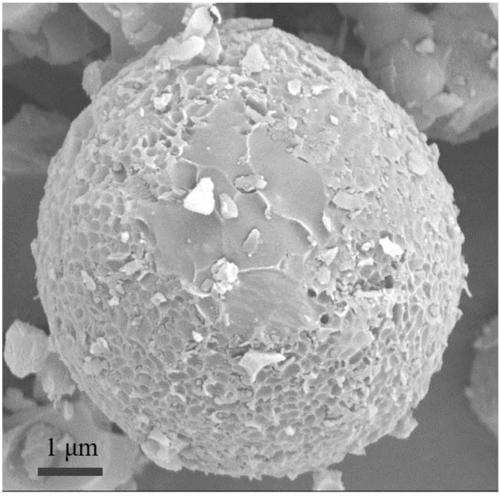

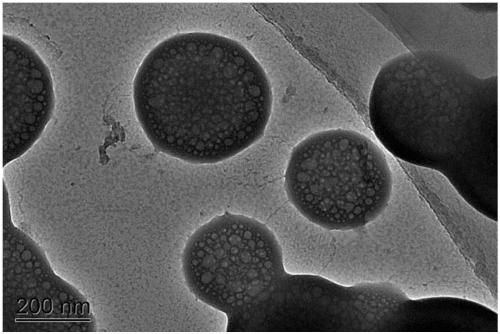

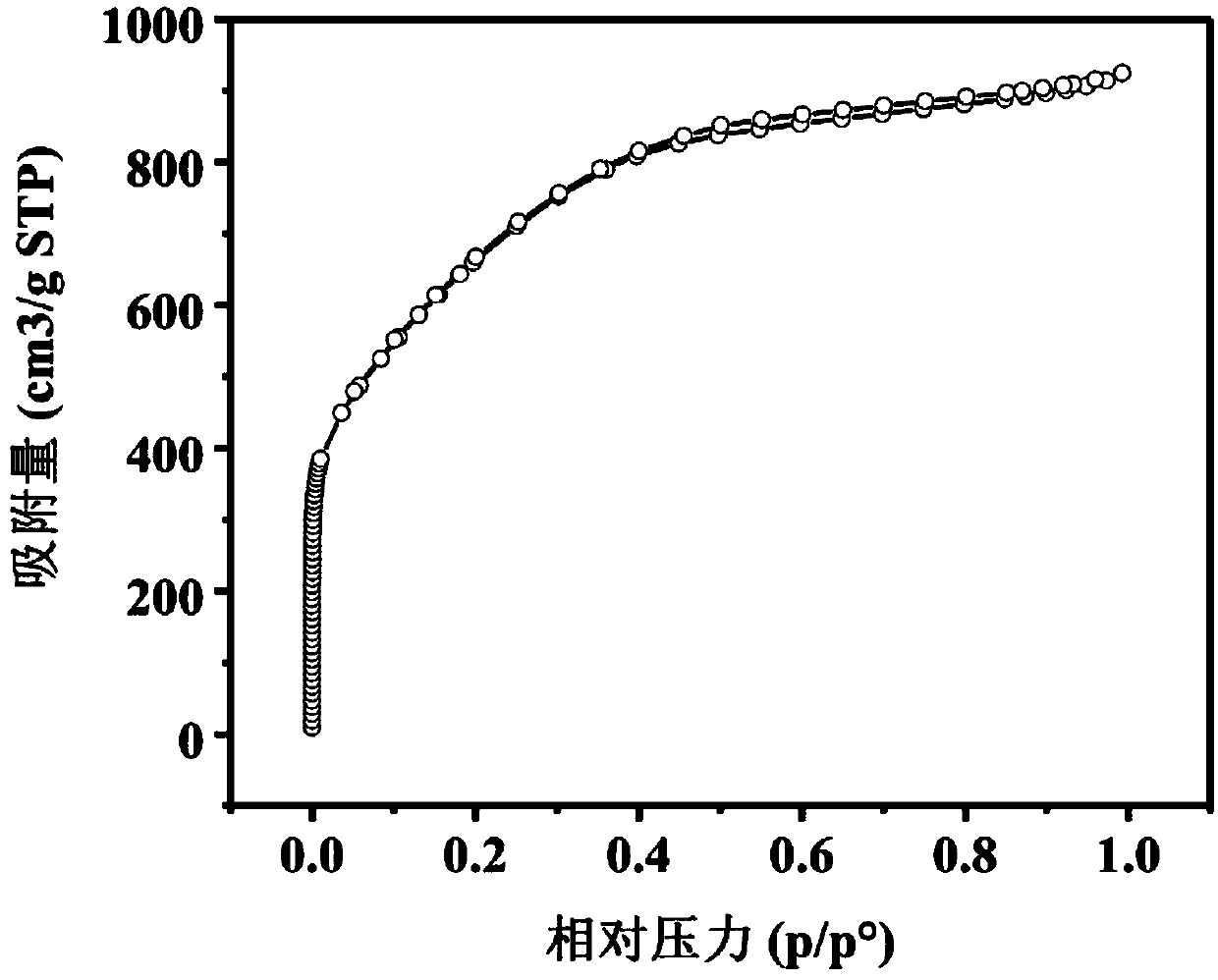

Chitosan-based porous carbon sphere and preparation method thereof

A chitosan and porous carbon technology, applied in chemical instruments and methods, carbon compounds, other chemical processes, etc., can solve the problems that limit the efficient utilization of chitosan-based carbon materials, the low efficiency of hydrothermal carbonization into spheres, and the shape of carbon materials. irregular appearance and other problems, to achieve the effects of low cost, strong physical and chemical stability, and improved porosity and specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A preparation method of chitosan-based porous carbon spheres, the specific steps are as follows:

[0037] (1) Add 0.5 g of chitosan with a molecular weight of 50,000 Da to 500 mL of dilute hydrochloric acid solution with a concentration of 0.1 mol / L to dissolve it at a stirring rate of 600 rpm, and obtain the mass fraction (g / mL ) is 0.1% chitosan solution;

[0038] (2) Transfer the chitosan solution prepared in step (1) to a hydrothermal reaction kettle, heat it to 180 °C, and conduct hydrothermal carbonization at a constant temperature for 8 hours. Press and dry at 30°C to obtain black powder, which is chitosan-based carbon spheres;

[0039] (3) According to the mass ratio of chitosan-based carbon spheres and KOH particles of 1:0.1, weigh 0.25 g of chitosan-based carbon spheres and 0.025 g of KOH particles obtained in step (2) respectively, place them in an agate mortar, grind and mix Finally, in a nitrogen atmosphere, the temperature was raised to 600 °C in a tube ...

Embodiment 2

[0042] A preparation method of chitosan-based porous carbon spheres, the specific steps are as follows:

[0043] (1) Under the condition of stirring rate of 700 rpm, 5 g of chitosan with a molecular weight of 200,000 Da was added to 500 mL of dilute hydrochloric acid solution system with a concentration of 1 mol / L to dissolve it, and the mass fraction (g / mL) is 1% chitosan solution;

[0044] (2) Transfer the chitosan solution prepared in step (1) to a hydrothermal reaction kettle, heat it to 200 °C, and conduct hydrothermal carbonization at a constant temperature for 12 h. After the reaction, cool to room temperature and dialyze with a 3000 D dialysis bag. Vacuum drying at 50 °C to obtain black powder, which is chitosan-based carbon spheres;

[0045](3) According to the mass ratio of chitosan-based carbon spheres and KOH particles of 1:0.5, weigh 0.5 g of chitosan-based carbon spheres and 0.25 g of KOH particles obtained in step (2) respectively, place them in an agate morta...

Embodiment 3

[0048] A preparation method of chitosan-based porous carbon spheres, the specific steps are as follows:

[0049] (1) Add 20 g of chitosan with a molecular weight of 200,000 Da to 500 mL of dilute hydrochloric acid solution with a concentration of 2 mol / L at a stirring rate of 1000 rpm to obtain the mass fraction (g / mL ) is 4% chitosan solution;

[0050] (2) Transfer the chitosan solution prepared in step (1) to a hydrothermal reactor, heat it to 250 °C, and conduct constant temperature hydrothermal carbonization for 24 h. After the reaction, cool to room temperature and dialyze with a 3000 D dialysis bag. Freeze drying to obtain a black powder, which is chitosan-based carbon spheres;

[0051] (3) According to the mass ratio of chitosan-based carbon spheres and KOH particles of 1:3, weigh 0.5 g of chitosan-based carbon spheres and 1.5 g of KOH particles obtained in step (2), place them in an agate mortar, and grind them thoroughly After mixing, in a nitrogen atmosphere, the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com