Radical-trapping lithium battery anode

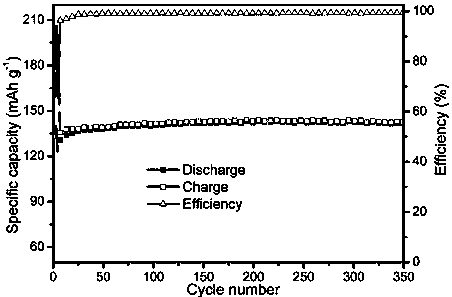

A free radical and lithium battery technology, applied in battery electrodes, secondary batteries, non-aqueous electrolyte batteries, etc., can solve problems such as adverse effects on battery cycle performance, degradation of battery cycle performance, and destruction of the crystal structure of active materials. Integrity, reducing dissolution, and improving cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 0.8 g LiNi 0.5 mn 1.5 o 4 The positive electrode active material and 0.1 gram of acetylene black conductive agent are ground evenly in a mortar, the preparation concentration is the alkaline sodium lignosulfonate binder aqueous solution containing phenol group in the side chain of 20%, the obtained binder aqueous solution Slowly add to the uniformly mixed powder of the positive electrode active material and the conductive agent and continue to grind, the mass ratio of the binder to the positive electrode active material is 1:8, the obtained uniform slurry is coated on a clean aluminum foil, and the electrode The sheet was left at room temperature for 2 hours, then further dried in an oven at 60°C to remove the solvent, and finally the electrode sheet was transferred to a vacuum oven at 90°C to dry under vacuum for 24 hours.

[0031] The dried pole piece is prepared into a pole piece with a diameter of 14 mm, and a button battery is assembled, the lithium piece is the ...

Embodiment 2

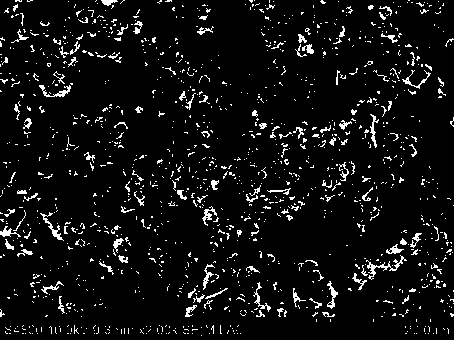

[0033] 0.8 g LiNi 0.5 mn 1.5 o 4 The positive electrode active material and 0.1 gram of acetylene black conductive agent were ground evenly in a mortar, and a polyacrylic acid binder dimethylformamide solution containing phenol groups in the side chain with a concentration of 6% was prepared. The methyl formamide solution is slowly added to the uniformly mixed powder of the positive electrode active material and the conductive agent and continuously ground, the mass ratio of the binder to the positive electrode active material is 1:8, and the obtained uniform slurry is carried out on a clean aluminum foil. For coating, place the electrode piece at room temperature for 24 hours, then further remove the solvent in an oven at 80 °C, and finally transfer the electrode piece to a vacuum oven at 120 °C to dry under vacuum for 48 hours.

[0034] Assemble the processed pole piece into a button battery, the lithium piece is the negative electrode, and the electrolyte is 1 M LiPF 6et...

Embodiment 3

[0036] 0.8 g LiNi 0.5 mn 1.5 o 4 The positive electrode active material and 0.1 gram of acetylene black conductive agent are ground evenly in a mortar, and the preparation concentration is 6% polyacrylic acid binder dimethylformamide solution containing p-trifluoromethylphenol group in the side chain, and the obtained The binder dimethylformamide solution is slowly added to the uniformly mixed powder of the positive electrode active material and the conductive agent and continuously ground, the mass ratio of the binder to the positive electrode active material is 1:8, and the obtained uniform slurry is Coating was carried out on a clean aluminum foil, and the pole piece was placed at room temperature for 24 hours, and then the solvent was further removed in an oven at 80 °C, and finally the pole piece was transferred to a vacuum drying oven at 120 °C for 48 hours under vacuum conditions.

[0037] Assemble the processed pole piece into a button battery, the lithium piece is t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific volume | aaaaa | aaaaa |

| Specific volume | aaaaa | aaaaa |

| Specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com