Composite plant extracting solution moisture-preserving composition and preparation method thereof

A technology of plant extract and composition, applied in the field of skin care products, can solve the problem of not producing moisturizing cosmetic compositions and the like, and achieve the effect of good moisturizing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] Preparation of compound plant extract:

[0018] (1) Weigh 6 kg of yacon, 3 kg of Agaricus bisporus, 3 kg of Tremella, 2 kg of Fucus algae, and 2 kg of Haematoderma palmitate, washed and chopped.

[0019] (2) Add the above-mentioned raw materials into a stainless steel extraction tank, add 20 grams of amylase, 10 grams of cellulase, 5 grams of pectinase, 10 grams of glucanase, and 84 kilograms of purified water.

[0020] (3) Under the condition of 30-40°C, the above-mentioned plant raw material is subjected to enzymatic digestion for 2 hours.

[0021] (4) Filter the mixture after enzymolysis and digestion with a 200-mesh filter cloth, and then heat the filtrate to 85° C. for 5 min. After the killing enzyme is inactivated, the liquid is filtered with a 200-mesh filter cloth.

[0022] (5) After the filtrate is cooled to 40° C., 0.3 kg of preservative bis(hydroxymethyl)imidazolidinyl urea is added, and the mixture is stirred evenly to obtain the composite plant extract. ...

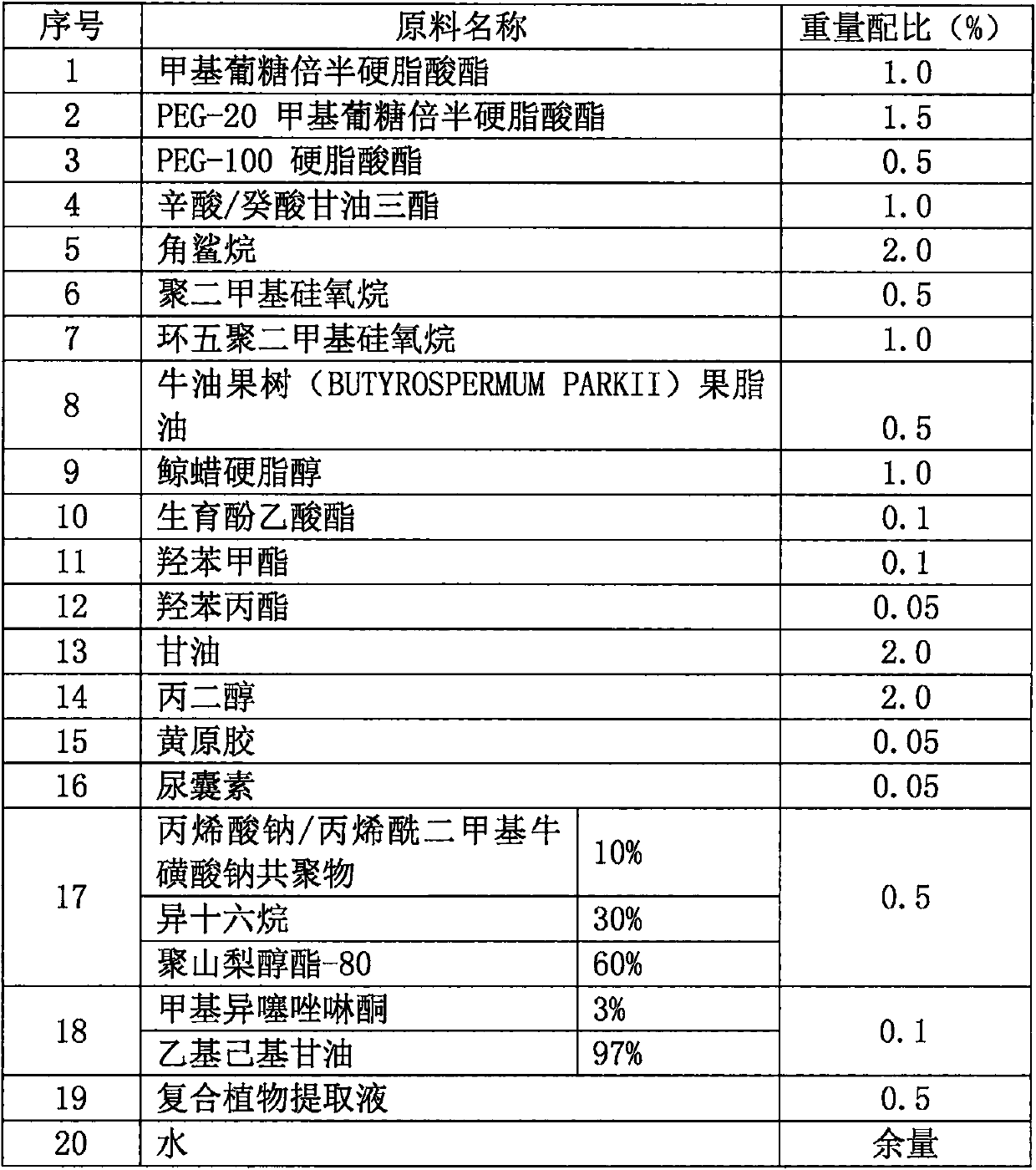

Embodiment 1

[0034] Sample 1 preparation process:

[0035] 1. Add the A phase raw materials (water, glycerol, propylene glycol, xanthan gum, allantoin) into the emulsification pot according to the amount in turn, stir at a speed of 28 rev / min, and heat up to 82°C.

[0036] 2. The B phase raw materials (methyl glucose sesquistearate, PEG-20 methyl glucose sesquistearate, PEG-100 stearate, caprylic / capric triglyceride, squalane Alkane, Dimethicone, Cyclopentasiloxane, Shea Butter (BUTYROSPERMUM PARKII) Butter Oil, Cetearyl Alcohol, Tocopheryl Acetate, Methylparaben, Propylparaben ) were added to the oil pan according to the amount in turn, stirred at a speed of 28 rev / min, and heated to 82°C.

[0037] 3. Pump the material in the oil pot into the emulsification pot and stir evenly. Then add the C-phase raw materials (sodium acrylate / sodium acryloyldimethyltaurate copolymer, isohexadecane, polysorbate-80) into the emulsifying pot.

[0038] 4. Vacuum, vacuum degree -0.06mpa, open homogenizat...

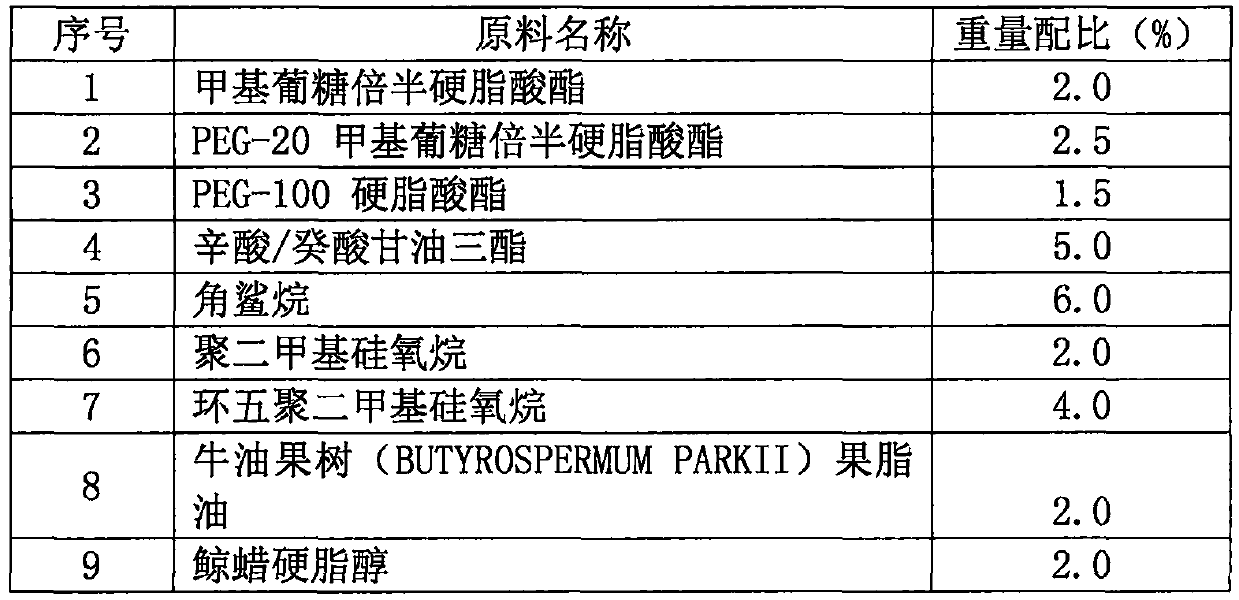

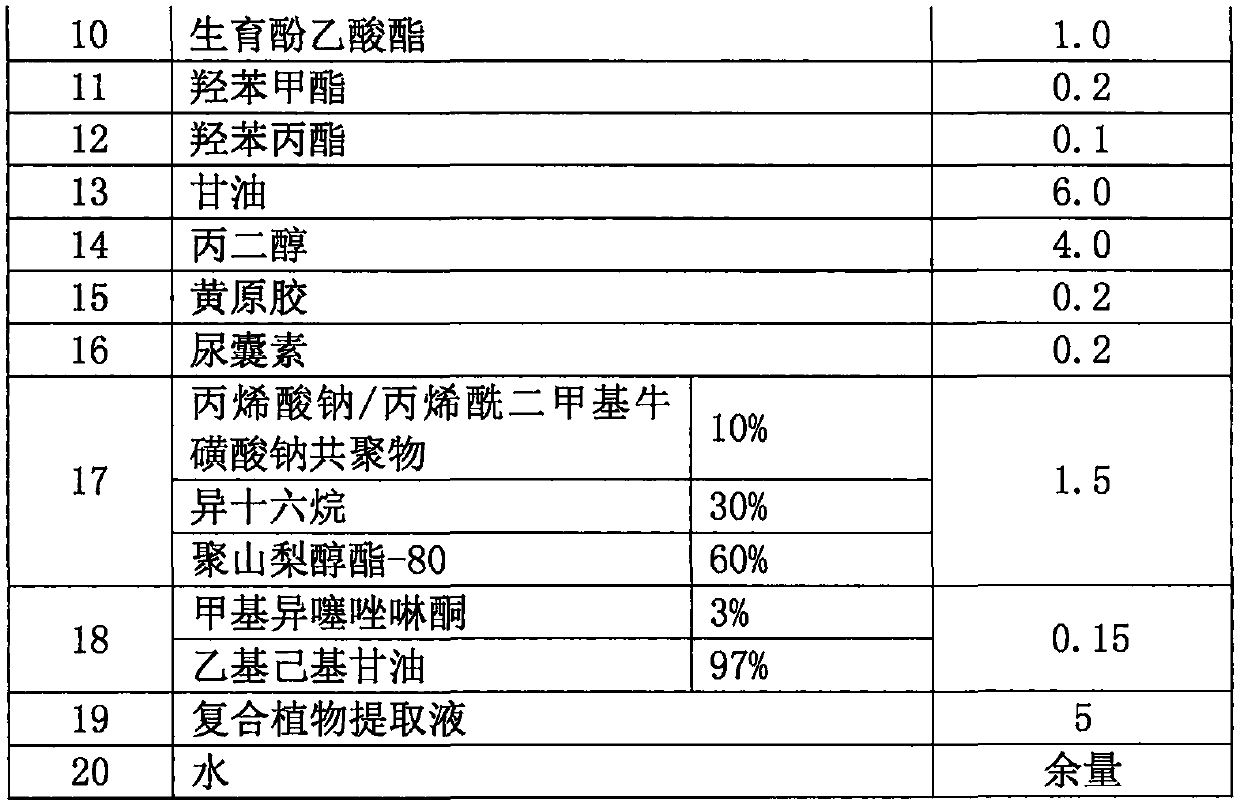

Embodiment 2

[0044] Sample 2 preparation process:

[0045] 1. Add the A phase raw materials (water, glycerol, propylene glycol, xanthan gum, allantoin) into the emulsification pot according to the amount in turn, stir at a speed of 28 rev / min, and heat up to 82°C.

[0046]2. The B phase raw materials (methyl glucose sesquistearate, PEG-20 methyl glucose sesquistearate, PEG-100 stearate, caprylic / capric triglyceride, squalane Alkane, Dimethicone, Cyclopentasiloxane, Shea Butter (BUTYROSPERMUM PARKII) Butter Oil, Cetearyl Alcohol, Tocopheryl Acetate, Methylparaben, Propylparaben ) were added to the oil pan according to the amount in turn, stirred at a speed of 28 rev / min, and heated to 82°C.

[0047] 3. Pump the material in the oil pot into the emulsification pot and stir evenly. Then add the C-phase raw materials (sodium acrylate / sodium acryloyldimethyltaurate copolymer, isohexadecane, polysorbate-80) into the emulsifying pot.

[0048] 4. Vacuum, vacuum degree -0.06mpa, open homogenizati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com