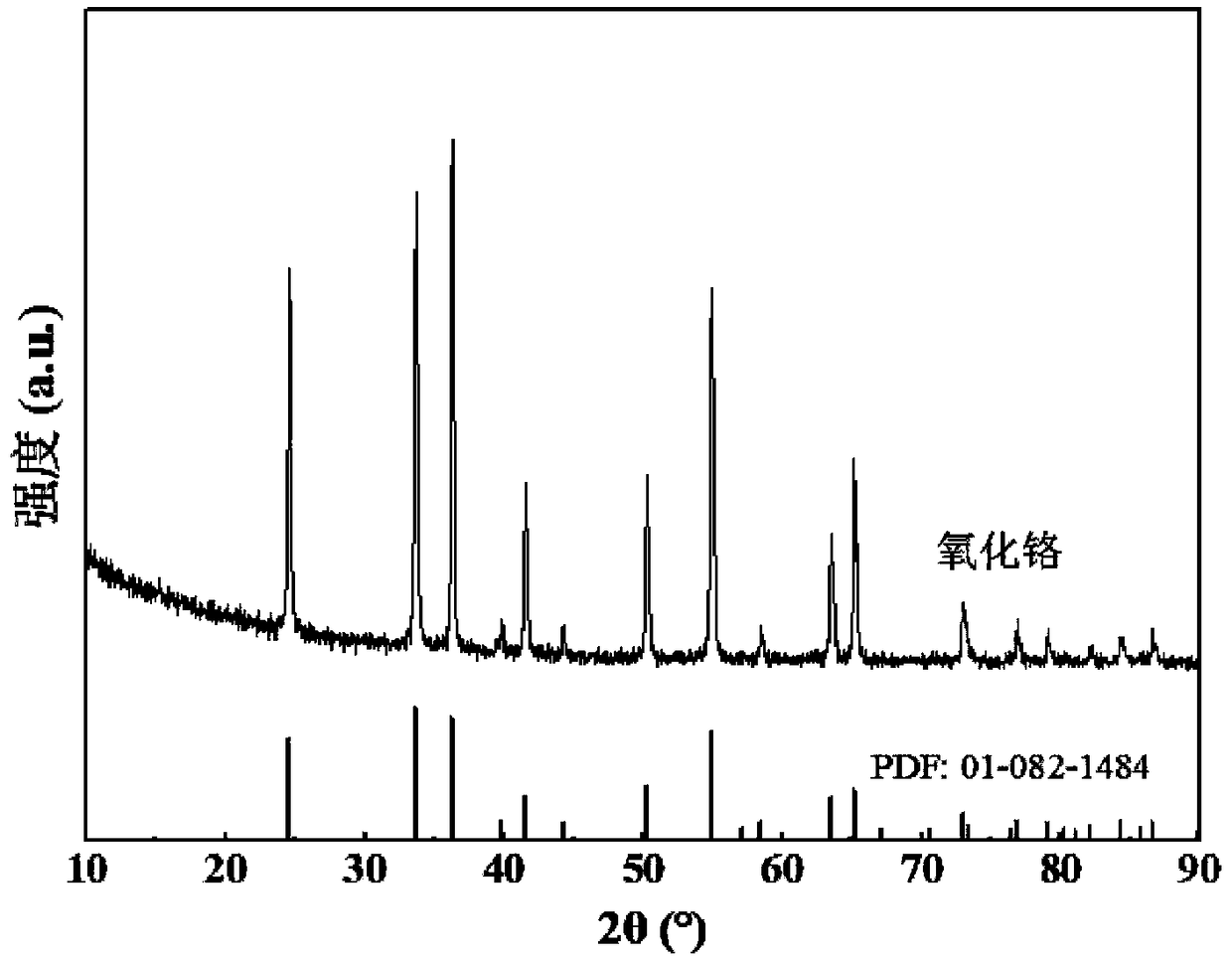

Chromic oxide and preparation method thereof

A chromium oxide, seed crystal technology, applied in the direction of chromium oxide/hydrate, can solve the problems of reaction temperature, high pressure, long process, difficult to control the reaction process, etc., to shorten the reaction time, reduce the reaction temperature, and improve the nucleation. effect of speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0061] The specific embodiment part of the present invention provides a kind of preparation method of chromium oxide, described method comprises the following steps:

[0062] (1) Adding the hexavalent chromium salt solution containing the crystal seed into the reaction device, feeding the protective gas and raising the temperature in an airtight manner, after reaching the target temperature, continuously feeding the reducing gas to react, and obtaining the mixed slurry;

[0063] (2) separating the mixed slurry obtained in step (1) from solid to liquid to obtain chromium oxyhydroxide powder;

[0064] (3) Calcining the chromium oxyhydroxide powder obtained in step (2) to obtain chromium oxide.

Embodiment 1

[0067] The present embodiment provides a kind of preparation method of chromium oxide, described method comprises the following steps:

[0068] (1) Put 200mL of sodium chromate solution with a concentration of 0.2mol / L in a vertical reactor with a volume of 500mL, add 0.1g of chromium oxyhydroxide seed crystals, feed nitrogen to discharge the air in the reactor and pipeline, and seal Afterwards, the temperature was raised by program, the stirring rate was 200r / min, and after reaching the target reaction temperature of 240°C, hydrogen gas was introduced to react, and the partial pressure of hydrogen gas was maintained at 2MPa. After 1 hour of reaction, the temperature was rapidly cooled by water cooling, and the cooling rate was 10°C / min, and a mixed slurry was obtained. material;

[0069] (2) suction-filtering the mixed slurry obtained in step (1) to obtain a solid and a filtrate, the gained solid is washed and dried to obtain a chromium oxyhydroxide powder;

[0070] (3) Calc...

Embodiment 2

[0074] The present embodiment provides a kind of preparation method of chromium oxide, described method comprises the following steps:

[0075] (1) The potassium chromate solution that 200mL concentration is 0.6mol / L is placed in the horizontal reaction kettle that volume is 500mL, adds 0.05g chromium oxyhydroxide seed crystal, feeds helium gas and discharges the air in the reaction kettle and pipeline, After sealing, the temperature was programmed and the stirring rate was 100r / min. After reaching the target reaction temperature of 200°C, hydrogen gas was introduced to react, and the partial pressure of hydrogen gas was maintained at 8MPa. After 3 hours of reaction, the temperature was rapidly cooled by water cooling at a cooling rate of 5°C / min, and a mixture was obtained. slurry;

[0076](2) suction-filtering the mixed slurry obtained in step (1) to obtain a solid and a filtrate, the gained solid is washed and dried to obtain a chromium oxyhydroxide powder;

[0077] (3) Ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com