Composite nano-propylene pigment and preparation method thereof

A kind of acrylic paint, nanotechnology, applied in the field of pigments, can solve the problems of easy cracking, mildew, fading and other problems of pigments, and achieve the effect of ensuring long-term durability, not easy to mold, and good color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

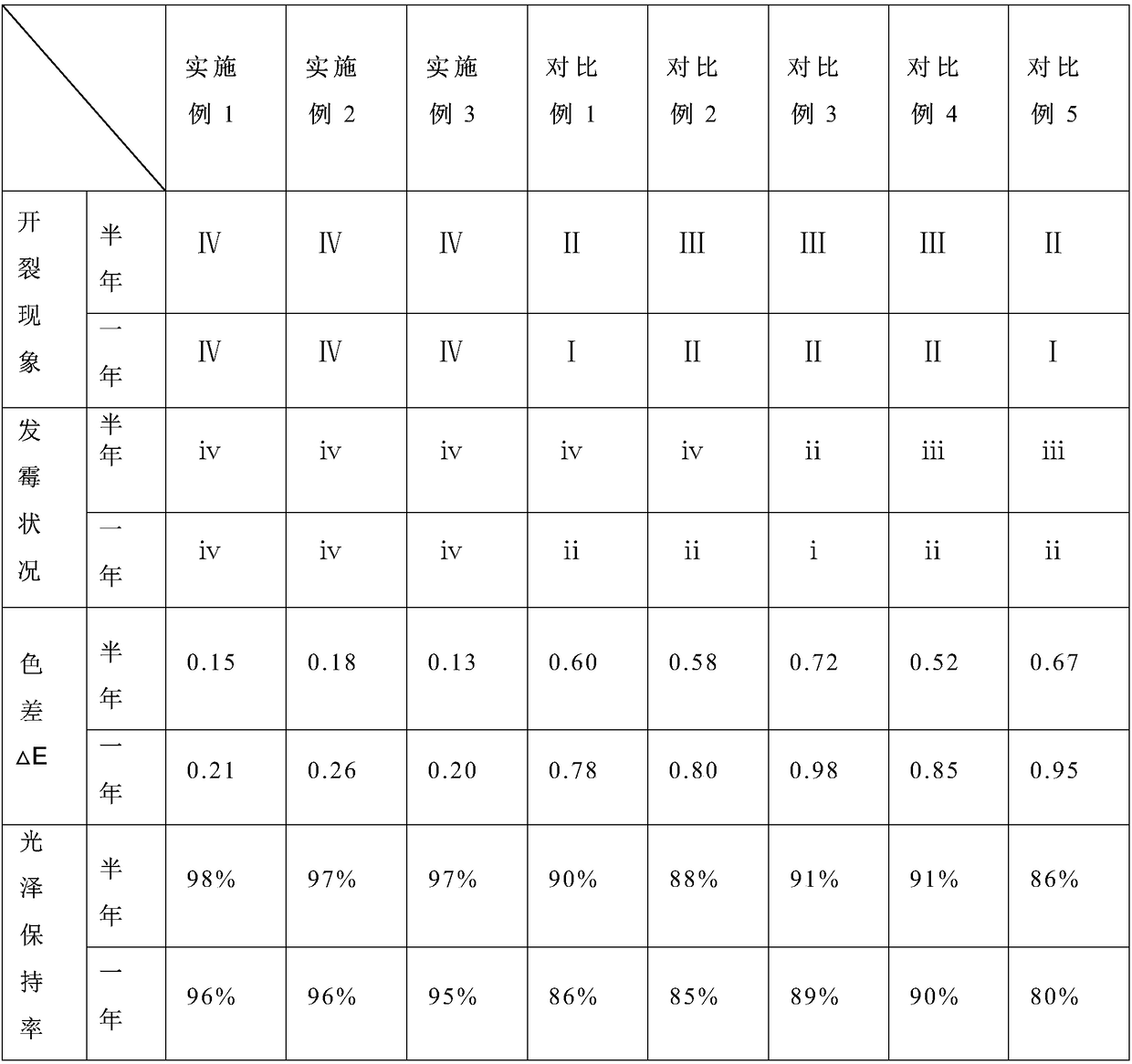

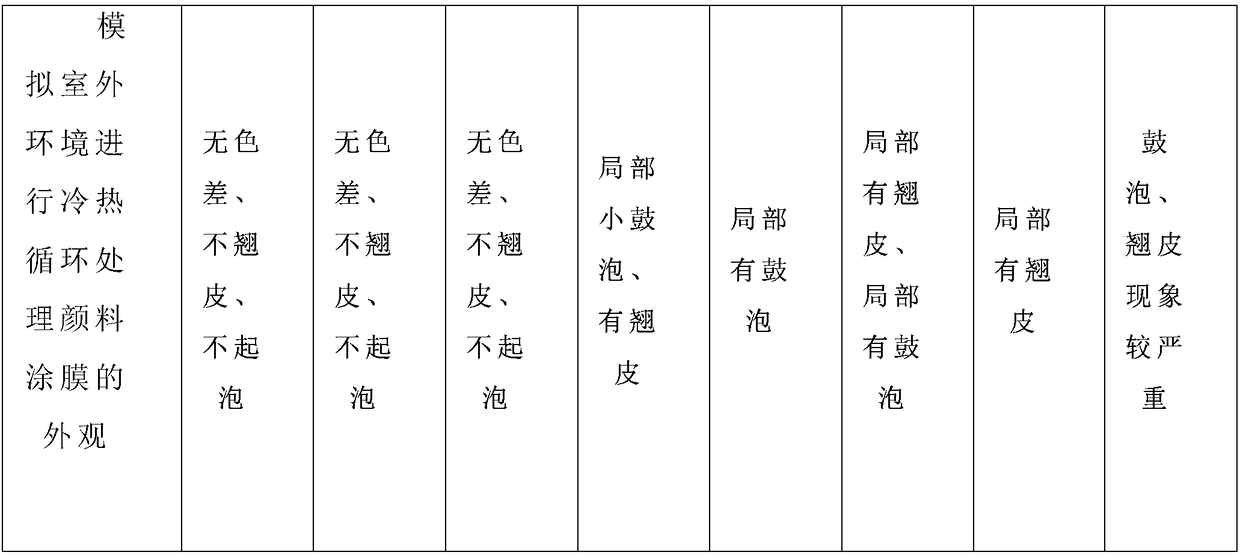

Examples

Embodiment 1

[0028] This embodiment provides a composite nano propylene pigment. The raw material formula includes: 50 parts of acrylate emulsion, 10 parts of nano calcium oxide, 3 parts of nano zinc oxide, 3 parts of nano titanium dioxide, 4 parts of nano calcium carbonate, and polyether modified 0.05 parts of polydimethylsiloxane, 0.05 parts of N-(β-aminoethyl)-γ-aminopropylmethyldimethoxysilane, 0.4 parts of aminopropylamine dioleate, 2 dodecyl alcohol esters Parts, 2 parts of triethanolamine, 2 parts of gum arabic, 1 part of ethylene glycol, 0.5 part of anti-mold fungicide, 20 parts of Phthalocyanine Green G and 2 parts of water.

[0029] The preparation method includes: weighing the above-mentioned raw materials according to the formula ratio, and combining the acrylate emulsion, the nano calcium oxide, the nano zinc oxide, the nano titanium dioxide, the nano calcium carbonate, the water and the Polyether modified polydimethylsiloxane, N-(β-aminoethyl)-γ-aminopropylmethyldimethoxysilane,...

Embodiment 2

[0031] This embodiment provides a composite nano propylene pigment. The raw material formula includes: 45 parts of acrylate emulsion, 10 parts of nano calcium oxide, 4 parts of nano zinc oxide, 4 parts of nano titanium dioxide, 4 parts of nano calcium carbonate, polyether modified 0.05 parts of polydimethylsiloxane, 0.1 parts of N-(β-aminoethyl)-γ-aminopropylmethyldiethoxysilane, 0.55 parts of aminopropylamine dioleate, 3 dodecyl alcohol esters Parts, 2 parts of triethanolamine, 2 parts of gum arabic, 2 parts of ethylene glycol, 0.5 parts of anti-mold fungicide, 20 parts of Phthalocyanine Green G and 3.3 parts of water.

[0032] The preparation method includes: weighing the above-mentioned raw materials according to the formula ratio, and combining the acrylate emulsion, the nano calcium oxide, the nano zinc oxide, the nano titanium dioxide, the nano calcium carbonate, the water and the Polyether modified polydimethylsiloxane, N-(β-aminoethyl)-γ-aminopropylmethyldiethoxysilane, a...

Embodiment 3

[0034] This embodiment provides a composite nano propylene pigment. The raw material formula includes: 53 parts of acrylate emulsion, 9 parts of nano calcium oxide, 3 parts of nano zinc oxide, 4 parts of nano titanium dioxide, 4 parts of nano calcium carbonate, polyether modified 0.07 parts of polydimethylsiloxane, 0.07 parts of N-(β-aminoethyl)-γ-aminopropylmethyldimethoxysilane, 0.86 parts of aminopropylamine dioleate, 2 dodecyl alcohol esters Parts, 2 parts of triethanolamine, 1 part of gum arabic, 1 part of ethylene glycol, 0.5 parts of anti-mold fungicide, 18 parts of Phthalocyanine Green G and 1.5 parts of water.

[0035] The preparation method includes: weighing the above-mentioned raw materials according to the formula ratio, and combining the acrylate emulsion, the nano calcium oxide, the nano zinc oxide, the nano titanium dioxide, the nano calcium carbonate, the water and the Polyether modified polydimethylsiloxane, N-(β-aminoethyl)-γ-aminopropylmethyldimethoxysilane, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com