Method for improving anaerobic fermentation efficiency of mushroom residue by white rot fungus pretreatment technology

A white-rot fungus and anaerobic fermentation technology, applied in the field of organic solid waste recycling, can solve the problems of lower anaerobic digestion efficiency and hinder the use of substrates by microorganisms, and achieve good application prospects, high product added value, and raw material sources wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

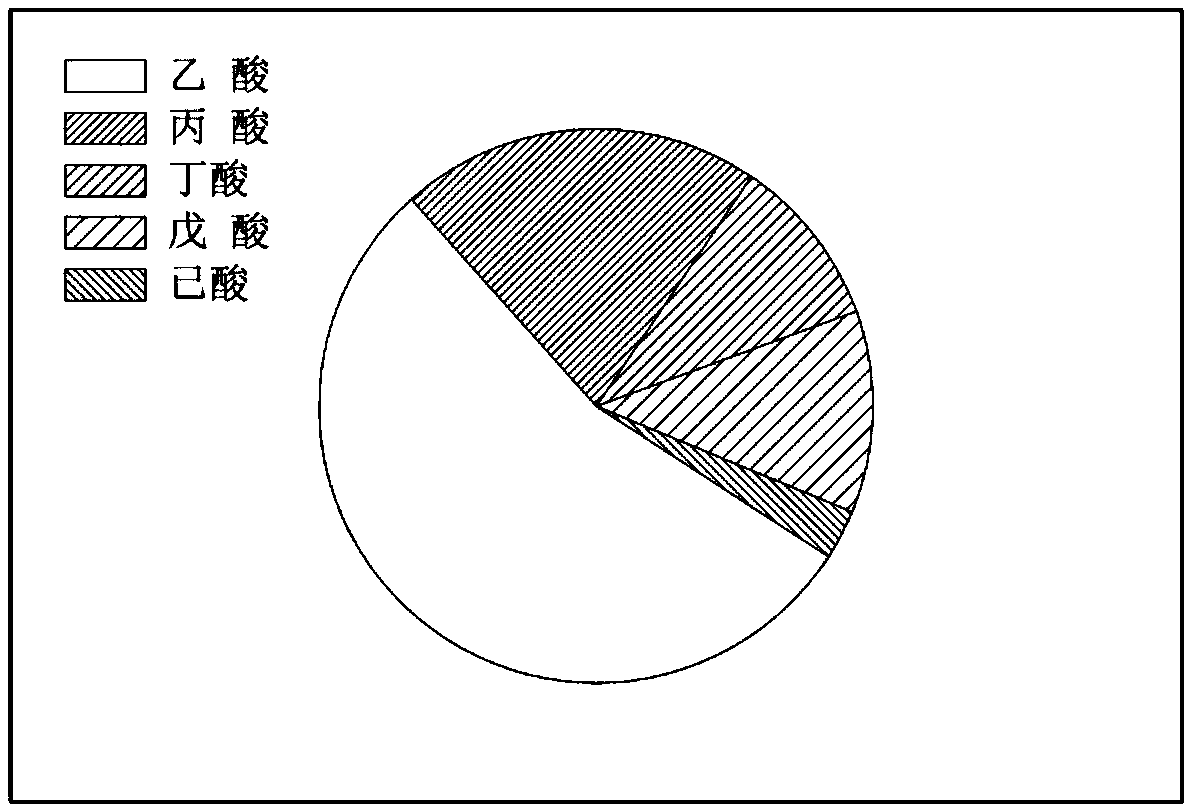

Image

Examples

Embodiment 1

[0021] (1) Take a certain amount of mushroom slag from a certain mushroom factory, whose cellulose content is 12.3%, hemicellulose content is 8.3%, and lignin content is 21.7%, and it is dried in an oven at 60°C for 48 hours, then mechanically pulverized, sieved, and granulated. The diameter is 2.5-1.0cm, and the sieved mushroom dregs are sterilized at 121°C for 30 minutes for subsequent pretreatment;

[0022] (2) Under aseptic and room temperature conditions, Pleurotus Sajor Caju (MES 03464) was inoculated into a reactor containing sterilized mushroom dregs at a mass ratio of 0.1, and the inoculation volume accounted for about 1 / 3 of the entire reactor. Cultivate for 6 weeks under aerobic conditions at 25°C and 75% humidity.

[0023] (3) get the mushroom dregs that obtain in step (2) and put into fermenter, add distilled water and be configured into the mixed solution that solid content rate is 15%; Add inoculated sludge in mixed solution, mixed solution volume and inoculated...

Embodiment 2

[0026] (1) Take a certain amount of mushroom dregs from a certain mushroom factory, whose cellulose content is 17.5%, hemicellulose content is 6.8%, and lignin content is 24.7%, and it is dried in an oven at 60°C for 48 hours, then mechanically crushed, sieved, and granulated. The diameter is 3.0-1.8cm, and the sieved mushroom dregs are sterilized at 121°C for 30 minutes for subsequent pretreatment;

[0027] (2) Under aseptic and room temperature conditions, Pleurotus Sajor Caju (MES 03464) was inoculated into a reactor containing sterilized mushroom dregs at a mass ratio of 0.1, and the inoculation volume accounted for about 1 / 3 of the entire reactor. Cultivate for 6 weeks under aerobic conditions at 25°C and 75% humidity.

[0028] (3) get the mushroom dregs that obtain in step (2) and put into fermenter, add distilled water and be configured into the mixed solution that solid content rate is 12%; Add inoculated sludge in mixed solution, mixed solution volume and inoculated s...

Embodiment 3

[0031] (1) Take a certain amount of mushroom dregs from a certain mushroom factory, whose cellulose content is 15.2%, hemicellulose content is 8.1%, and lignin content is 19.3%, and it is dried in an oven at 60°C for 48 hours, then mechanically crushed, sieved, and granulated. The diameter is 2.7-1.6cm, and the sifted mushroom dregs are sterilized at 121°C for 30 minutes for subsequent pretreatment;

[0032] (2) Under aseptic and room temperature conditions, Pleurotus Sajor Caju (MES 03464) was inoculated into a reactor containing sterilized mushroom dregs at a mass ratio of 0.1, and the inoculation volume accounted for about 1 / 3 of the entire reactor. Cultivate for 6 weeks under aerobic conditions at 25°C and 75% humidity.

[0033] (3) get the mushroom dregs that obtain in step (2) and put into fermenter, add distilled water and be configured into the mixed solution that solid content rate is 15%; Add inoculated sludge in mixed solution, mixed solution volume and inoculated s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com