Dialysis membrane for hemodialyzer and preparation method thereof

A technology of hemodialysis and dialysis membrane, which is applied in the field of medical devices, can solve the problems of biocompatibility, blood description, hydrophilicity, smoothness and low removal rate, and achieve good surface hydrophilicity and easy availability of raw materials , the effect of high ultrafiltration coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

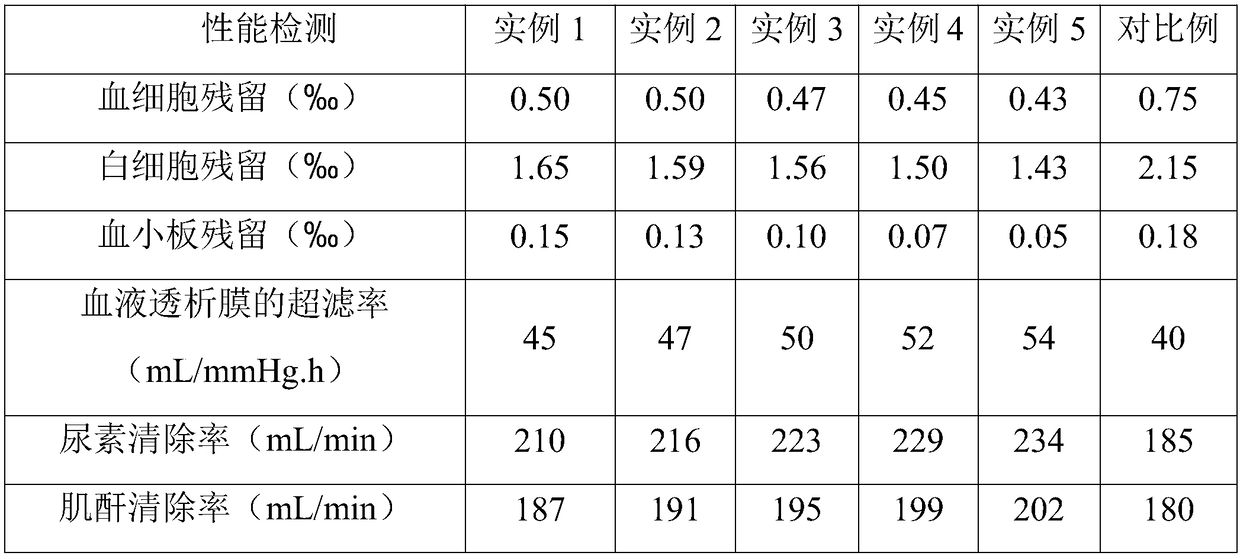

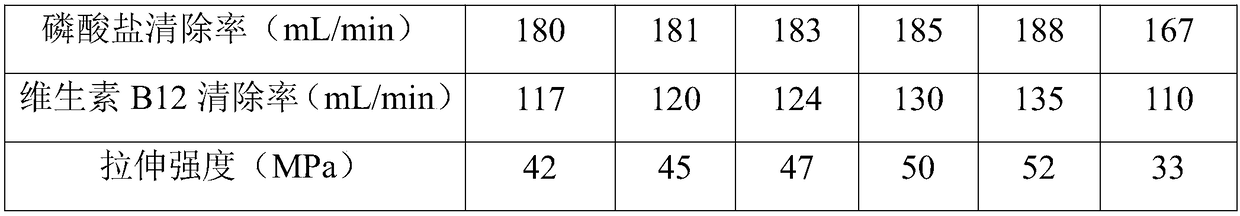

Examples

Embodiment 1

[0031] A method for preparing a dialysis membrane for a hemodialyzer, comprising the steps of:

[0032] ⅠDissolve 1kg of 3,4-dihydroxyfuran-2,5-dicarboxylate diethyl ester, 2kg of 4,6-bis(1-adamantyl)-1,3-diglycidyl ether benzene in dimethyl ethylene Add 0.3 kg of sodium carbonate to 10 kg of sulfone, stir and react for 12 hours in a nitrogen atmosphere at 75 ° C, then precipitate in water, then filter the precipitated polymer with suction, and dry it in a vacuum oven at 90 ° C until constant Heavy, obtain adamantyl furyl condensation polymer;

[0033] II Dissolving 1 kg of the adamantyl furanyl polycondensate prepared in step I in 4 kg of N,N-dimethylformamide, vacuum defoaming to obtain a spinning solution, injecting the spinning solution into a spinning solution tank, Adjust the pressure to 3 atmospheres, control the temperature to 70 degrees Celsius, and control the speed of the collection drum to 800 rpm, and then spin to obtain the membrane material;

[0034] Ⅲ Add 1 k...

Embodiment 2

[0039] A method for preparing a dialysis membrane for a hemodialyzer, comprising the steps of:

[0040] Ⅰ Dissolve 1kg of 3,4-dihydroxyfuran-2,5-dicarboxylate diethyl ester and 2kg of 4,6-bis(1-adamantyl)-1,3-diglycidyl ether benzene in N,N - Add 0.35 kg of potassium carbonate to 11 kg of dimethylformamide, stir and react for 12.5 hours in a helium atmosphere at 77 ° C, and then precipitate in water, then filter the precipitated polymer with suction, and then place it in a vacuum drying oven Dried to constant weight at 93°C to obtain an adamantylfuryl polycondensate;

[0041] Ⅱ Dissolve 1 kg of the adamantyl furyl polycondensate prepared in step I in 4.5 kg of N,N-dimethylformamide, and obtain a spinning solution after vacuum defoaming treatment, and pour the spinning solution into the spinning solution tank , adjust the pressure to 3.2 atmospheres, control the temperature to 73 degrees Celsius, and control the rotating speed of the collection drum to 820 rpm, and then spin to ...

Embodiment 3

[0047] A method for preparing a dialysis membrane for a hemodialyzer, comprising the steps of:

[0048] Ⅰ Dissolve 1kg of 3,4-dihydroxyfuran-2,5-dicarboxylate diethyl ester and 2kg of 4,6-bis(1-adamantyl)-1,3-diglycidyl ether benzene in N-methyl Add 0.4 kg of sodium hydroxide to 13 kg of pyrrolidone, stir and react for 13 hours in a neon atmosphere at 79 ° C, then precipitate in water, then filter the precipitated polymer with suction, and then place it in a vacuum drying oven at 95 ° C Dry to constant weight to obtain adamantyl furyl polycondensate;

[0049] II Dissolving 1 kg of the adamantyl furyl polycondensate prepared in step I in 5 kg of N,N-dimethylformamide, vacuum defoaming treatment to obtain a spinning solution, injecting the spinning solution into a spinning solution tank, Adjust the pressure to 3.5 atmospheres, control the temperature to 75 degrees Celsius, and control the rotating speed of the collection drum to 850 rpm, and then spin to obtain the membrane mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com