Molybdenum disulfide/ferroferric oxide magnetic nanocomposite material and preparation method and application thereof

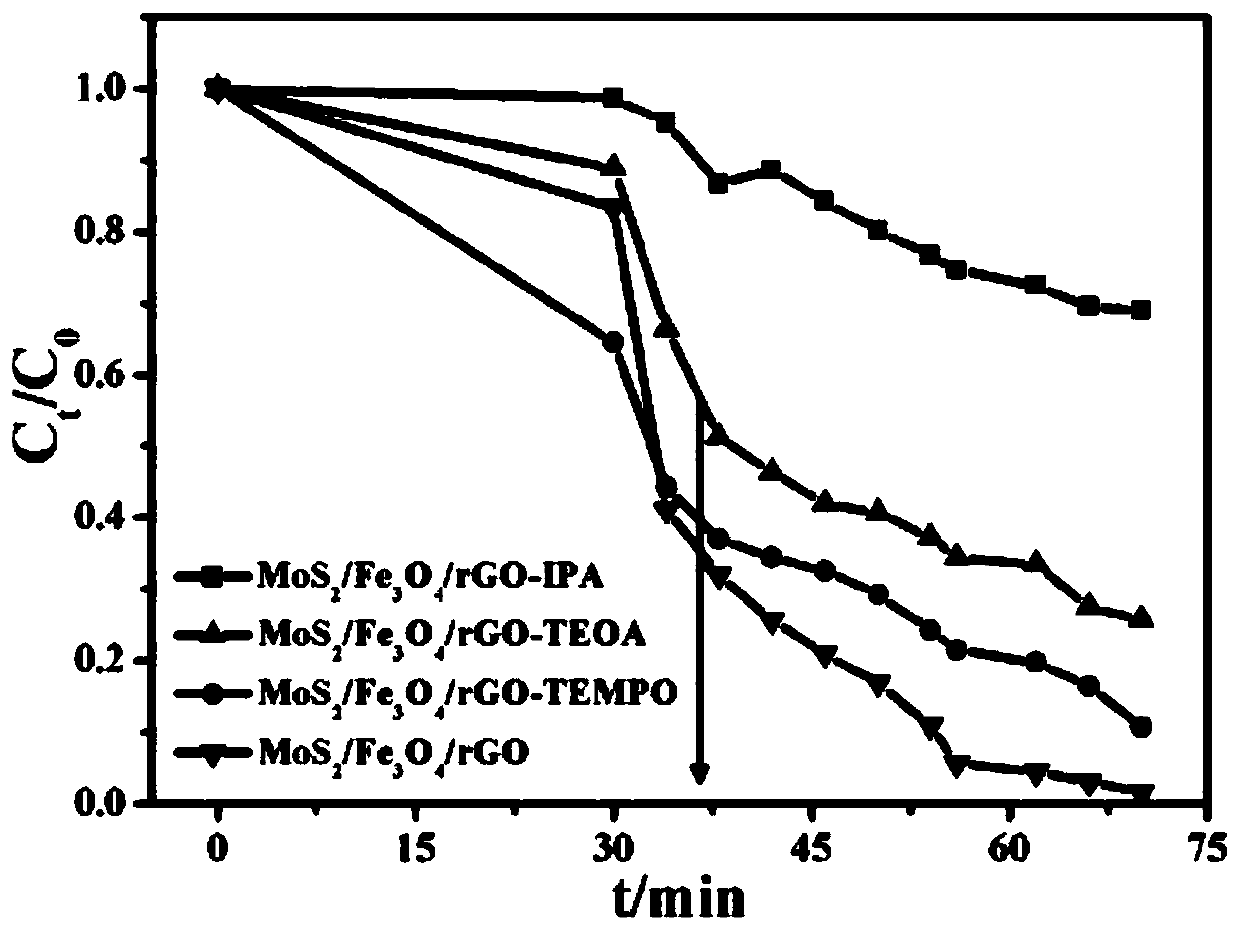

A technology of ferric oxide and molybdenum disulfide, applied in catalyst activation/preparation, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as poor electrical conductivity, low degradation rate of tetracycline, complex degradation process, etc. Achieve enhanced photocatalytic activity, excellent photocatalytic effect, and good cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

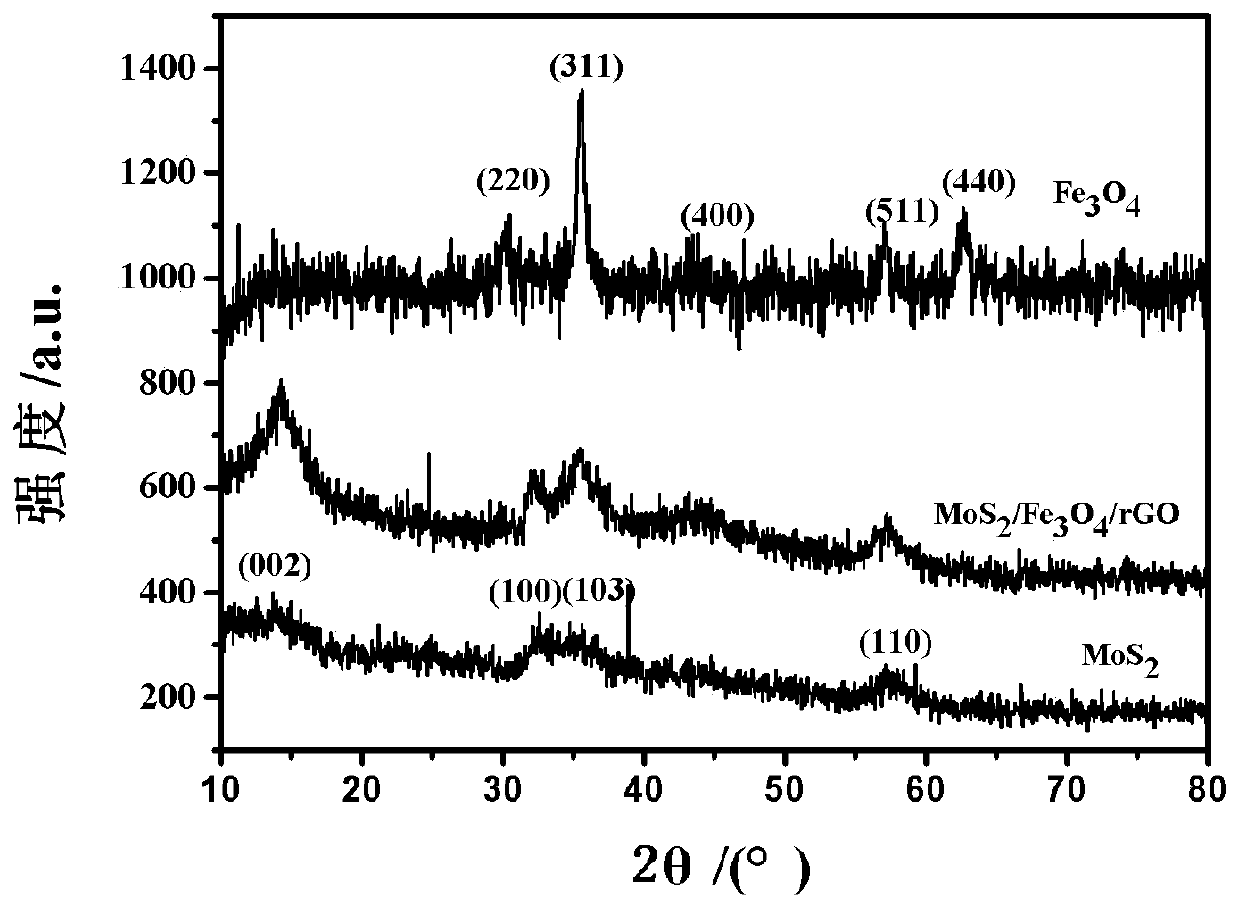

[0032] The present invention provides the preparation method of the molybdenum disulfide / ferroferric oxide magnetic nanocomposite material according to the above technical solution, comprising the following steps:

[0033] The L-cysteine solution, the sodium molybdate solution and the ferric tetroxide nano-particle dispersion are mixed to carry out a hydrothermal synthesis reaction to obtain the molybdenum disulfide / ferric tetroxide magnetic nanocomposite material.

[0034] In the present invention, the concentration of the L-cysteine solution is preferably 0.01-0.03 mol / L, more preferably 0.015-0.025 mol / L, and most preferably 0.02 mol / L. In the present invention, the concentration of the sodium molybdate solution is preferably 0.01-0.03 mol / L, more preferably 0.01-0.025 mol / L, and most preferably 0.01-0.02 mol / L. In the present invention, the concentration of the ferric oxide nanoparticle dispersion is preferably 8-12 mg / L, more preferably 9-11 mg / L, and most preferably ...

Embodiment 1

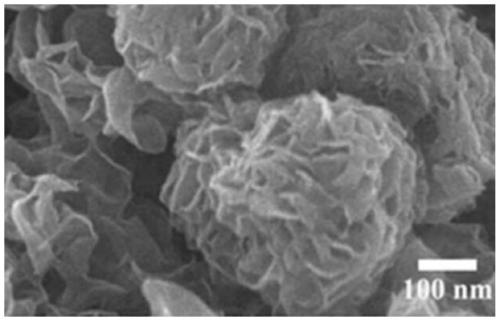

[0052] Under the condition of stirring speed of 500r / min, 10mL of sodium molybdate solution with concentration of 0.01mol / L was added dropwise to 10mL of L-cysteine solution with concentration of 0.01mol / L at a constant speed of 15 drops / min , continue to stir for 30min to obtain a mixed solution;

[0053] 10mg Fe with a particle size of 200nm 3 O 4 The particles were mixed with 1L of ultrapure water, and ultrasonically dispersed for 30min at a temperature of 25°C to obtain a dispersion of ferric oxide nanoparticles with a concentration of 10mg / L;

[0054] Add 2 mL of the ferric oxide nanoparticle dispersion and the mixed solution into the reaction kettle, stir for 80 min, and then perform a hydrothermal synthesis reaction at 180 ° C for 24 h, and then centrifuge the obtained system at 8000 r / min. 10min, the obtained solid material was washed 4 times alternately with pure water and absolute ethanol, then dissolved in absolute ethanol and air-dried to obtain Fe 3 O 4 MoS ...

Embodiment 2

[0058] The preparation was carried out according to the preparation method of Example 1, and the difference from Example 1 was that the amount of Fe3O4 nanoparticle dispersion liquid added was 4 mL to obtain Fe 3 O 4 MoS with a content of 25wt% 2 / Fe 3 O 4 Magnetic nanocomposites, labeled MoS 2 / Fe 3 O 4 (25wt%), its specific surface area is 16.8m 2 / g, the particle size is 185 nm, the yield is 90.6%, and the purity is 94.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com