Water-based UV (ultraviolet) ink-jet ink, preparation method thereof and curing method of ink

An inkjet ink, water-based technology, used in inks, household appliances, applications, etc., can solve the problems of easy migration, increased VOCs emissions, and rapid alcohol volatilization, to reduce VOCs volatilization, avoid small molecule migration, and improve use efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

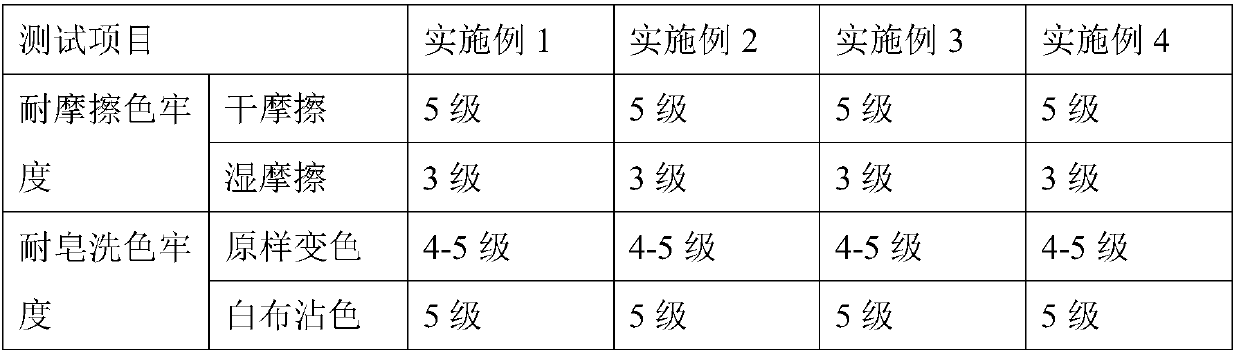

Embodiment 1

[0028] A water-based UV black inkjet ink, by weight percentage, it is made of the following components: epoxy modified polyurethane acrylate emulsion: 15%, organic fluorine modified polyurethane acrylate emulsion: 3%, photoinitiator GC -410: 2%, photoinitiator PolymericTPO-L: 1%, acryloyl morpholine: 8%, polyethylene glycol (400) acrylate: 7%, propylene glycol: 20%, wetting agent PE-100: 0.5 %, defoamer FS-620: 0.05%, triethanolamine: 1%, fungicide HY-606D-2: 0.1%, water-based nano black paste: 30%, deionized water: the rest; the photoinitiator GC- 410. Photoinitiator PolymericTPO-L, acryloyl morpholine, polyethylene glycol (400) acrylate, wetting agent PE-100, defoamer FS-620 are stirred and mixed according to the weight percentage, and then add ring Oxygen-modified urethane acrylate emulsion, organic fluorine-modified urethane acrylate emulsion, triethanolamine, bactericide HY-606D-2 and deionized water, stirred and mixed evenly, and then filtered to obtain the water-based U...

Embodiment 2

[0031] A water-based UV red inkjet ink, by weight percentage, it is made of the following components: epoxy soybean oil modified polyurethane acrylate emulsion: 8%, silicone modified acrylate emulsion: 3%, photoinitiator GC-409: 3%, photoinitiator Omnipol TX: 1%, acryloyl morpholine: 10%, polyethylene glycol (600) acrylate: 5%, glycerol: 15%, water-based nano red paste: 25% %, wetting agent surfynol 465: 0.1%, wetting agent SD-200: 0.2%, defoamer FS-640: 0.1%, ammonia water: 1%, fungicide HY-606D-2: 0.1%, deionized water : remaining amount; The preparation process of described aqueous UV red ink-jet ink is similar to embodiment 1.

[0032] Wherein, by weight percentage, the water-based nano red paste is made of the following components: pigment red V19: 20%, wetting agent WA-6802: 2.5%, dispersant Tego 655: 20%, defoamer BYK- A506: 2%, triethylamine: 1%, fungicide MIT: 1%, deionized water: the balance; the preparation process of the water-based nano red paste is similar to th...

Embodiment 3

[0034] A water-based UV yellow inkjet ink, by weight percentage, it is made of the following components: fluorine silicon modified urethane acrylate emulsion: 10%, castor oil modified urethane acrylate emulsion: 3%, photoinitiator GC -412: 2%, photoinitiator Omnipol 3TX: 2%, acryloyl morpholine: 12%, ethoxylated trimethylolpropane triacrylate: 3%, polyethylene glycol: 20%, water-based nano yellow paste: 30%, wetting agent SD-200: 1%, defoamer FS-6502: 0.1%, triethylamine: 1%, fungicide HY-606D-2: 0.1%, deionized water: the rest; The preparation process of water-based UV yellow inkjet ink is similar to Example 1.

[0035] Wherein, by weight percentage, the water-based nano yellow paste is made of the following components: pigment yellow 155: 25%, wetting agent surfynol465: 1%, dispersant EFKA4185: 15%, defoamer Tego822: 1%, Triethylamine: 2%, bactericide F-046: 1.5%, deionized water: the balance; the preparation process of the water-based nano yellow paste is similar to that o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com