 3 parts of acid anhydride, 3 parts of methyl tetrahydrophthalic anhydride, 8 parts of modified glass fiber, 9 parts of calcium carbonate, 2 parts of lithium-based montmorillonite, 3 parts of chromium diboride, 2 parts of silver-loaded calcium phosphate, nano-cellulose crystal 9 parts of whiskers, 3 parts of calcium sulfate whiskers, 3 parts of nano zinc oxide, 2 parts of cerium oxide, 13 parts of flame retardant, 1 part of silane coupling agent, 0.8 parts of zinc stearate, 2 parts of diphenyl dichlorosilane , 3 parts of bisphenol fluorene, 0.1 part of tetraethylammonium hydroxide.

Embodiment 2

[0019] A kind of epoxy resin glass fiber reinforced plastics for four-wheel electric vehicle shell that the present invention proposes, its raw material comprises by weight: 100 parts of epoxy resin, 3 parts of acrylate liquid rubber, 8 parts of polyurethane, 3 parts of diluent, methyl chelate 8 parts of acid anhydride, 1 part of methyl tetrahydrophthalic anhydride, 15 parts of modified glass fiber, 2 parts of calcium carbonate, 7 parts of lithium-based montmorillonite, 1 part of chromium diboride, 11 parts of silver-loaded calcium phosphate, nano-cellulose crystal 2 parts of whiskers, 10 parts of calcium sulfate whiskers, 1 part of nano zinc oxide, 9 parts of cerium oxide, 8 parts of flame retardant, 2 parts of silane coupling agent, 0.1 part of zinc stearate, 5 parts of diphenyl dichlorosilane , 1 part of bisphenol fluorene, 0.25 part of tetraethylammonium hydroxide.

Embodiment 3

[0021] A kind of epoxy resin FRP for four-wheel electric vehicle casing proposed by the present invention, its raw material comprises by weight: 100 parts of epoxy resin, 8 parts of acrylate liquid rubber, 3 parts of polyurethane, 10 parts of diluent, methyl lyceate 4 parts of acid anhydride, 2.8 parts of methyl tetrahydrophthalic anhydride, 10 parts of modified glass fiber, 8 parts of calcium carbonate, 3 parts of lithium-based montmorillonite, 2.7 parts of chromium diboride, 5 parts of silver-loaded calcium phosphate, nano-cellulose crystal 8 parts of whiskers, 4 parts of calcium sulfate whiskers, 2.8 parts of nano zinc oxide, 4 parts of cerium oxide, 12 parts of flame retardant, 1.2 parts of silane coupling agent, 0.7 parts of zinc stearate, 3 parts of diphenyl dichlorosilane , 2.5 parts of bisphenol fluorene, 0.13 parts of tetraethylammonium hydroxide;

[0022] Wherein, the diluent is a mixture of cresyl glycidyl ether and polypropylene glycol diglycidyl ether, and the wei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com