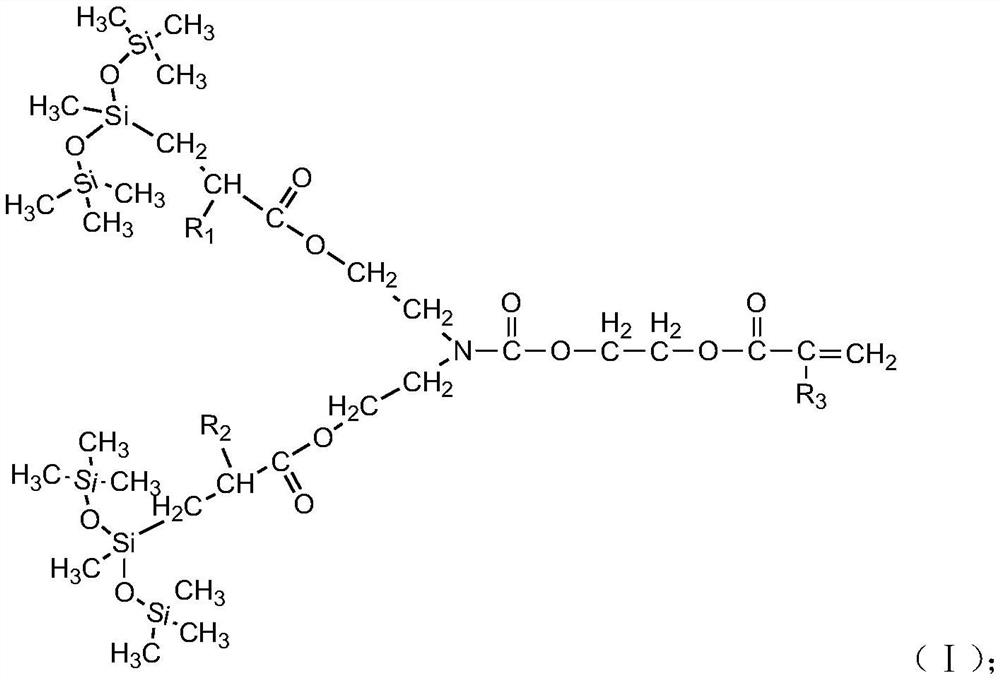

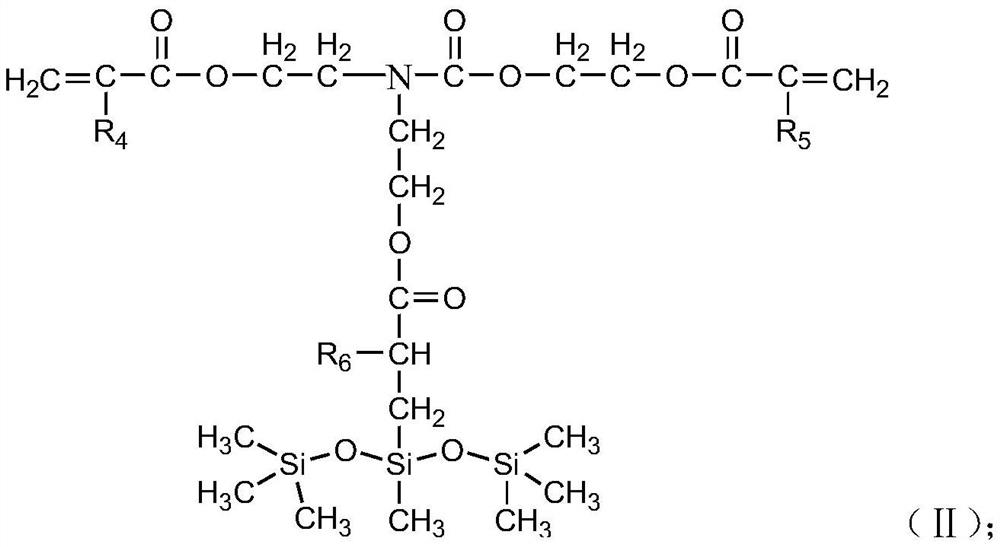

A kind of high-strength and high-toughness water-based antifouling metal baking paint and preparation method thereof

A metal baking paint, water toughness technology, used in antifouling/underwater coatings, biocide-containing paints, coatings, etc. The effect of bonding density, reducing surface tension and friction coefficient, and improving substrate wetting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

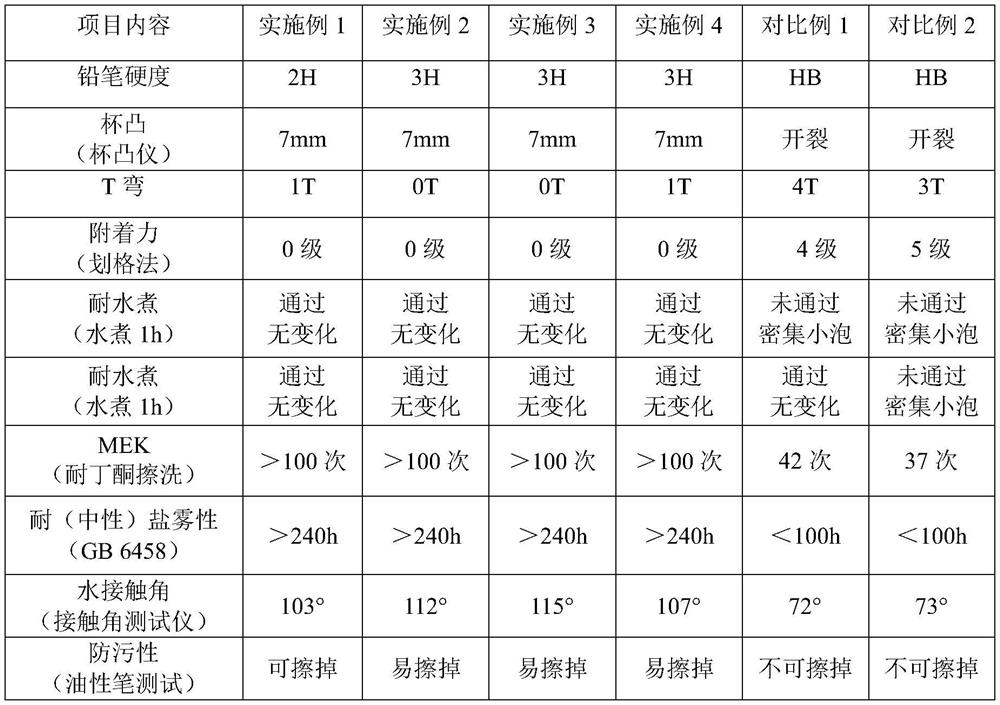

Embodiment 1

[0061] The high-strength and high-toughness water-based antifouling type metal baking varnish of embodiment 1, calculated by mass percentage, this water-based metal baking varnish comprises 50% epoxy-hyperbranched organosilicon co-modified acrylic polyurethane resin, 7% P2100 water-based polyester resin, 2% of saturated polyester polyol (Mn=300), 5% of CYMEL 327 amino resin, 0.5% of YX908 epoxy phosphate, 0.3% of BYK333, 0.5% of ethylene glycol tert-butyl ether, 3% of N,N-dimethylethanolamine, 0.3% blocked p-toluenesulfonic acid catalyst, 0.5% benzotriazole, 0.2% organic silicon defoamer CD68 and the rest of water.

[0062] The above raw materials are mixed and uniformly dispersed to prepare a high-strength and high-toughness water-based anti-fouling metal baking varnish with a solid content of 41.2 wt%.

[0063] In this example, epoxy-hyperbranched silicone co-modified acrylic polyurethane resin is prepared according to the following steps:

[0064] S1: In a four-neck flask ...

Embodiment 2

[0067] The high-strength and high-toughness water-based antifouling type metal baking varnish of embodiment 2, calculated by mass percentage, this water-based metal baking varnish comprises 40% epoxy-hyperbranched organosilicon co-modified acrylic polyurethane resin, 5% P2200 water-based polyester resin, 5% saturated polyester polyol (Mn=500), 10% CYMEL 325 amino resin, 1% YX909 epoxy phosphate, 0.5% BYK307, 2% ethylene glycol tert-butyl ether, 2% 2-amino-2-methyl-propanol, 0.5% blocked dodecylbenzenesulfonic acid catalyst, 0.3% benzotriazole, 0.3% organosilicon defoamer CD68 and the rest water.

[0068] The above raw materials are mixed and uniformly dispersed to prepare a high-strength and high-toughness water-based anti-fouling metal baking paint with a solid content of 44.2 wt%.

[0069] In this example, epoxy-hyperbranched silicone co-modified acrylic polyurethane resin is prepared according to the following steps:

[0070]S1: In a four-neck flask equipped with a condens...

Embodiment 3

[0073] The high-strength and high-toughness water-based anti-fouling metal baking varnish of embodiment 3, calculated by mass percentage, this water-based metal baking varnish includes 30% epoxy-hyperbranched organic silicon co-modified acrylic polyurethane resin, 10% P2100 water-based polyester resin, 8% of saturated polyester polyol (Mn=800), 8% of CYMEL 328 amino resin, 1% of YX909 epoxy phosphate, 0.5% of vinyl tris (β-methoxyethoxy) silane coupling Agent, 0.1% BYK301, 5% ethylene glycol tert-butyl ether, 0.5% triethylamine, 1% blocked dinonyl naphthalene disulfonic acid catalyst, 0.1% benzotriazole, 0.5% organic Silicon defoamer CD68 and the balance of water.

[0074] The above raw materials are mixed and uniformly dispersed to prepare a high-strength and high-toughness water-based antifouling metal baking paint with a solid content of 35.9 wt%.

[0075] In this example, epoxy-hyperbranched silicone co-modified acrylic polyurethane resin is prepared according to the foll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com