Glutamate oxidase mutant, nucleic acid molecule, applications of glutamate oxidase mutant, and method for preparing ketoglutaric acid

A glutamate oxidase and nucleic acid molecule technology, which is applied in the field of ketoglutarate preparation, can solve the problems of insufficient L-glutamate oxidase catalytic properties, long production cycle, low conversion rate and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Construction of Genetically Engineered Bacteria Expressing Glutamate Oxidase Mutants

[0035] (1) On the basis of the wild sequence of Streptomyces glutamate oxidase, artificially design, the designed gene sequence is shown in SEQ ID NO.2, and the amino acid sequence of the glutamate oxidase mutant encoded by it is as follows Shown in SEQ ID NO.1. The above-mentioned gene sequence is synthesized by the method of whole gene synthesis.

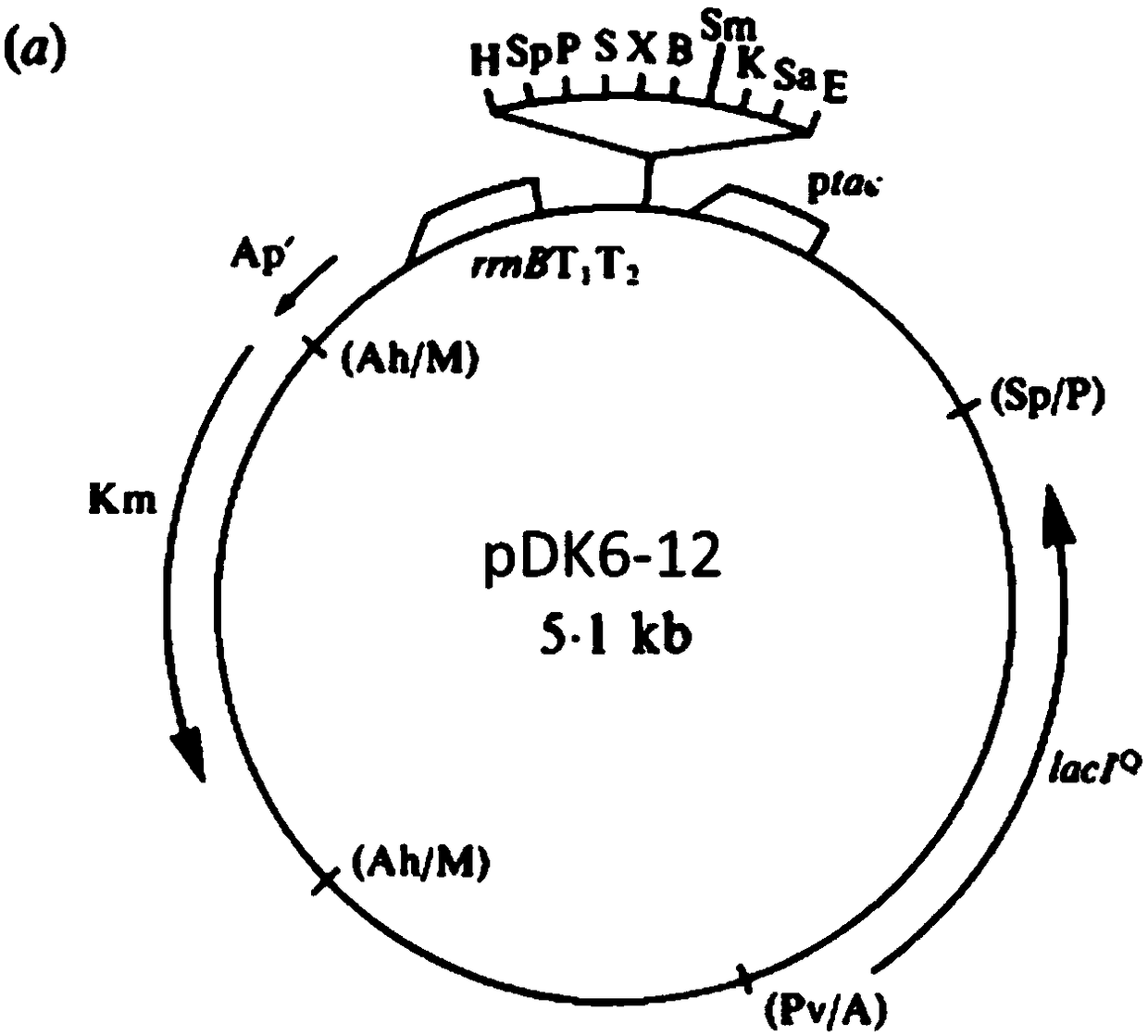

[0036] (2) The synthetic gene sequence was cloned into the pDK6 plasmid through EcoR1 and Pst1 2 restriction sites, and the above-constructed plasmid was transferred into Escherichia coli DH5α competent cells, and after positive transformants were selected and identified by sequencing, the recombinant expression vector was obtained , named pDK6-12 plasmid (see figure 1 ).

[0037] (3) The recombinant expression vector pDK6-12 plasmid was transformed into Escherichia coli BL21(DE3) strain to obtain genetically engineered bacteria capabl...

Embodiment 2

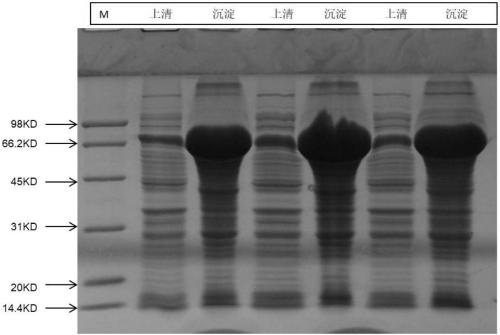

[0039] Preparation of glutamate oxidase mutants

[0040] (1) Streak the genetically engineered bacteria used to express the Streptomyces glutamic acid oxidase mutant prepared in Example 1 on the kanamycin-resistant LB solid medium, and cultivate it in a biochemical incubator at 37°C Overnight, select a larger colony and inoculate it into LB liquid medium containing kanamycin resistance, and culture it on a shaker at 37°C 220rpm for 6-8h, or at 30°C 200rpm overnight to obtain a primary seed culture solution.

[0041] (2) Inoculate the primary seed culture liquid into the TB liquid medium containing kanamycin resistance according to the inoculation amount of 1%, and cultivate it in a shaker at 37° C. 220 rpm for 4 to 6 hours until the bacterial liquid is turbid by visual inspection, and obtain Secondary seed culture fluid.

[0042] (3) According to the inoculum amount of 1%, the secondary seeds are inoculated into the fermenter for cultivation. Initial control: 37°C aeration a...

experiment example

[0047] Experiments using the above bacteria to catalyze the formation of ketoglutaric acid from glutamic acid

[0048] Enzyme reaction: the reaction system is 8 liters

[0049] 1. Weigh 200 grams of frozen bacteria (approximately 2.5% of the transformation system), 80 mL of 400,000 units of catalase, dilute to 5 liters of tap water (pH is approximately 6.4), keep warm at 35 ° C, 400 rpm, 1 vvm, Tank pressure 0.05Mpa.

[0050] 2. Take by weighing 800 grams of sodium glutamate monohydrate (about 10% of the conversion system), dissolve it with 3 liters of tap water, add the conversion system with a peristaltic pump flow, and the flow rate is 1.2 liters / hour. During the period, the pH was controlled at about 6.5 with 1% hydrochloric acid. Samples were taken every hour to detect ketoglutaric acid, and the conversion was completed in about 3 hours.

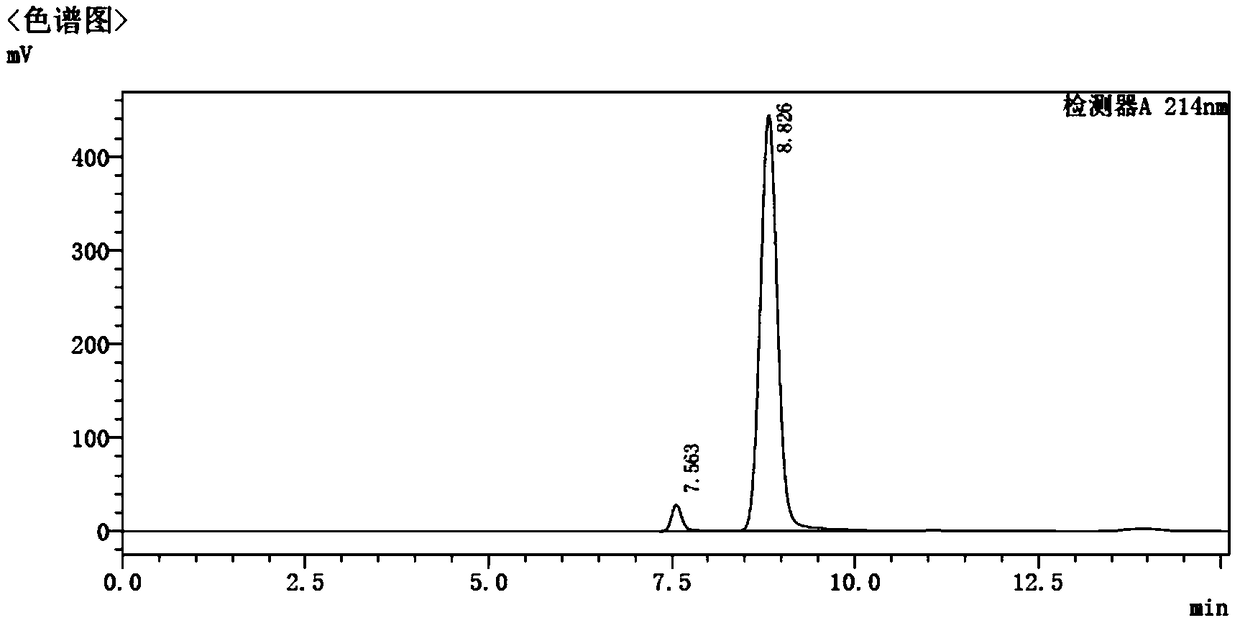

[0051] Ketoglutarate detection

[0052] 1. Standard configuration: Accurately weigh 0.008 g of ketoglutaric acid standard (above 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com