A kind of nitrogen-doped porous carbon nanosheet and its preparation method

A nitrogen-doped porous carbon and nanosheet technology, applied in the direction of nano-carbon, can solve the problems of low chemical activity, poor dispersion and ion affinity, achieve uniform size distribution, reduce self-discharge behavior and electronic contact resistance, The effect of narrow pore size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

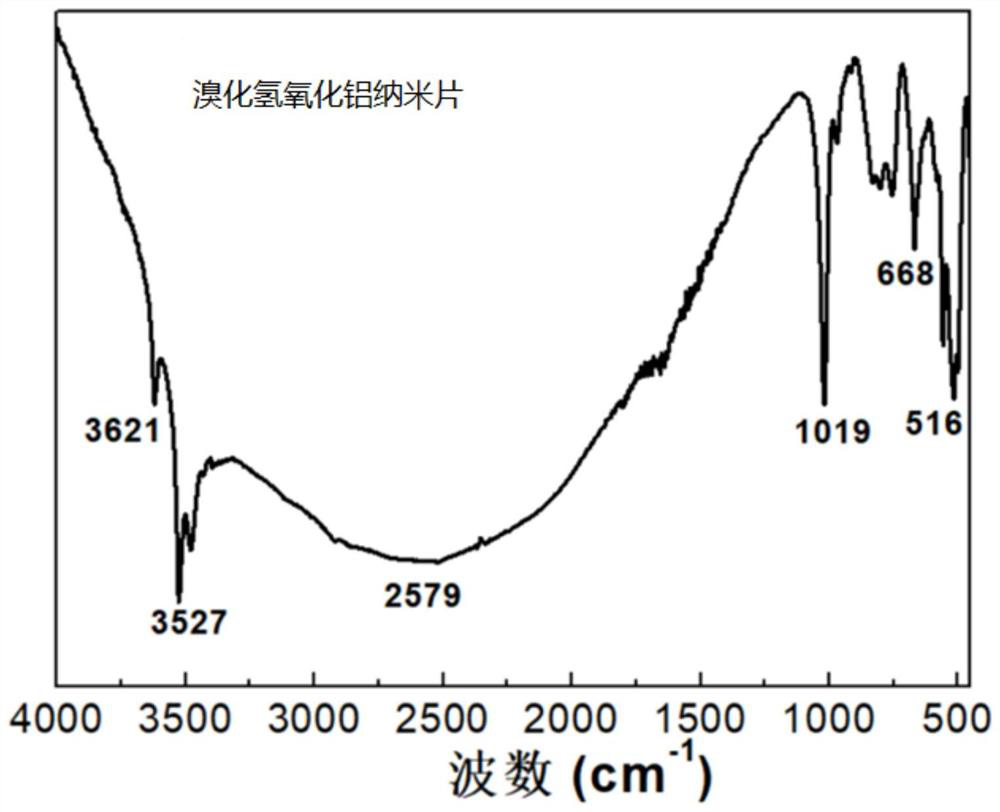

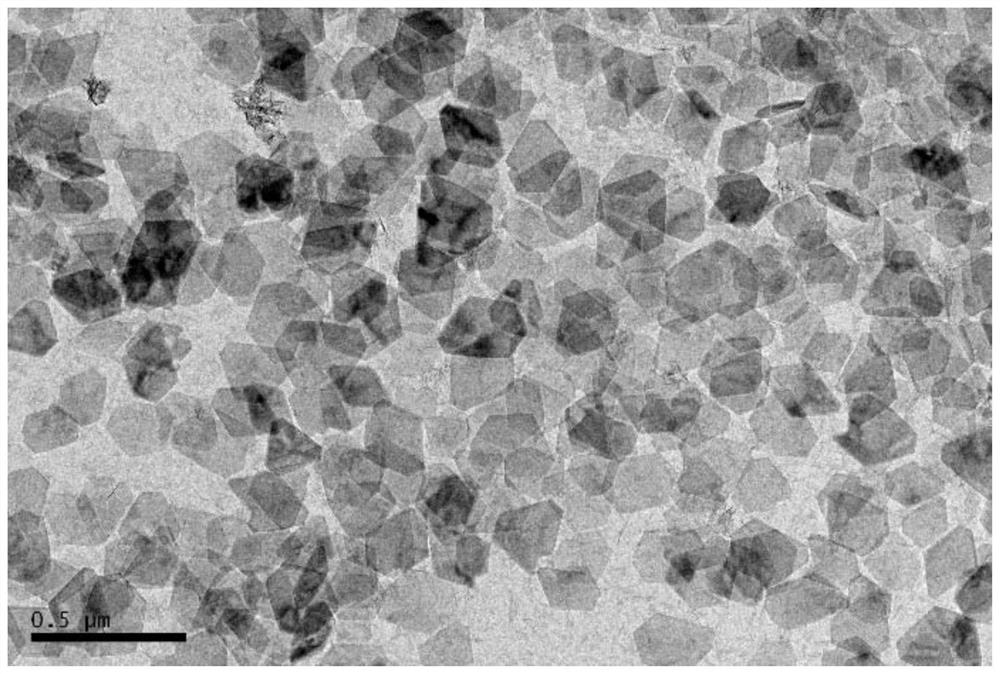

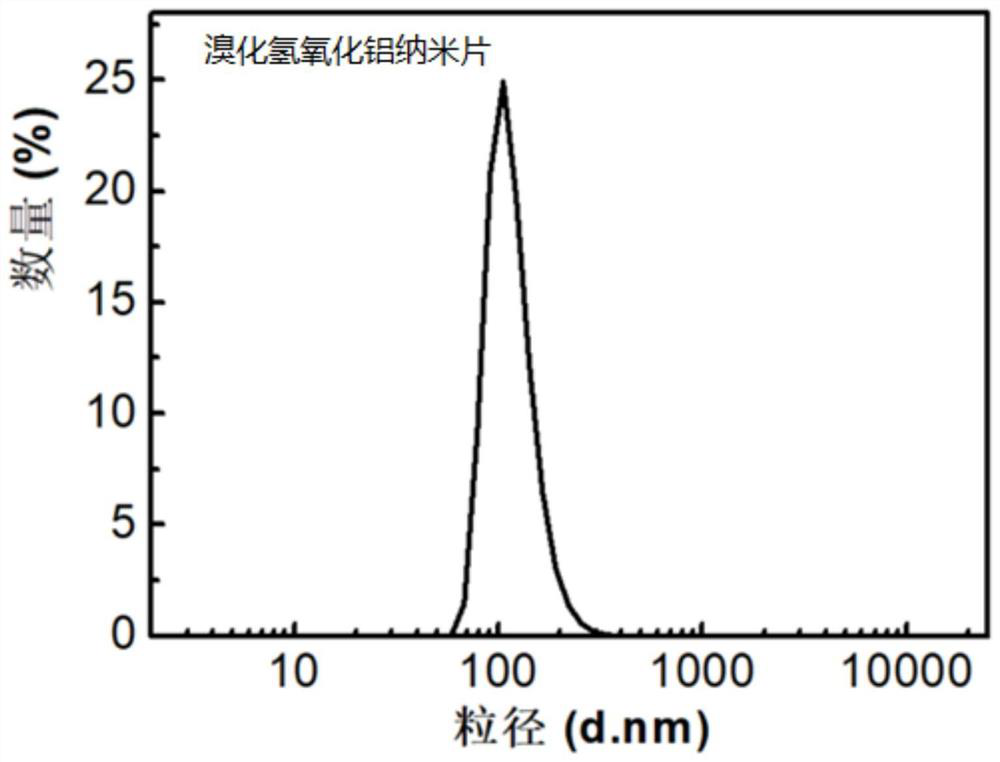

[0033] First dissolve 0.5 g of aluminum sec-butoxide and 0.5 g of aluminum isopropoxide in 10.0 g of water, add 0.05 g of 12-(2-bromoisobutyrylamino)dodecanoic acid, and heat up to 50-80 ℃, react for 2-5h to obtain a reaction solution, and repeat the precipitation and purification of the reaction solution to obtain aluminum bromide nanosheets; then dissolve 10 mg of aluminum bromide nanosheets in N,N-dimethylformamide Then add 10 ml of acrylonitrile, 10 mg of copper bromide and 10 mg of 2,2'-bipyridine. After nitrogen deoxygenation, liquid nitrogen freezing makes the solution solid, then cuprous bromide is added, and the temperature is raised to 60 °C. The polymerization is carried out for 5-12 h, styrene is added, and the reaction is continued for 8-12 h to obtain aluminum hydroxide nanosheets grafted with polyacrylonitrile block polymer; the conversion rate of monomer is determined by nuclear magnetic resonance (NMR) to determine the reaction time. The polyacrylonitrile bloc...

Embodiment 2

[0036] First dissolve 0.5 g of aluminum sec-butoxide and 0.5 g of aluminum isopropoxide in 10.0 g of water, add 0.1 g of α-chloroisobutyric acid, and then heat up to 50-80 °C, and react for 2-5 h to obtain the reaction Then, 10 mg of aluminum hydroxide chloride nanosheets were dissolved in N,N-dimethylformamide, and then 15 ml of acrylonitrile, 10 mg of copper chloride and 10 mg of copper chloride were added. mg 2,2'-bipyridine, after nitrogen deoxygenation, freezing in liquid nitrogen to make the solution solid, adding cuprous chloride, heating to 60 °C for polymerization for 5-12 h, adding methyl methacrylate, and continuing the reaction for 8- 12h, the polyacrylonitrile block polymer grafted aluminum hydroxide nanosheets were obtained; during the polymerization reaction, the conversion rate of monomers was measured by nuclear magnetic resonance (NMR) to determine the reaction time. The polyacrylonitrile block polymer-grafted aluminum hydroxide nanosheets were placed in a po...

Embodiment 3

[0038] First dissolve 0.5 g of aluminum sec-butoxide and 0.5 g of aluminum isopropoxide in 10.0 g of water, add 0.03 g of α-bromoisovaleric acid, and then heat up to 50-80 °C, and react for 2-5 h to obtain the reaction The reaction solution was repeatedly precipitated and purified to obtain aluminum bromide nanosheets; 10 mg of aluminum bromide nanosheets were dissolved in N,N-dimethylformamide, and 20 ml of acrylonitrile and 10 mg of bromine were added. Copper compound and 10 mg 2,2'-bipyridine, after nitrogen deoxygenation, liquid nitrogen freezing to make the solution solid, adding cuprous bromide, heating to 60 °C for polymerization for 5-12 h, adding butyl acrylate, and continuing the reaction 8-12h, the polyacrylonitrile block polymer-grafted aluminum hydroxide nanosheet is obtained; during the polymerization reaction, the conversion rate of the monomer is determined by nuclear magnetic resonance (NMR) to determine the reaction time. The polyacrylonitrile block polymer-g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com