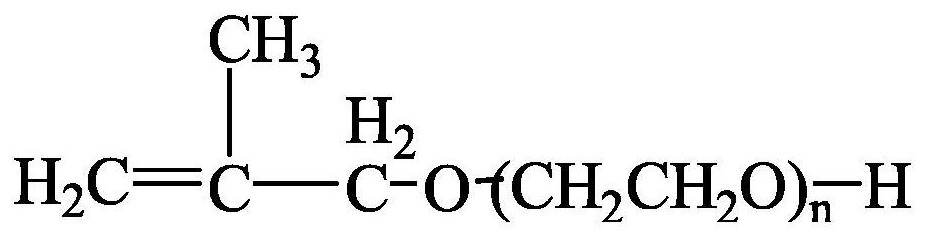

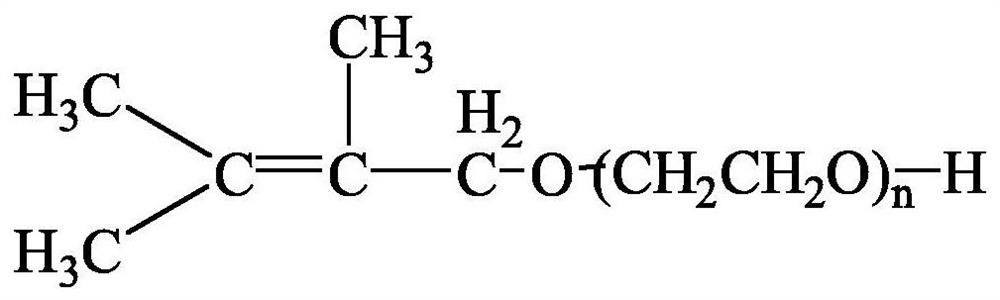

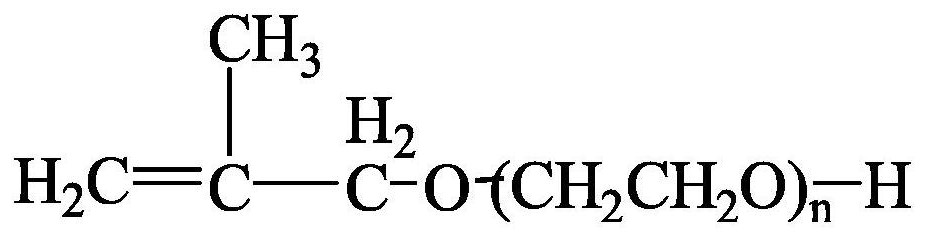

A kind of viscosity reducing type polycarboxylate water reducer and preparation method thereof

A technology of viscous polycarboxylic acid and water reducing agent, applied in the field of building admixtures, can solve the problems of large molecular weight, small molecular weight of viscosity reducing agent, low water reducing rate, etc., to improve dispersion performance, reduce surface tension, prevent colloid the effect of reunion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] (1) Get 0.8 parts by weight of vitamin C, 1.3 parts by weight of thioglycolic acid and 60 parts by weight of water to prepare the first solution;

[0043] (2) get 22 parts by weight of vinyl acetate and 40 parts by weight of water to be mixed with the second solution;

[0044] (3) get 40 parts by weight of acrylic acid and 20 parts by weight of water to be mixed with the third solution;

[0045] (4) In the reaction device, add 350 parts by weight of methallyl polyoxyethylene ether and 294 parts by weight of water, stir, mix and dissolve at 25-35°C;

[0046] (5) Add 8 parts by weight of maleic anhydride in the material of step (4), add 3.8 parts by weight of hydrogen peroxide after stirring and dissolving;

[0047] (6) Add one-third of the first solution and all the second solution dropwise within 60 minutes, and then keep warm for 1 hour at 30°C to 45°C to carry out the polymerization reaction;

[0048] (7) Add the remaining two-thirds of the first solution and the th...

Embodiment 2

[0050] (1) Get 2.8 parts by weight of sodium bisulfite, 1.2 parts by weight of mercaptoethanol and 60 parts by weight of water to be mixed with the first solution;

[0051] (2) get 20 parts by weight of vinyl acetate and 40 parts by weight of water to be mixed with the second solution;

[0052] (3) get 42 parts by weight of methacrylic acid and 20 parts by weight of water to be mixed with the third solution;

[0053] (4) In the reaction device, add 370 parts by weight of prenyl polyoxyethylene ether and 294 parts by weight of water, stir, mix and dissolve at 25-35°C;

[0054] (5) Add 9 parts by weight of maleic anhydride in the material of step (4), add 5.2 parts by weight of azobisisobutyronitrile after stirring and dissolving;

[0055](6) Add one-third of the first solution and all the second solution dropwise within 60 minutes, and then keep warm for 1 hour at 30°C to 45°C to carry out the polymerization reaction;

[0056] (7) Add the remaining two-thirds of the first sol...

Embodiment 3

[0058] (1) Get 0.9 parts by weight of oxalic acid, 1.3 parts by weight of mercaptoethanol and 60 parts by weight of water to prepare the first solution;

[0059] (2) get 23 parts by weight of vinyl acetate and 40 parts by weight of water to be mixed with the second solution;

[0060] (3) Get 20 parts by weight of acrylic acid, 18 parts by weight of itaconic acid and 20 parts by weight of water to prepare the third solution;

[0061] (4) In the reaction device, add 370 parts by weight of prenyl polyoxyethylene ether and 310 parts by weight of water, stir, mix and dissolve at 25-35°C;

[0062] (5) add 12 parts by weight of maleic anhydride in the material of step (4), add 4.8 parts by weight of hydrogen peroxide after stirring and dissolving;

[0063] (6) Add one-third of the first solution and all the second solution dropwise within 60 minutes, and then keep warm for 1 hour at 30°C to 45°C to carry out the polymerization reaction;

[0064] (7) Add the remaining two-thirds of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com