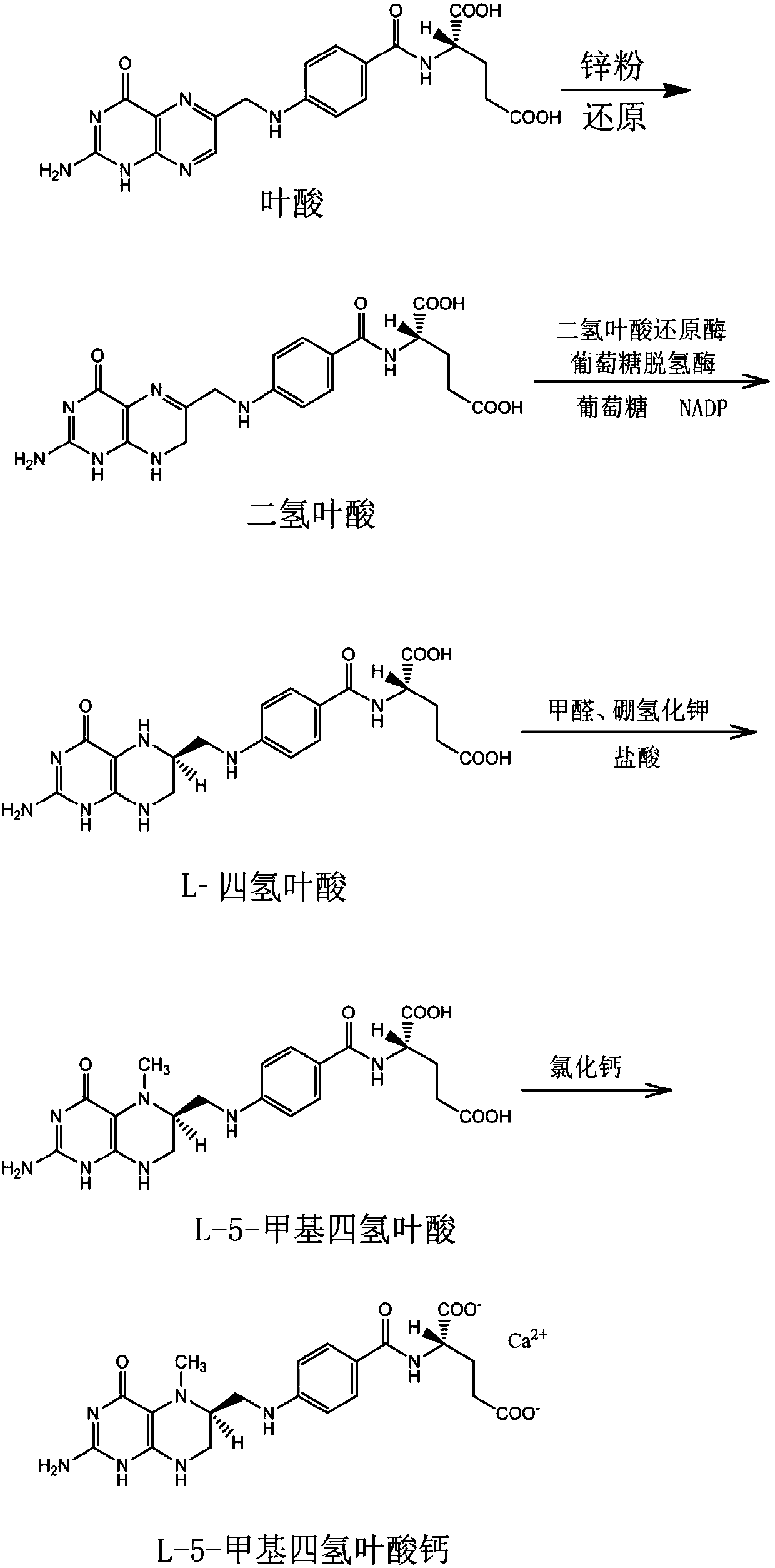

Method for preparing L-5-calcium methyl tetrahydrofolate through enzymic method

A technology for the preparation of calcium methyltetrahydrofolate and enzymatic method, which is applied in organic chemistry, fermentation, etc., can solve the problems of inability to obtain L-tetrahydrofolate, difficulty in industrialization, and large pollution, and achieve good industrialization prospects and environmental protection. Friendly, high-yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1: Preparation of dihydrofolate reductase wet bacteria.

[0029] Get Escherichia coli genetically engineered bacteria with high expression of dihydrofolate reductase, inoculate them on LB plate for pre-culture (LB medium: 5g yeast extract per liter, 10g peptone, 10g sodium chloride, 20g agar powder), and then inoculate to Continue culturing in TB shake flasks (TB medium: 24g yeast extract per liter, 12g peptone, 2g potassium dihydrogen phosphate, 16g dipotassium hydrogen phosphate trihydrate, 5g glycerin). The supernatant and bacterial precipitates were collected into ziplock bags and frozen in a -20°C refrigerator for later use.

Embodiment 2

[0030] Example 2: Preparation of glucose dehydrogenase wet cells.

[0031] Take Escherichia coli genetically engineered bacteria with high glucose dehydrogenase expression, inoculate them on LB plate for pre-cultivation (LB medium: 5g yeast extract per liter, 10g peptone, 10g sodium chloride, 20g agar powder), and then inoculate into TB plate Continue culturing in shake flasks (TB medium: 24g yeast extract per liter, 12g peptone, 2g potassium dihydrogen phosphate, 16g dipotassium hydrogen phosphate trihydrate, 5g glycerin), collect the bacteria by centrifugation after the culture is completed, and discard the supernatant solution, and bacterial precipitates were collected in ziplock bags, and frozen in a -20°C refrigerator for later use.

Embodiment 3

[0033] (1) Add 100g of folic acid and 1000ml of water into a 2000ml reaction bottle, and add the pre-prepared NaOH solution (60gNaOH+165ml of water) dropwise under stirring. After the dropwise addition, add 50g of zinc powder, react at 10°C for 1 hour, add phosphoric acid to adjust the pH of the reaction solution to 7.0, and filter to obtain a dihydrofolic acid solution;

[0034] (2) Add 10g glucose dehydrogenase fermented wet cells and 20g dihydrofolate reductase wet cells to the filtrate, 45g glucose, 0.2g NADP, 10g disodium EDTA, react at 10°C for 1 hour, filter after the reaction, adjust with hydrochloric acid pH to 3.3, filtered to obtain L-tetrahydrofolic acid wet powder.

[0035] (3) Add the above-mentioned L-tetrahydrofolic acid wet powder into a 5000ml reaction bottle, add 600ml of water, adjust the pH to 7.5 with NaOH, and add 6.3ml of formaldehyde (1.0eq, calculated as folic acid) dropwise. Lower the temperature to 10°C, add sodium borohydride solution (25.7g (3eq,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com