A self-assembled collagen-stimulated microsphere with a natural shell-core structure and its preparation method

A nuclear structure and self-assembly technology, applied in tissue regeneration, prosthesis, medical science, etc., can solve the problems of reducing the initial high molecular weight HA, reducing the viscosity of high molecular weight HA, etc., to solve the problem of high viscosity, reduce viscosity, and good application foreground effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Sodium hyaluronate (HA) dry powder with a molecular weight of 1.3 million Daltons was weighed, dissolved in a phosphate buffered saline solution (PBS) with a pH of 7.2, and fully dissolved to prepare a 1.2 wt% HA solution. Weigh ε-polylysine dry powder and add it into HA solution, the molar ratio of ε-polylysine to HA is 1:1, stir well to form emulsion. Add the formed emulsion into the mixed solution of liquid paraffin and Span80, the mass ratio of emulsion: liquid paraffin: Span80 is 1:0.1:10, and stir at 800 rpm for 2 hours after adding. Then add the mixed solution of ε-polylysine and 4-methylmorpholine hydrochloride (DMTMM) in the emulsification system, ε-polylysine: DMTMM: the mol ratio of the HA in the system is 0.5:0.2: 1. Continue stirring for 18 hours to allow the microspheres to settle. The obtained precipitate was suction filtered to remove the oil phase, washed with acetone, and sieved for particle size.

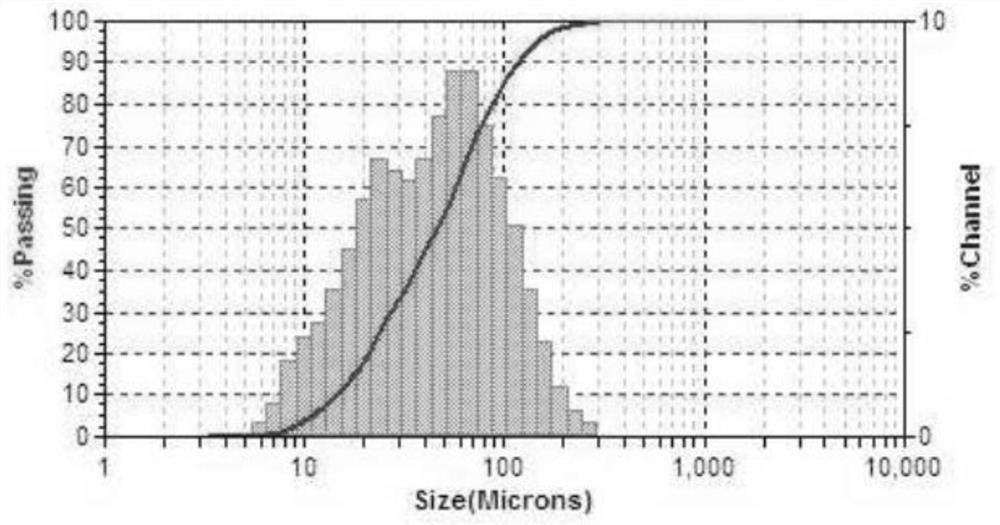

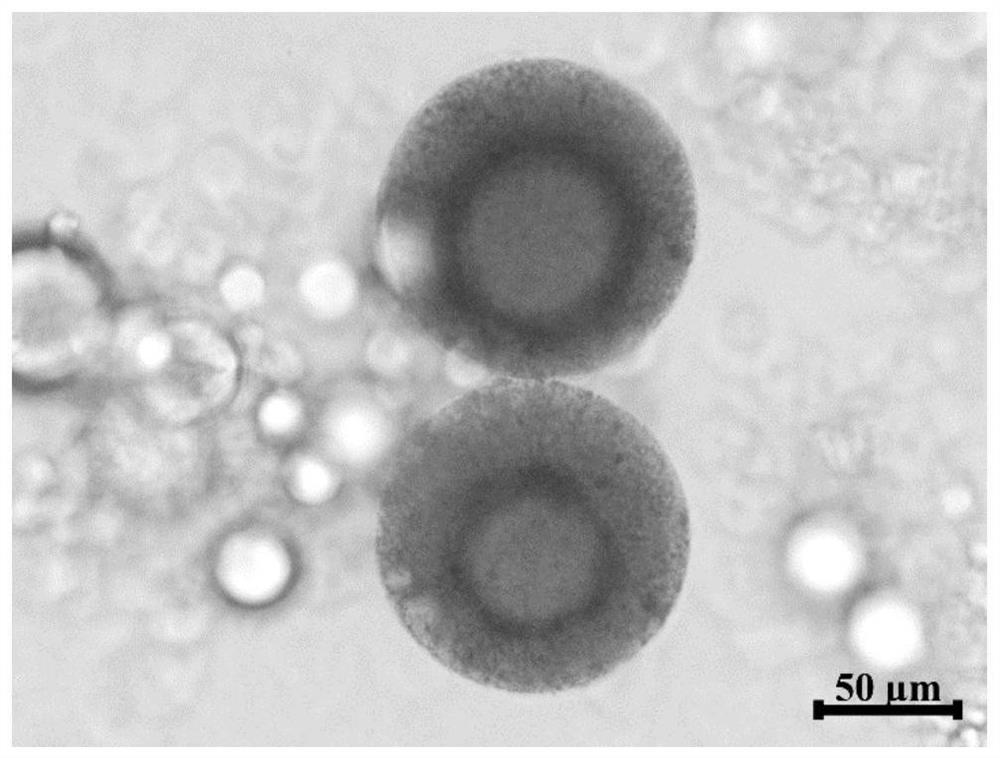

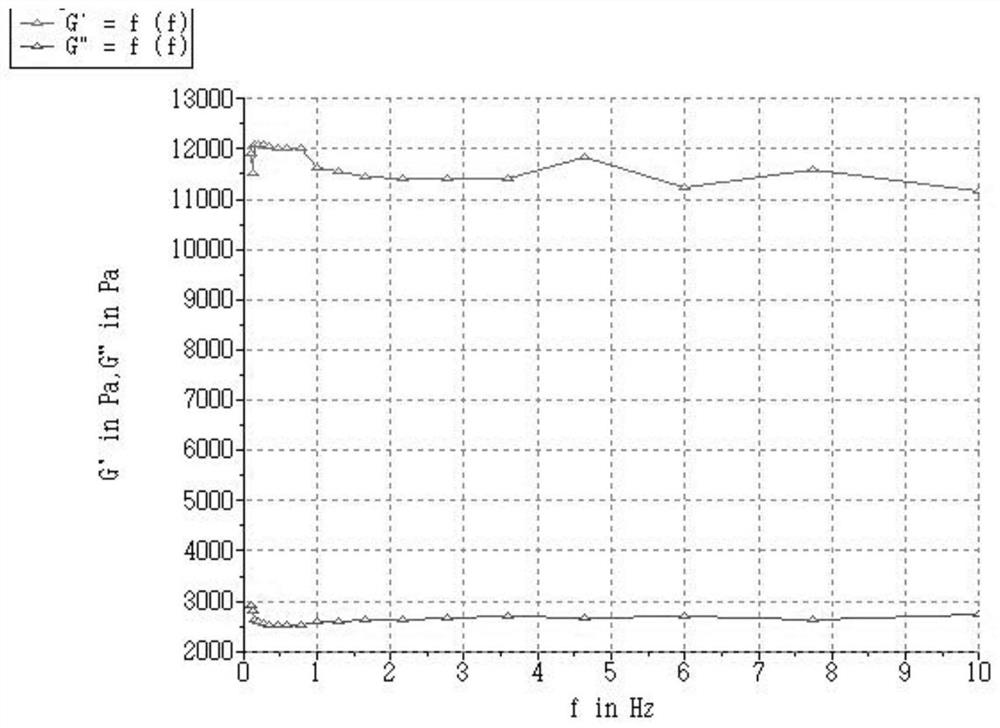

[0033] The particle size and particle size distribu...

Embodiment 2

[0035] Sodium hyaluronate (HA) dry powder with a molecular weight of 1 million Daltons was weighed, dissolved in a phosphate buffered saline solution (PBS) with a pH of 7.2, and fully dissolved to prepare a 1.5 wt% HA solution. Weigh ε-polylysine dry powder and add it into HA solution, the molar ratio of ε-polylysine to HA is 1.3:1, stir well to form emulsion. Add eosin dye dropwise to the emulsion and mix well. Add the formed emulsion to the mixed solution of liquid paraffin and Span80, the mass ratio of emulsion: liquid paraffin: Span80 is 2:0.1:10, and stir at 600 rpm for 1 hour after adding. Then add the mixed solution of ε-polylysine and 4-methylmorpholine hydrochloride (DMTMM) to the emulsification system, drop toluidine blue dye in the mixed solution, ε-polylysine: DMTMM: in the system The molar ratio of HA was 1:0.2:1 and stirring was continued for 24 h to allow the microspheres to settle. The resulting precipitate was filtered off with suction to remove the oily pha...

Embodiment 3

[0038] Sodium hyaluronate (HA) dry powder with a molecular weight of 1.5 million Daltons was weighed, dissolved in 0.9 wt% sodium chloride solution, fully dissolved, and prepared into a 1.8 wt% HA solution. Weigh ε-polylysine dry powder and add it into HA solution, the molar ratio of ε-polylysine to HA is 0.8:1, stir well to form emulsion. Add the formed emulsion into the mixed solution of silicone oil and Span80, the mass ratio of emulsion: silicone oil: Span80 is 2:0.4:10, and stir at 800 rpm for 2 hours after adding. Then add the mixed solution of ε-polylysine and 4-methylmorpholine hydrochloride (DMTMM) in the emulsification system, ε-polylysine: DMTMM: the mol ratio of the HA in the system is 2:1: 1. Continue stirring for 24 hours to allow the microspheres to settle. The obtained precipitate was suction filtered to remove the oil phase, washed with acetone, and sieved for particle size. Then soak the obtained microspheres in 0.9wt% sodium chloride solution for 24 hours,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com