An underground cross-linked resin plugging agent prepared by seawater and its application

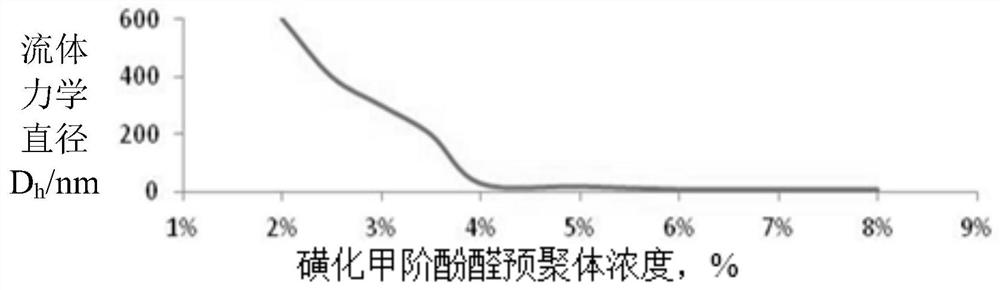

An underground cross-linking and plugging agent technology, which is applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of unstable flocculation and precipitation of prepolymers, lack of intermolecular electrostatic repulsion, and inability to solidify and plug.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

[0086] In this experimental example, a sulfonated modified substance was synthesized: sodium 2-hydroxy-3-phenylene ether propanesulfonate, the process is summarized as follows:

[0087] Add 3.2 mol of epichlorohydrin, 0.4 mol of phenol and 0.84 mol of anhydrous potassium carbonate into a four-neck flask equipped with a thermometer, a reflux condenser, and a magnetic stirrer, and react at high temperature for 4 hours under stirring. After completion of the reaction, cool to room temperature, filter out inorganic salts, and wash with an appropriate amount of epichlorohydrin, evaporate unreacted epichlorohydrin, and collect 120-123 ° C (1.466kpa) cuts by vacuum distillation to obtain the intermediate product (I ). Yield 73.8%, shading rate 1.5306 (20°C). Add 200ml of chloroform to the intermediate product (I), stir at room temperature and slowly add 0.88mol of 36% hydrochloric acid dropwise, react for 5h and then separate the liquids, and distill off the chloroform after the low...

experiment example 2

[0090] In this experimental example, a sulfonated modified substance was synthesized: sodium m-hydroxy-phenylene ether propanesulfonate. The process is summarized as follows:

[0091] Add 0.4mol resorcinol, 30ml dioxane, 0.1mol sodium phosphate and water into a four-necked flask equipped with a thermometer, reflux condenser, and magnetic stirrer. After the temperature rises to 70°C, add 0.5mol epoxy chlorine dropwise Propane, after reacting for 2 hours, a colorless aqueous solution was obtained, and the generation rate of chlorine in the product was measured by sampling. The solution was treated with a rotary evaporator for 30 min to remove unreacted epichlorohydrin to obtain an aqueous solution of the intermediate product. The temperature was raised to 80°C, and 0.5 mol of sodium bisulfite / saturated sodium sulfite solution was slowly added dropwise, kept for 2 hours and then cooled to room temperature to obtain a light yellow viscous substance. The solid was repeatedly recry...

experiment example 3

[0093] In this experimental example, a sulfonated modified substance was synthesized: sodium urea-containing propanesulfonate. The process is summarized as follows:

[0094] Add 0.4mol urea, 0.1mol sodium phosphate and water into a four-neck flask equipped with a thermometer, a reflux condenser, and a magnetic stirrer. After the temperature rises to 80°C, add 0.5mol epichlorohydrin dropwise and react for 2 hours to obtain a colorless aqueous solution. , Sampling to measure the formation rate of chlorine in the product. The solution was treated with a rotary evaporator for 30 min to remove unreacted epichlorohydrin to obtain an aqueous solution of the intermediate product. The temperature was raised to 80°C, and 0.5 mol of sodium bisulfite / saturated sodium sulfite solution was slowly added dropwise, kept for 2 hours and then cooled to room temperature to obtain a light yellow viscous substance. The solid was repeatedly recrystallized in deionized water, extracted with ethanol,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com