A method for preparing aluminum-iron flocculant from red mud

A flocculant, red mud technology, applied in chemical instruments and methods, flocculation/sedimentation water/sewage treatment, iron compounds, etc., can solve the problems of strong acidity of leaching residue, complex process, affecting flocculation effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

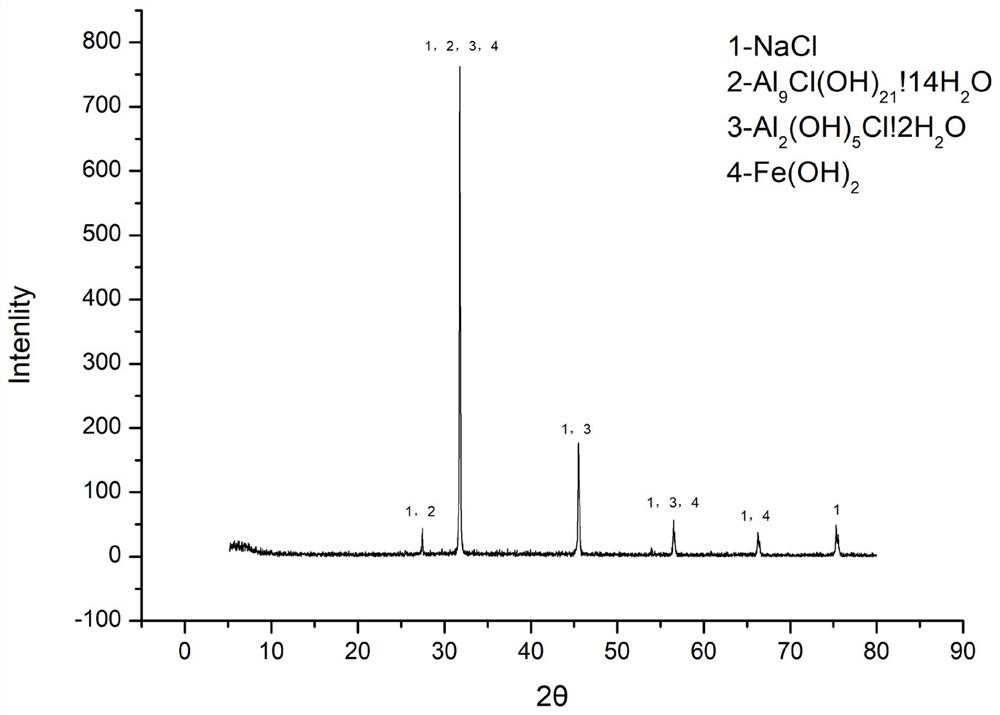

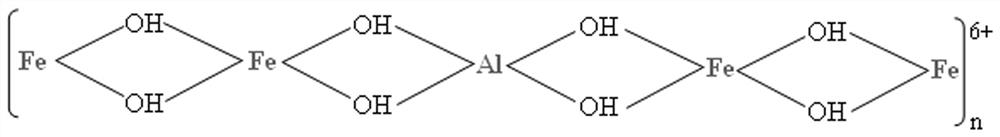

Image

Examples

Embodiment 1

[0031] Stir and dissolve the mixed leaching acid and water according to the mass ratio of 1:3-5, the dissolution condition: the temperature is 50 o C-90 o C, the stirring intensity is 450-750r / min, the stirring time is 30-90min, and the leaching solvent is obtained after complete dissolution; the mixed polymeric acid and water are stirred and dissolved according to the mass ratio of 1:2-3, and the dissolution conditions are: temperature 20 o C-50 o C, the stirring intensity is 300-600r / min, the stirring time is 90-180min, and the polymerization solvent is obtained after completely dissolving; the water washing residue and the leaching solvent are mixed in a beaker, and the solid-liquid mass ratio is 1:6-7, the reaction temperature is 80 o C-100 o C. Stir for 30-90min under the condition of stirring intensity of 250-400r / min. After the stirring is finished, the solid-liquid separation obtains leaching tailings and pickling solution; the washing solution is added dropwise to...

Embodiment 2

[0033] Stir and dissolve the mixed leaching acid and water according to the mass ratio of 1:5-7, the dissolution condition: the temperature is 50 o C-90 o C, the stirring intensity is 450-750r / min, the stirring time is 30-90min, and the leaching solvent is obtained after completely dissolving for later use; the mixed polymeric acid and water are stirred and dissolved under the condition that the mass ratio is 1:3-4, and the dissolution condition is temperature 20 o C-50 o C, the stirring intensity is 300-600r / min, the stirring time is 90-180min, and the polymerization solvent is obtained after complete dissolution. Mix the washed slag and the leaching solvent in a beaker at a solid-to-liquid mass ratio of 1:4-6 and a reaction temperature of 80 o C-100 o C. Stir for 30-90min under the condition of stirring intensity of 250-400r / min. After the stirring is finished, the solid-liquid separation obtains leaching tailings and pickling solution; the washing solution is added drop...

Embodiment 3

[0035] Stir and dissolve the mixed leaching acid and water according to the mass ratio of 1:7-9, and the dissolution condition is that the temperature is 50 o C-90 o C, the stirring intensity is 450-750r / min, the stirring time is 30-90min, and the leaching solvent is obtained after completely dissolving for later use; the mixed polymeric acid and water are stirred and dissolved under the condition that the mass ratio is 1:3-4, and the dissolution condition is temperature 20 o C-50 o C, the stirring intensity is 300-600r / min, the stirring time is 90-180min, and the polymerization solvent is obtained after completely dissolving; the water washing residue and the leaching solvent are mixed in a beaker, and the solid-liquid mass ratio is 1:3-4. temperature is 80 o C-100 o C. Stir for 30-90min under the condition of stirring intensity of 250-400r / min. After the stirring is finished, the solid-liquid separation obtains leaching tailings and pickling solution; the washing solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com