Method for preparing multilayer graphene by low-temperature molten salt

A multi-layer graphene, low temperature molten salt technology, applied in graphene, nano carbon and other directions, can solve the problems of explosion hazard, low controllability, explosion hazard, etc., to maintain crystal integrity, not easy to pollute waste liquid, The effect of reducing the amount of acid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

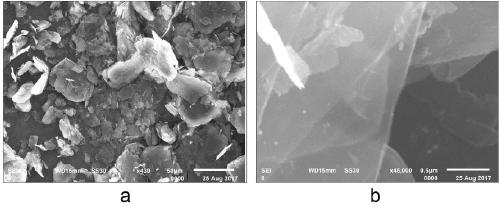

[0035] According to the method for preparing multilayer graphene in a kind of low temperature molten salt, described multilayer graphene is made according to the following steps:

[0036] S1. Place the natural graphite in a 1mol / L nitric acid solution at a temperature of 50°C and stir for 2 hours. The nitric acid solution reacts with the soluble metal oxides in the natural graphite to form nitrate, which can remove impurities in the natural graphite and effectively Improve the obtained multilayer graphene purity, then filter and dry the graphite after cleaning, the drying temperature is 120°C, take by weighing 1.01g dried graphite, 6.10g lithium carbonate, 6.60g ammonium nitrate and It is mixed uniformly to obtain mixed raw materials;

[0037] S2. Put the mixed raw materials into an alumina crucible and put them into a muffle furnace at 190°C for a low-temperature reaction for 3 hours. At this time, ammonium nitrate and lithium carbonate are in a molten state, and the nitrate ...

Embodiment 2

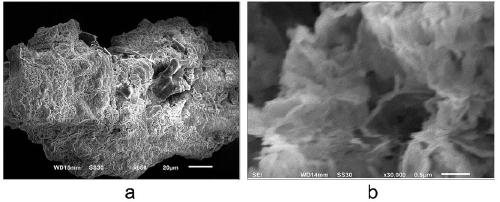

[0042] According to the method for preparing multilayer graphene in a kind of low temperature molten salt, described multilayer graphene is made according to the following steps:

[0043]S1. Place the natural graphite in a 1mol / L nitric acid solution at a temperature of 50°C and stir for 2 hours. The nitric acid solution reacts with the soluble metal oxides in the natural graphite to form nitrate, which can remove impurities in the natural graphite and effectively Improve the obtained multilayer graphene purity, then filter and dry the graphite after cleaning, the drying temperature is 120 ℃, take by weighing the graphite after 1.06g drying, 6.10g lithium carbonate, 13.30g ammonium nitrate and It is mixed uniformly to obtain mixed raw materials;

[0044] S2. Put the mixed raw materials into an alumina crucible and put them into a muffle furnace at 210°C for a low-temperature reaction for 2 hours. At this time, ammonium nitrate and lithium carbonate are in a molten state, and t...

Embodiment 3

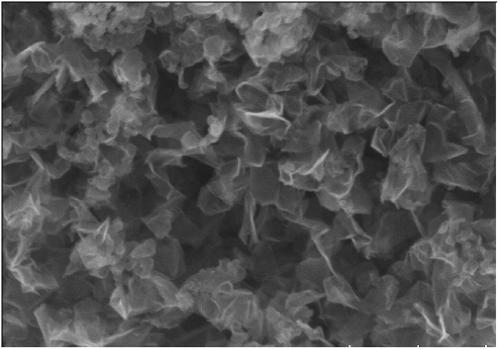

[0049] According to the method for preparing multilayer graphene in a kind of low temperature molten salt, described multilayer graphene is made according to the following steps:

[0050] S1. Place the natural graphite in a 1mol / L nitric acid solution at a temperature of 50°C and stir for 2 hours. The nitric acid solution reacts with the soluble metal oxides in the natural graphite to form nitrate, which can remove impurities in the natural graphite and effectively Improve the obtained multilayer graphene purity, then filter and dry the graphite after cleaning, the drying temperature is 120°C, take by weighing 1.06g dried graphite, 1.53g lithium carbonate, 24.00g ammonium nitrate and It is mixed uniformly to obtain mixed raw materials;

[0051] S2. Put the mixed raw materials into an alumina crucible and put them into a muffle furnace at 240°C for 1.5 hours of low-temperature reaction. At this time, ammonium nitrate and lithium carbonate are in a molten state, and the nitrate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com