Probiotics microcapsule as well as preparation method and application thereof

A technology of probiotics and microcapsules, applied in application, animal feed, additional food elements, etc., can solve the problems of loss of coating protection, difficulty in forming sphericity, and damage to probiotic cells, so as to promote colonization in the intestinal tract, Avoid decomposition, high mechanical strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

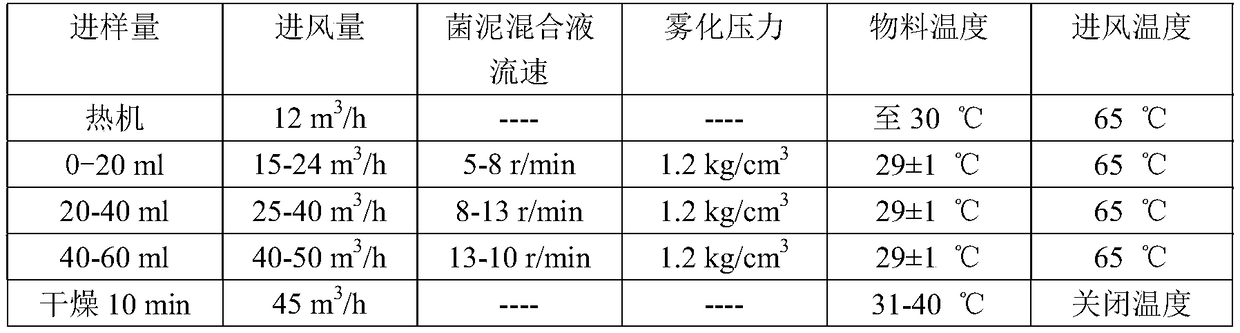

[0045] The preparation of embodiment 1 plantarum lactobacillus (single bacterium) microcapsule

[0046] 1) Activation and proliferation of bacteria:

[0047] Inoculate Lactobacillus plantarum JCM-1149 (derived from the Japanese strain preserved in the Microbiology Laboratory of the Agricultural College of China Agricultural University) into MRS liquid medium for three generations of activation culture, and use a tube centrifuge (above 10000r / min) to centrifuge for 10-15min. Collect the slime.

[0048] 2) Prepare the bacteria slime mixture:

[0049] Take 15ml of bacteria slime and add 45ml of 20% skimmed milk powder aqueous solution (bacteria slime: 20% skimmed milk powder solution = 1:3), mix well, and obtain the bacteria slime mixture with protective agent added.

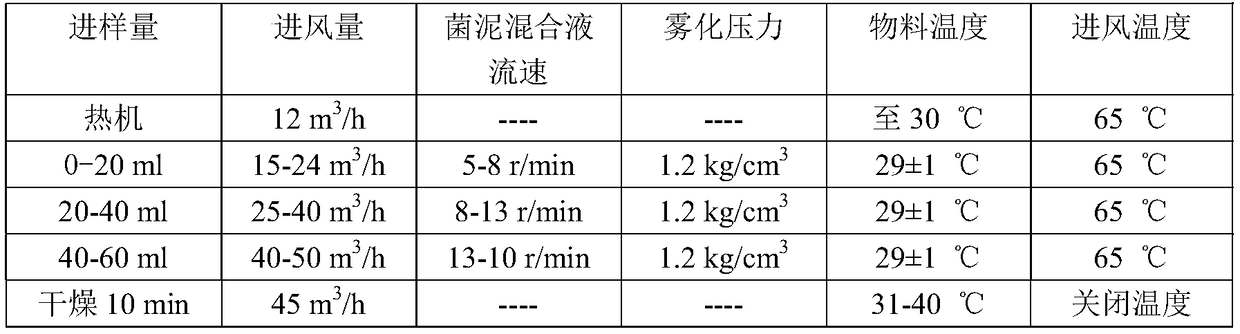

[0050] 3) Granulation:

[0051] Fully mix microcrystalline cellulose blank core and sodium alginate as a matrix (60g microcrystalline cellulose and 5.4g sodium alginate are fully mixed), add 60ml of fungus slime...

Embodiment 2

[0068] The preparation of embodiment 2 composite lactic acid bacteria (composite bacteria) microcapsules

[0069] 1) Activation and proliferation of bacteria:

[0070] The compound lactic acid bacteria are mainly composed of Lactobacillus, Lactococcus and Bacillus (provided by the Microbiology Laboratory of the Agricultural College of China Agricultural University), inoculated in the MRS liquid medium for activation and cultivation for three generations, using a tubular centrifuge (above 10000r / min ) by centrifugation for 10-15min to collect the sludge.

[0071] 2) Prepare the bacteria slime mixture:

[0072] Take 1 kg of the above-mentioned processed fungus slime and add 3 kg of 20% skim milk powder aqueous solution (sludge: 20% skim milk powder solution = 1:3), and mix well to obtain the fungus slime mixture with protective agent added.

[0073] 3) Granulation:

[0074] The microcrystalline cellulose blank ball core and sodium alginate were fully mixed as a matrix for gra...

Embodiment 3

[0093] The performance test of embodiment 3 microcapsule products

[0094] The existing reports all use in vitro simulation of the gastrointestinal tract environment to test whether the coated bacteria can tolerate the environment of gastric acid and bile salts, and finally target release. However, this study adopts the method of in vivo verification to truly evaluate the biological process experienced by lactic acid bacteria when they play a probiotic role. The specific implementation is as follows:

[0095] For the test, 4 three-parity Holstein dry cows with good body condition and similar body weight were selected in the Zhongdi Breeding Stock Cow Science and Technology Park in Shunyi District, Beijing. Permanent rumen fistula and duodenal fistula were installed for rumen and duodenum Collection of contents. After one month of postoperative care, the animal body returned to a normal state for experimentation.

[0096] The experiment was divided into three phases, each for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com